Lifting appliance path optimization control system used for container gantry crane

A gantry crane and path optimization technology, which is applied to safety devices, transportation and packaging, load hanging components, etc., can solve the problems of identification, positioning and path optimization algorithms that are not practical, reliability is difficult to guarantee, and calculation time is long, etc., to achieve Improve operating efficiency, reduce box collision accidents, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

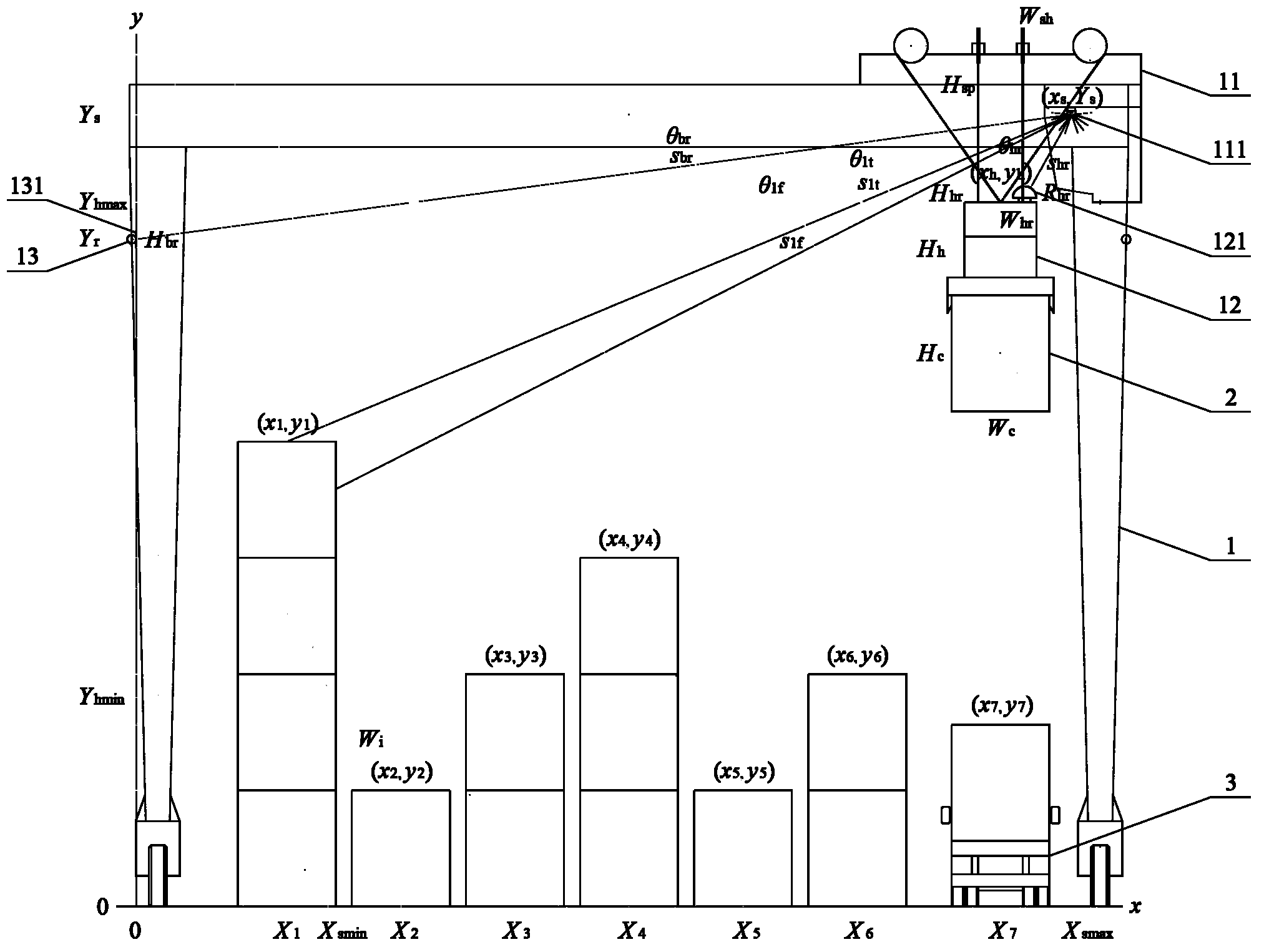

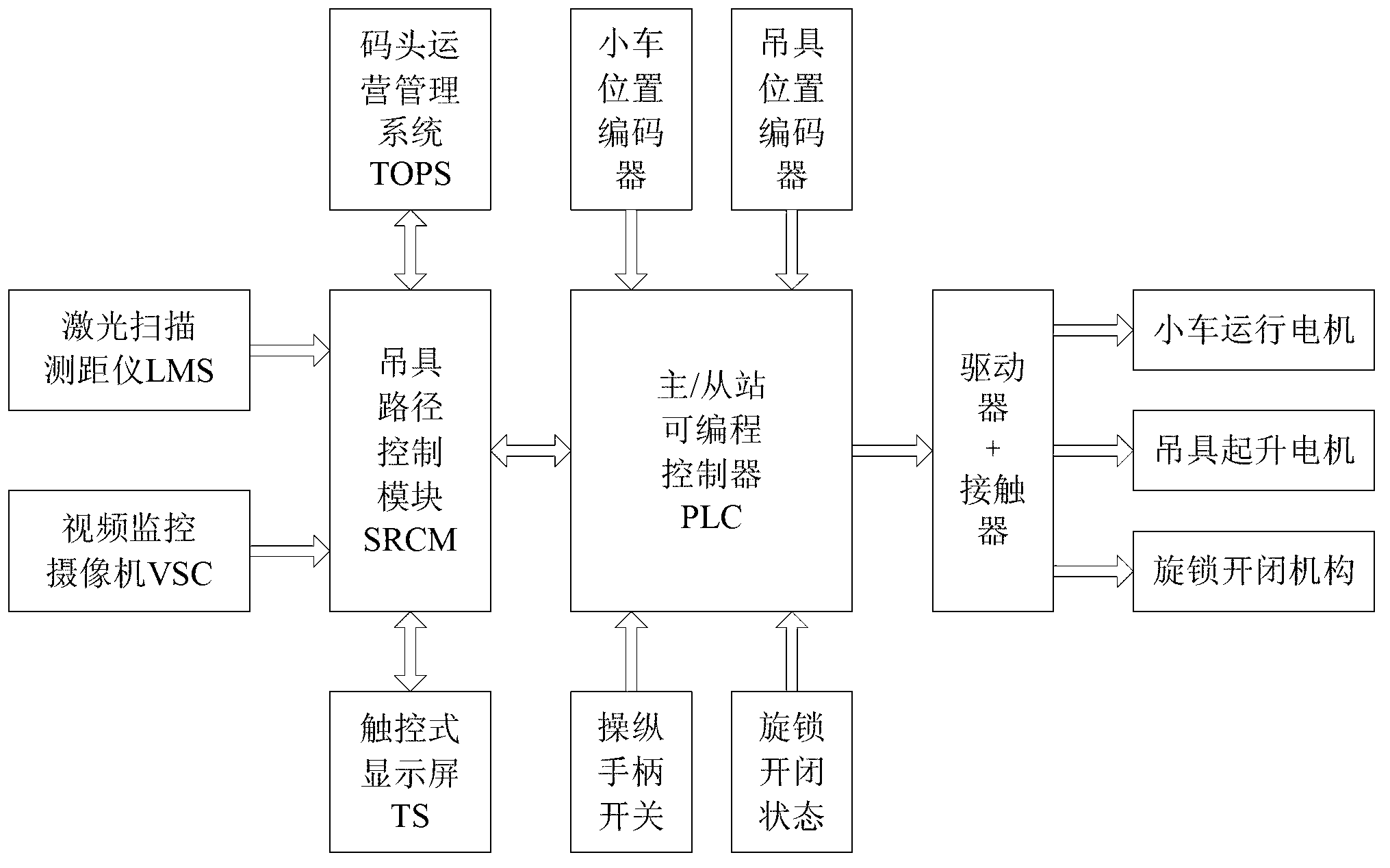

[0012] in figure 1 In the illustrated embodiment, the automatic loading and unloading operation of the tire crane in the container yard of the present invention mainly involves: tire crane (1), container (2), truck (3), trolley (11), spreader (12), beam ( 13) Laser scanning rangefinder (111), spreader reflector (121), beam reflector (131) and other components, among which: yard containers are stacked longitudinally under the tire crane in order, and the truck channel is located below the tire crane. On the side, the trolley runs horizontally on the top track of the tire crane, the spreader is connected to the lifting mechanism on the trolley through a sling, the beam is at the upper position of the tire crane leg, the beam reflector is installed vertically on the beam, and the spreader reflector is horizontal Installed on the spreader frame, the laser scanning rangefinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com