High-density fermentation culture medium for haemophilus parasuis and preparation method for same

A high-density fermentation technology of Haemophilus suis, which is applied in the high-density fermentation medium of Haemophilus parasuis and its preparation field, can solve the problems of high medium cost, shortened culture time, and poor effect, and achieve cost reduction, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

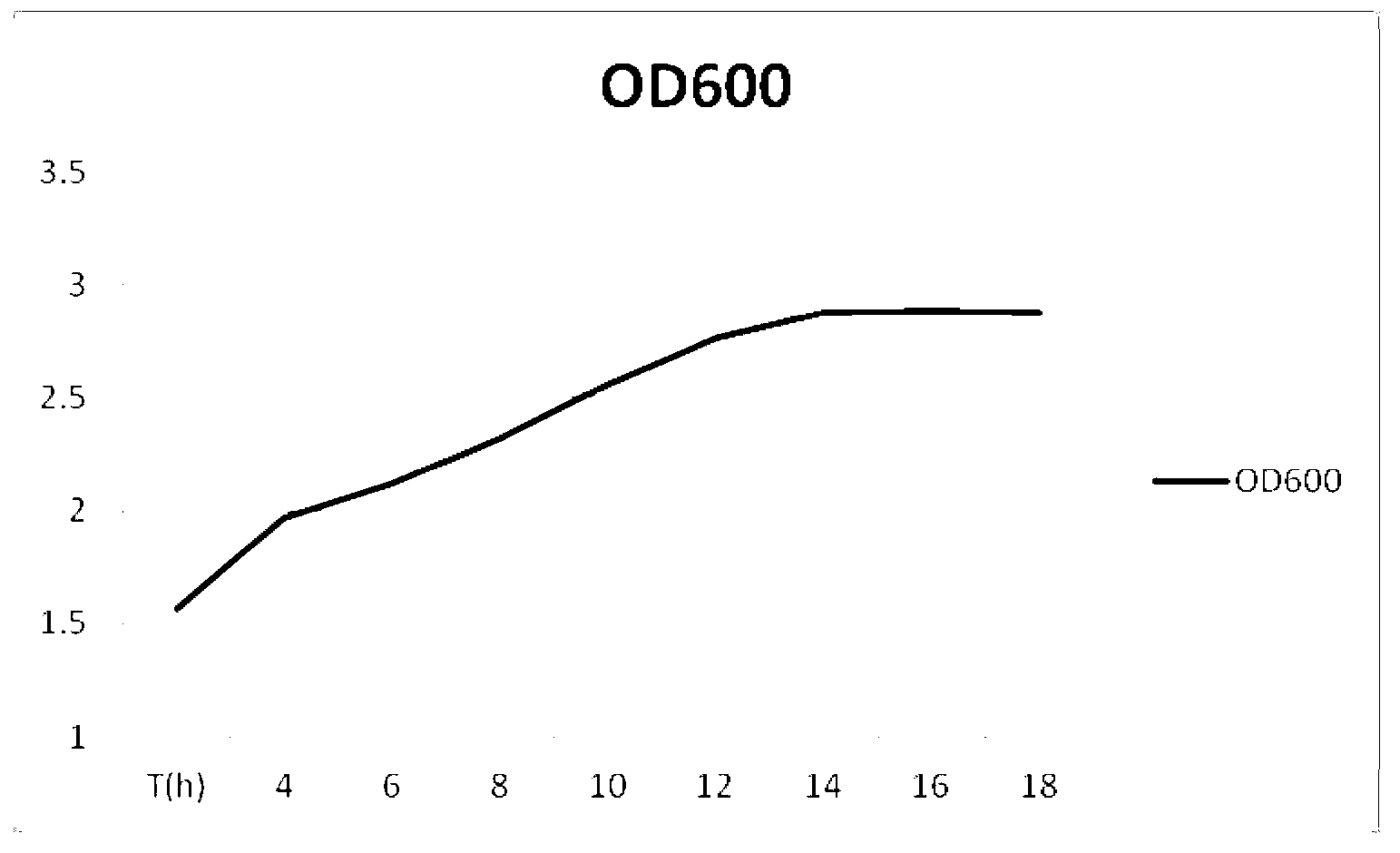

Embodiment 1

[0021] Preparation of medium:

[0022] (1) Take yeast powder 10g / L, soybean peptone 1g / L, NaCl 2g / L, K 2 HPO 4 1g / L, dissolved in distilled water and adjusted to 1000ml, adjusted the pH of the medium to 7.0~7.4, and sterilized under high-pressure steam at 115~121°C for 20~30min;

[0023] (2) Take 1~10g of maltose, add distilled water to make up to 1000ml, make maltose solution, and sterilize under high-pressure steam at 115~121℃ for 20~30min;

[0024] (3) According to the volume ratio, take 1% of the maltose solution in step B, filter sterilized bovine serum 2%, NAD 0.001%, and the balance is the sterilized medium of step A to obtain Haemophilus parasuis High-density fermentation medium.

