Automatic tube falling device for coiler and using method thereof

An automatic doffing and winding machine technology, which is applied in the field of chemical fiber filament production, can solve the problems that the production volume affects the quality and efficiency of the filament tube, the labor intensity of workers is high, and the production line is difficult to transform, so as to achieve small occupied space and easy transformation. , The effect of low requirements on the use environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

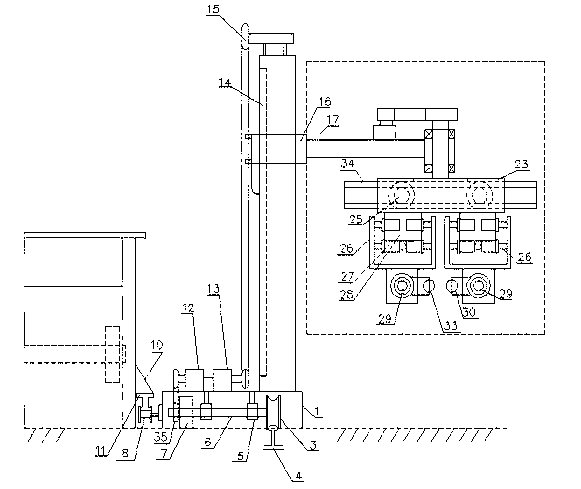

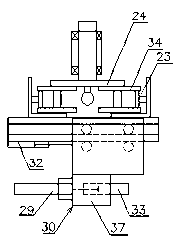

[0035] see Figure 1-4 , which shows a schematic diagram of an automatic doffing device for a winding machine and its usage method according to the present invention. Such as figure 1An automatic doffing device for a winding machine is shown, including a position control device, a doffing moving device and an upper thread shaft device, and the position controlling device is connected to the doffing moving device through a cross arm 17 . The position control device includes a horizontal control device and a vertical control device. The horizontal control device includes: a running trolley 1, a rail wheel 3 and a trolley reducer motor 12, and the running trolley 1 controls the track wheel 3 to move forward or backward through the trolley reducer motor 12 The vertical regulating device comprises: column 2 and moving slide block 16 up and down, and moving slide block 16 up and down adjusts the height on column 2 by the rotation of chain on sprocket shaft 15, and moving slide bloc...

Embodiment 2

[0056] Example 2: Please refer to Figure 5 , an automatic doffing device for a winding machine and its use method. In this embodiment, its structure and method are similar to those of Embodiment 1, the difference is that: two symmetrically arranged on the vertical control device For the doffing moving device, the upper wire shaft device on each doffing moving device corresponds to a winding machine. In this way, two doffing moving devices can be symmetrically arranged on the column, which is beneficial to the balance of the equipment on the one hand, and realizes two times of doffing on the same winding machine through the movement of the trolley.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com