Training system for operation technicians of professional devices

A technology of professional equipment and training system, which is applied in the field of technician skill training and assessment, can solve problems such as unfavorable rapid growth of trainees, reduce the risk and cost of real machine operation, and expensive equipment, so as to avoid actual machine operation errors, improve the speed of technology mastering, The effect of overcoming cognitive deficits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

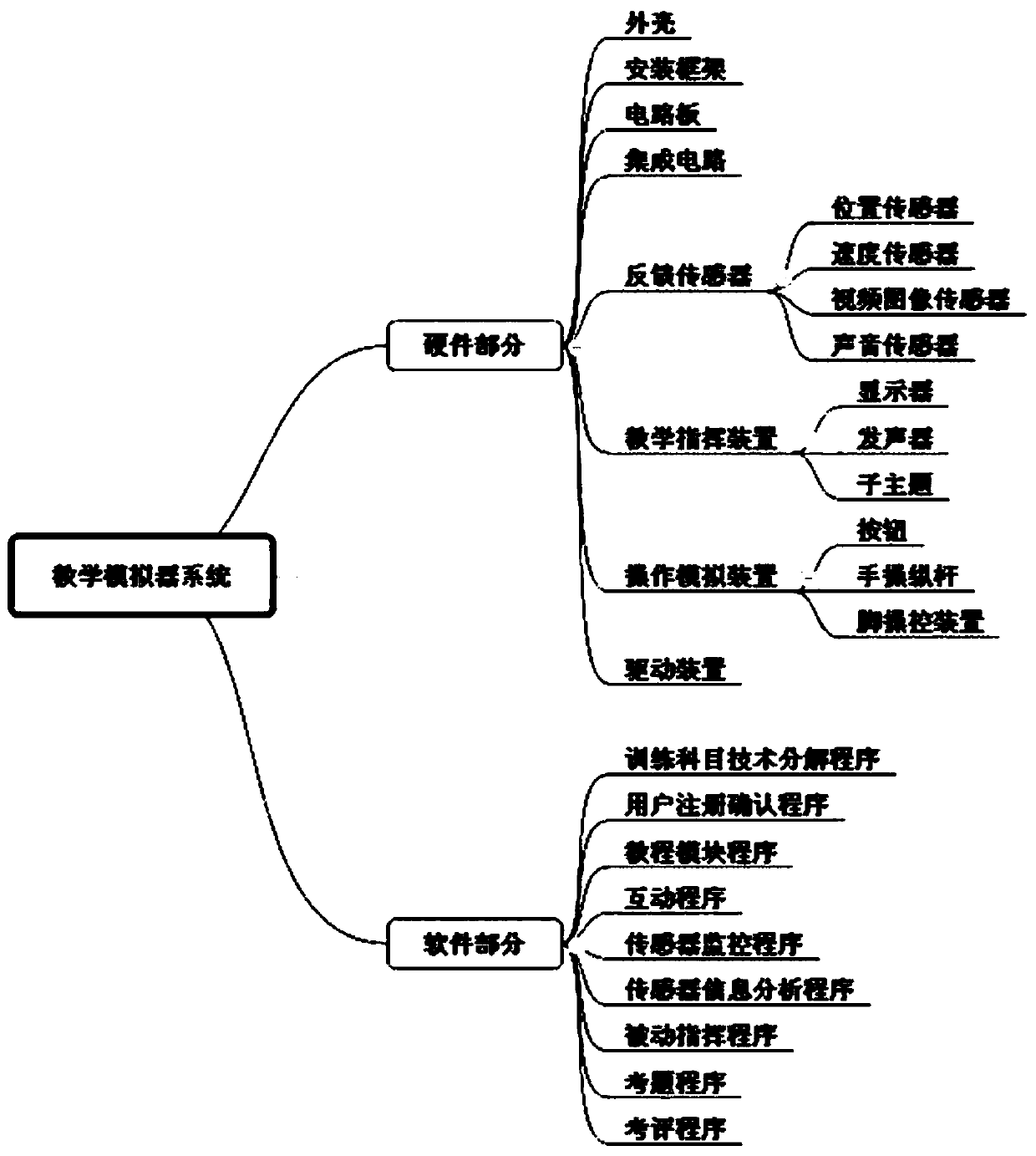

