Method for grouting and floor lifting by directional drilling machine

A technology of grouting lifting and drilling rig, applied in the field of geotechnical engineering, can solve problems such as high cost, influence on hole layout, influence on floor quality, etc., and achieve the effect of easy control of lifting effect, reduction of slurry cost, and low drilling cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

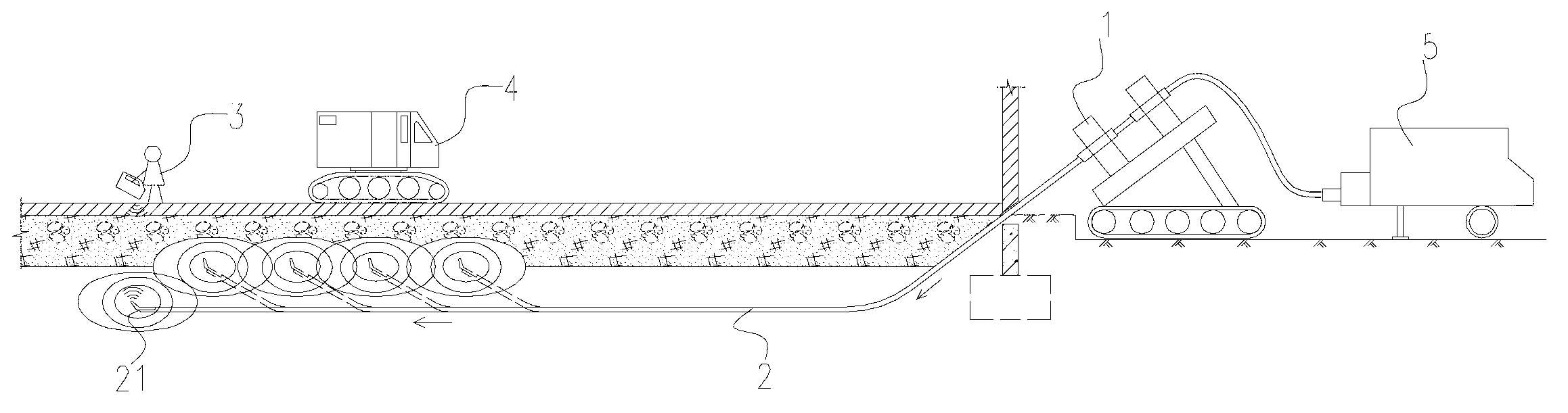

[0026] see figure 1 , a kind of guiding drilling rig grouting lifting method that the present invention provides, comprises guiding drilling rig 1 and drill pipe 2, the mixed slurry that mud mixes with admixture and high-pressure grouting pump 5 and drill guide 3, its The characteristic is to include the following construction steps:

[0027] A. to detect and remove obstacles

[0028] B. The inclined plane drill bit 21 of the pilot drilling machine drills holes and advances the drill rod 2

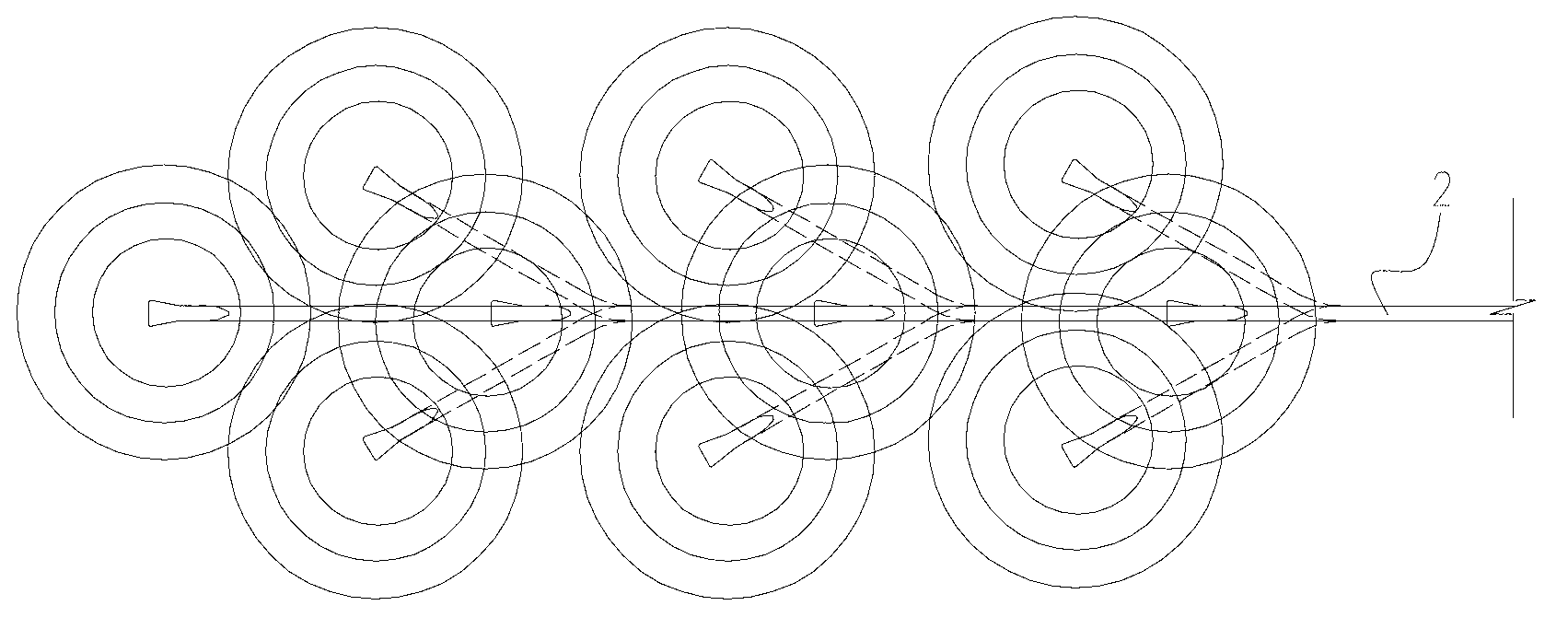

[0029] C. The drill guide device controls the propulsion direction of the inclined-plane drill bit of the guide drilling rig, thereby adjusting the drill pipe line, reaching the grouting position, and passing the mixed slurry through the drill pipe with the high-pressure grouting pump 5 Perform fixed-point grouting

[0030] D. Repeat step C to inject grout at each predetermined position under the floor

[0031] E. Exit the drill pipe after the floor is raised.

[0032] The directional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com