Klingelnberg bevel gear fault diagnosis method based on sensitive IMF (instinct mode function) components

A fault diagnosis and gear technology, applied in the fault diagnosis of Klingenberg bevel gears, based on sensitive IMF in the field of fault diagnosis of Klingenberg bevel gears

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

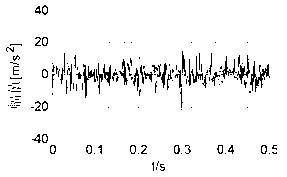

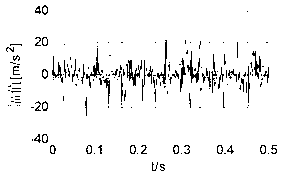

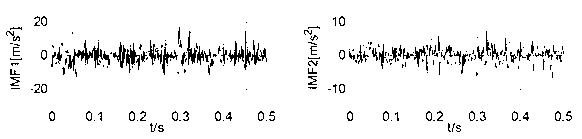

[0041] The flowchart of a Klingenberg bevel gear fault diagnosis method based on sensitive IMF in the embodiment of the present invention is as follows: figure 1 As shown, the steps of the present invention will be described in detail below in conjunction with the flow chart. The specific implementation steps are as follows:

[0042] The first step: use the acceleration sensor to measure the Klingenberg bevel gearbox, and collect the gear acceleration vibration signal as the signal to be analyzed;

[0043] Step (1): Layout and related parameters of the signal acquisition system

[0044] figure 2 A schematic diagram of the layout of the signal acquisition system. like figure 2As shown in , the acquisition system mainly includes three parts, the first part is the motor M that provides power for the system, and the speed of the motor is controlled by the speed controller to ensure the speed requirements of the gears in the system; the second part is the power transmission p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com