Shale oil content forecasting method for Log-delta T logging evaluation

A prediction method, mud shale technology, applied in the field of well logging exploration, can solve the problems of low neutron and relatively low, achieve the effect of rapid calibration, cancel the tedious and difficult process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

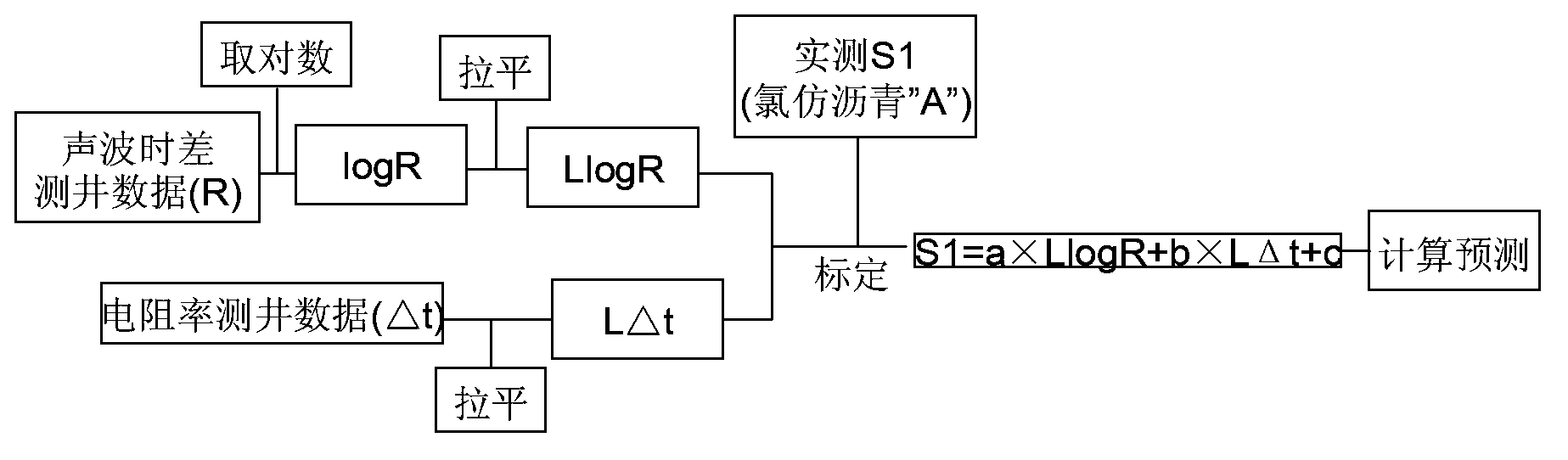

[0038] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 As shown, a logR-ΔT logging evaluation method for shale oil content prediction,

[0039] Shale formation oil content S 1 The steps for evaluating predictions are:

[0040] Step 1. Logging parameter preprocessing:

[0041] ① Extract acoustic transit time logging data ΔT and resistivity logging data R. The unit of ΔT is milliseconds per foot (μs / ft), and the unit of R is ohm-meter (Ω·m).

[0042]② Take the logarithm of the resistivity R to obtain logR;

[0043] Step 2. Node identification:

[0044] Identify the local minimum value from the resistivity R log curve and the acoustic time difference ΔT log curve, and remove the influence of non-residual hydrocarbon-containing intervals; mathematically, the method of derivation is usually used to find the minimum value, so It is necessary to derive the log curve;

[0045] The formula for calculating the first derivative of logR at the i-th depth point is:

...