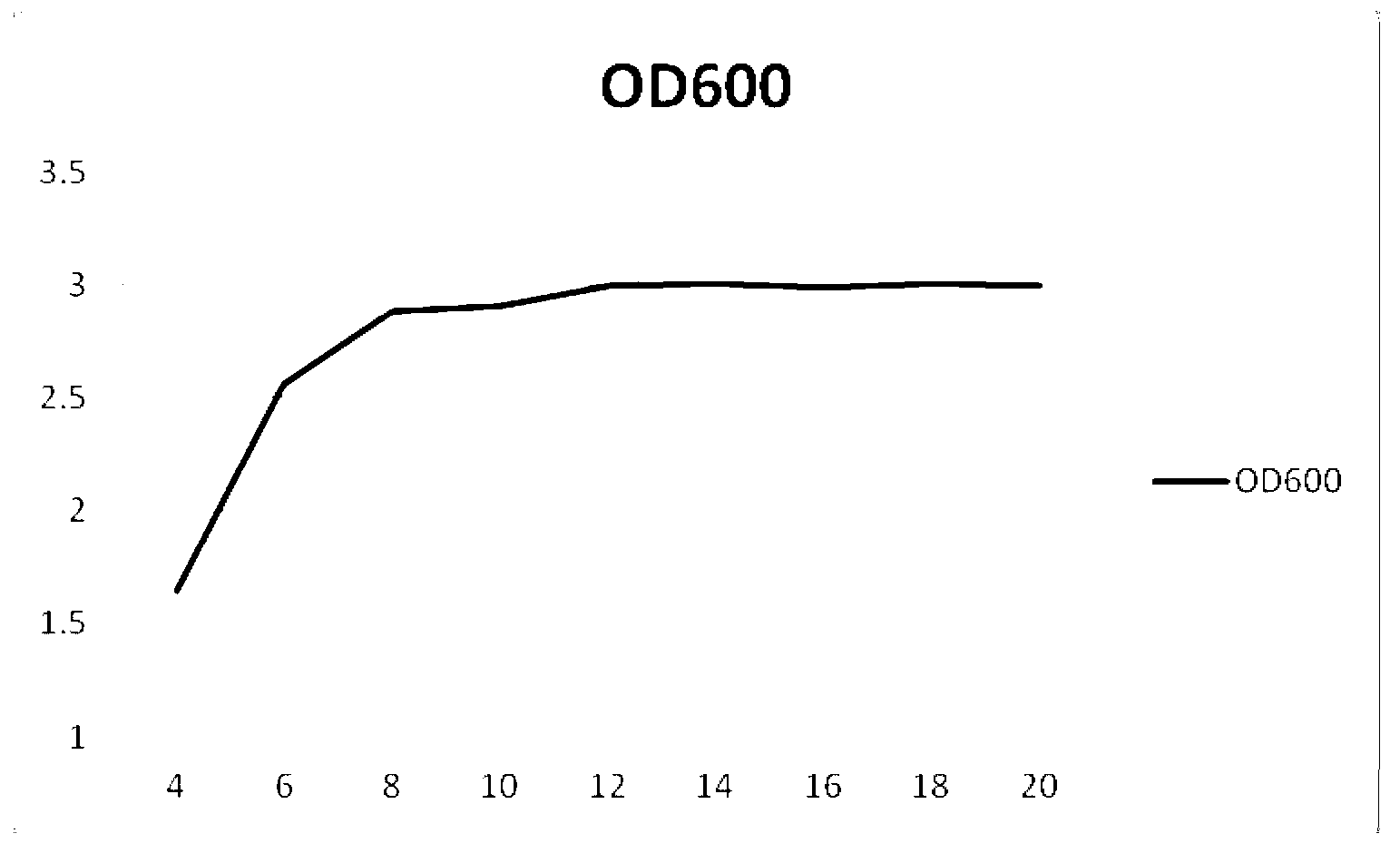

Embodiment 2

[0025] Embodiment 2: the preparation of optimization medium

[0026] (1) Take yeast powder 16g / L, soybean peptone 5g / L, NaCl 5g / L, K 2 HPO 4 5g / L, dissolved in distilled water and adjusted to 1000ml, adjusted the pH of the culture medium to 7.0~7.4, and sterilized under high-pressure steam at 115~121°C for 20~30min;

[0027] (2) Take 1~10g maltose, add distilled water to make up to 1000ml, and make maltose

[0028] Solution, sterilized under high pressure steam at 115~121℃ for 20~30min;

[0029] (3) According to the volume ratio, take 5% of the maltose solution in step B, 5% of filter-sterilized bovine serum, and 0.005% of NAD, and the balance is the sterilized medium of step A to obtain Haemophilus parasuis High-density fermentation medium.

Embodiment 3

[0030] Embodiment 3: the preparation of optimization medium

[0031] (1) Take yeast powder 30g / L, soybean peptone 10g / L, NaCl 10g / L, K 2 HPO 4 10g / L, dissolved in distilled water and adjusted to 1000ml, adjusted the pH of the medium to 7.0~7.4, and sterilized under high-pressure steam at 115~121°C for 20~30min;

[0032] (2) Take 1~10g of maltose, add distilled water to make up to 1000ml, make maltose solution, and sterilize under high-pressure steam at 115~121℃ for 20~30min;

[0033] (3) According to the volume ratio, take 10% of the maltose solution in step B, 10% of filter-sterilized bovine serum, and 0.01% of NAD, and the balance is the sterilized medium of step A to obtain Haemophilus parasuis High-density fermentation medium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com