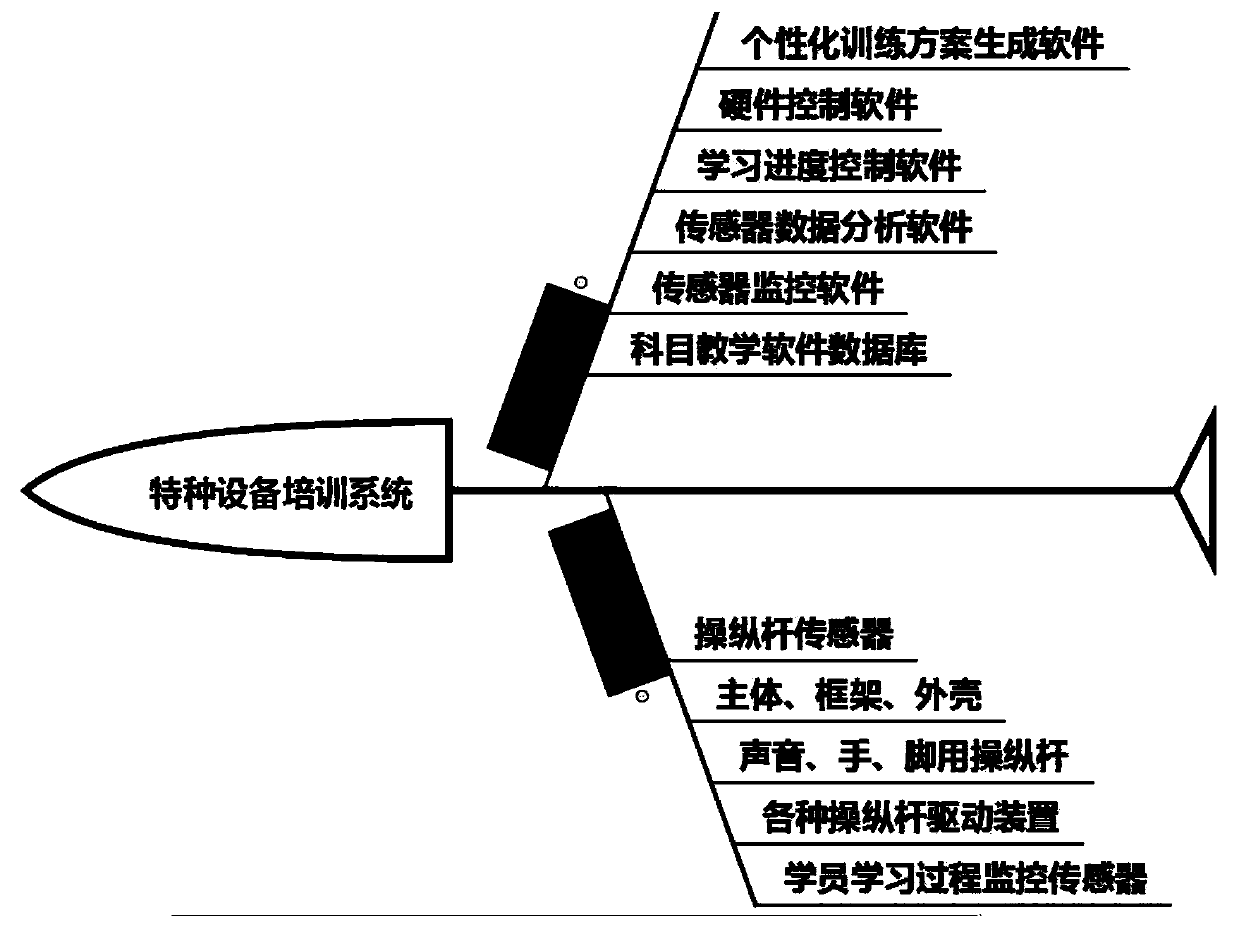

Method used

Image

Examples

specific Embodiment

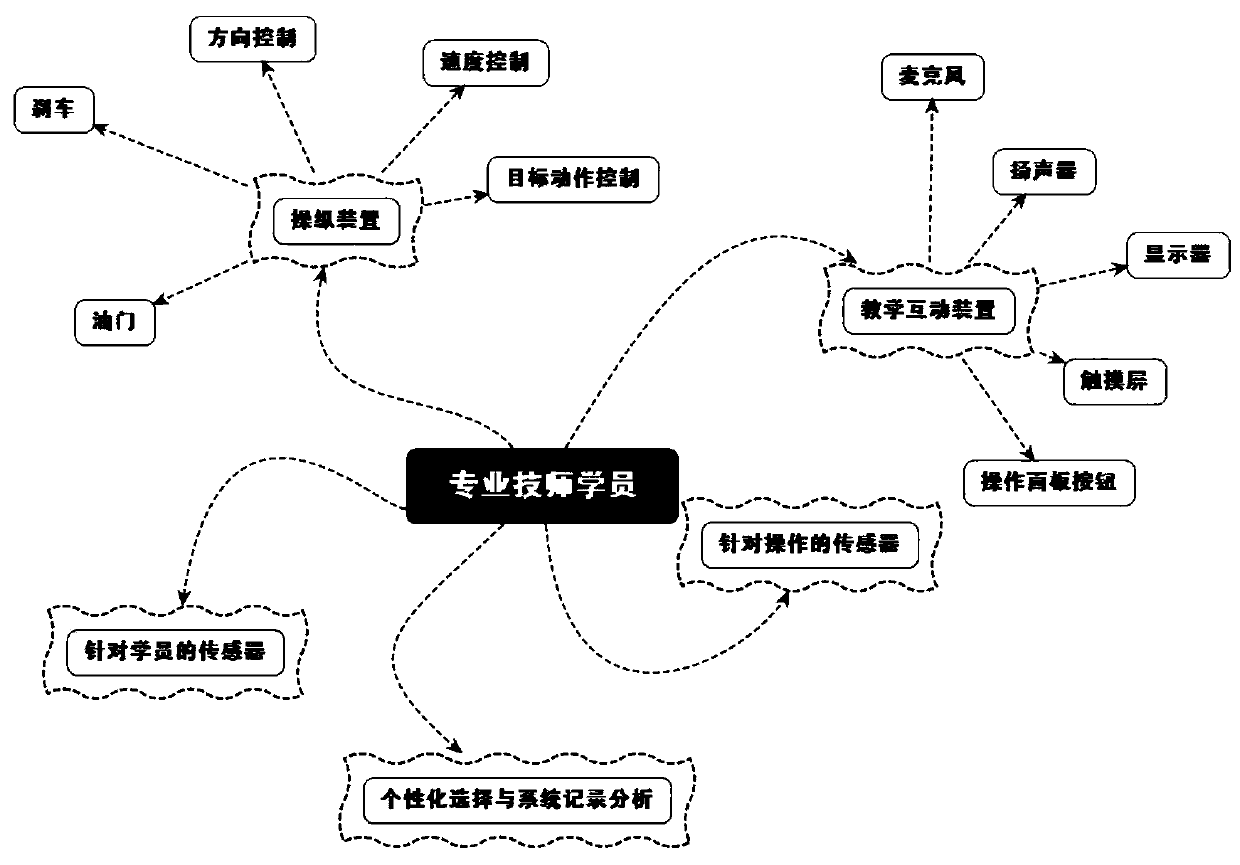

[0064] The special technician training organization purchases and installs the device of the present invention, recruits students from outside, and conducts training. The trainees first enable the training user module in the device, and obtain the distinguishing features of the trainees through hardware input modules such as cameras, mics, and fingerprint recognition devices, and use them for trainee registration. , Record the learning process and human-computer communication process, and provide personalized special training modules to accumulate raw materials for students to do targeted training;

[0065] The training institution assigns courses or the students choose courses actively, and the system starts the course reading and writing module to obtain the data of each optional training subject in the course; the technical decomposition and explanation module of the training subjects: uses and shows the detailed composition and main points of the training subjects to the stu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com