Embodiment 2

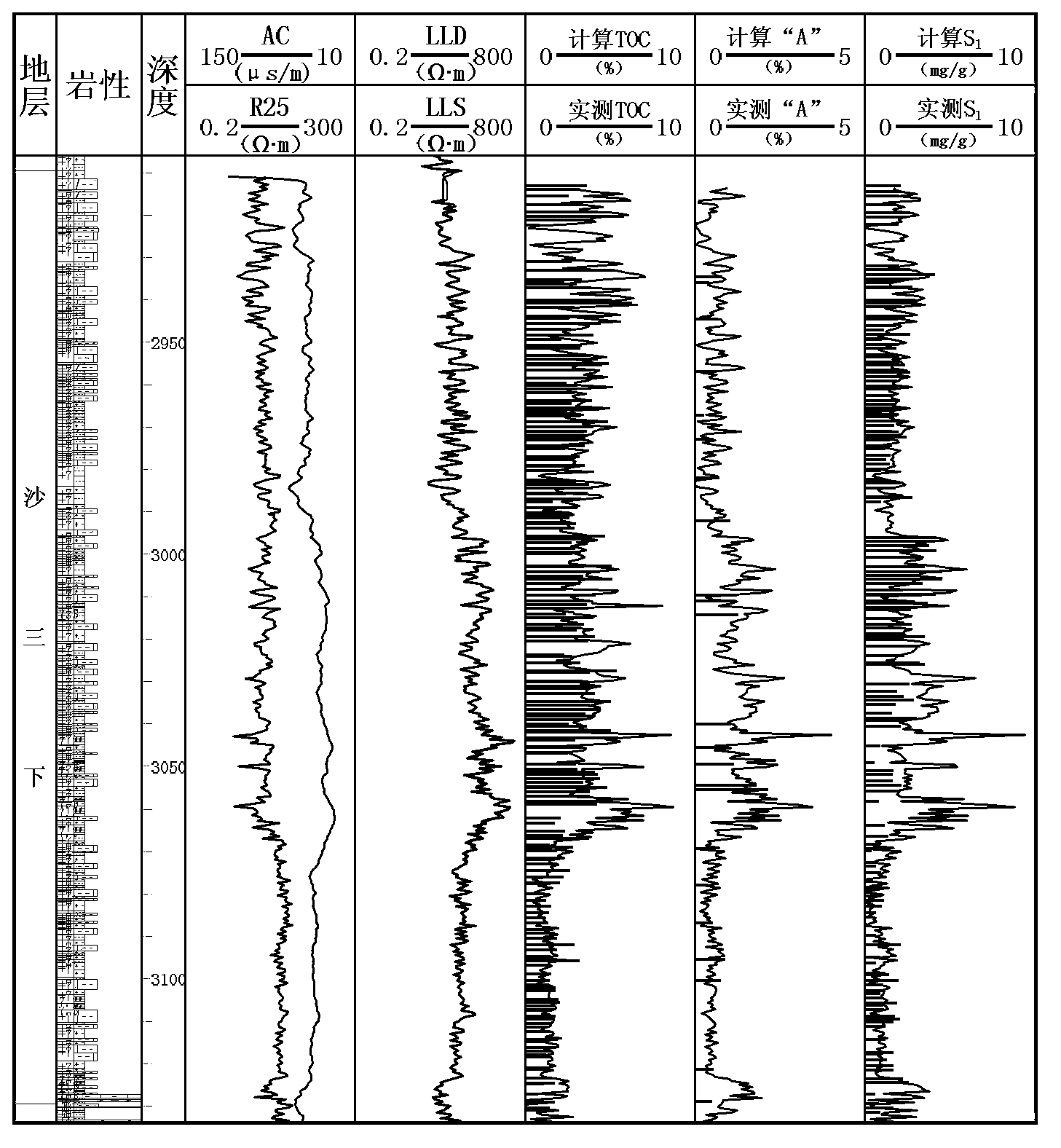

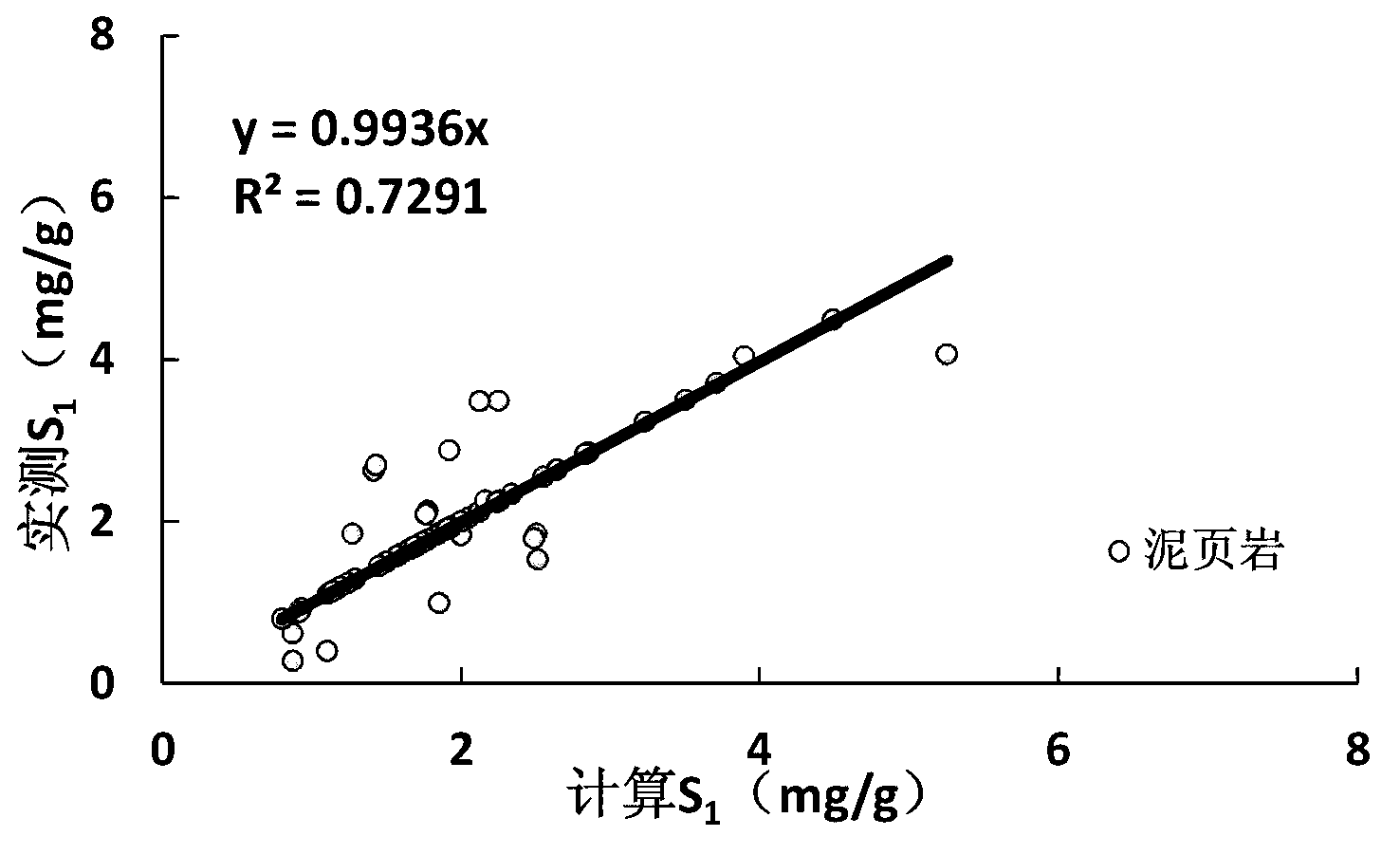

[0079] Embodiment 2: as figure 1 , figure 2 , image 3 , Figure 4 As shown, a LogR-ΔT logging evaluation method for shale oil content prediction is illustrated by taking Well Luo 69 in the Bonan subsag as an example, and the following steps are adopted:

[0080] 1. Logging parameter preprocessing

[0081] ① Extract acoustic transit time logging data ΔT and resistivity logging data R. The unit of ΔT is milliseconds per foot (μs / ft), and the unit of R is ohm-meter (Ω·m).

[0082] ② Take the logarithm of the resistivity R to obtain logR;

[0083] 2. Node identification

[0084] From the resistivity R logging curve and the acoustic time difference ΔT logging curve, the local minimum value is identified, and the influence of the non-residual hydrocarbon layer is removed. The method of derivation is usually used to find the minimum value in mathematics, so the derivation of the logging curve is required;

[0085] The calculation formula of the first derivative of logR at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com