Experimental method for determining fusion characteristics of coal ash for spraying

An experimental method and technology of coal injection, applied in the investigation phase/state change and other directions, can solve the problems of slow heating speed, relatively far heating speed difference, low experimental efficiency, etc., achieve fast heating speed, prevent chemical reaction, and experimental temperature high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

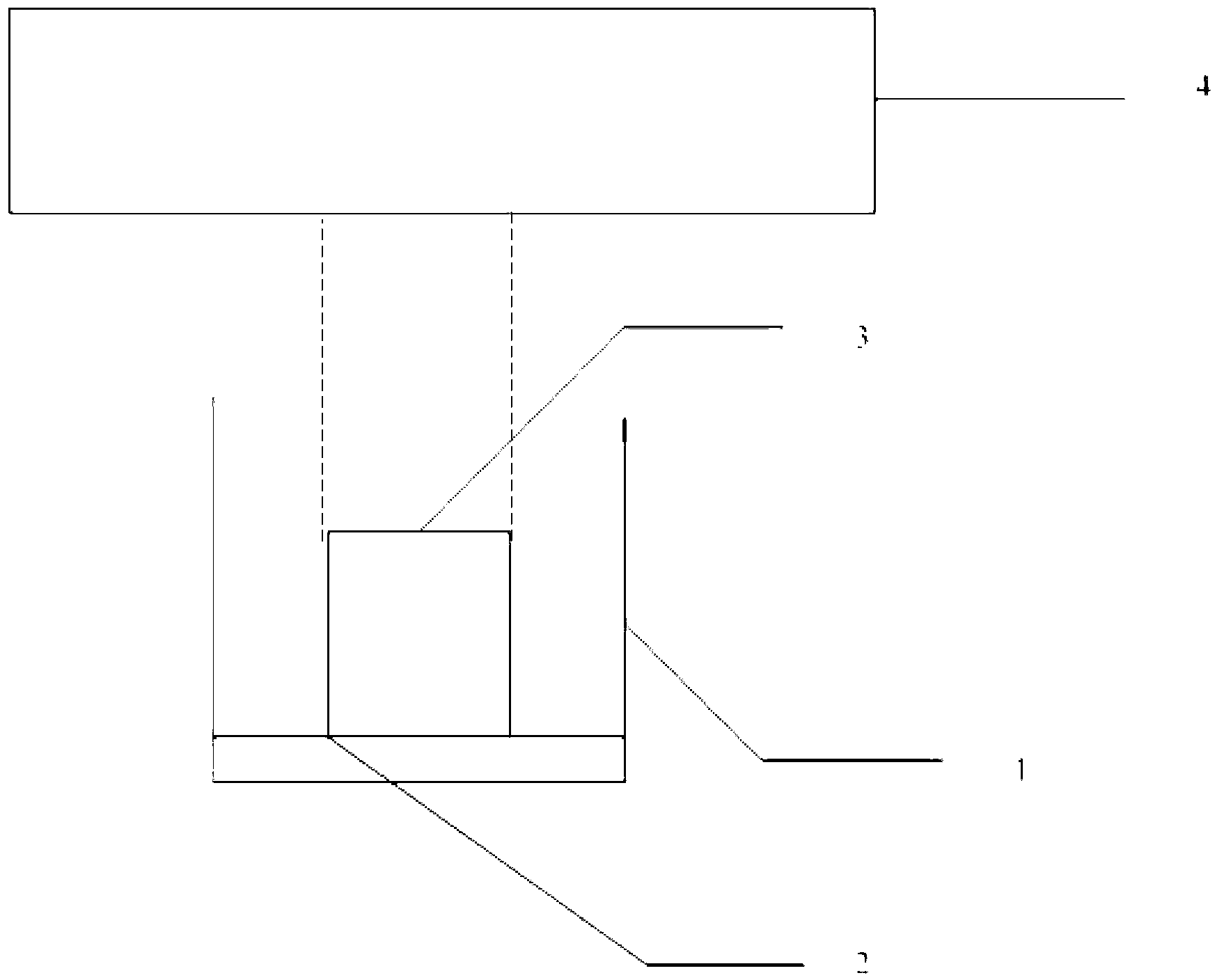

[0013] see figure 1 , an experimental method for determining the melting characteristics of pulverized coal ash provided in the embodiments of the present application, comprising the following steps:

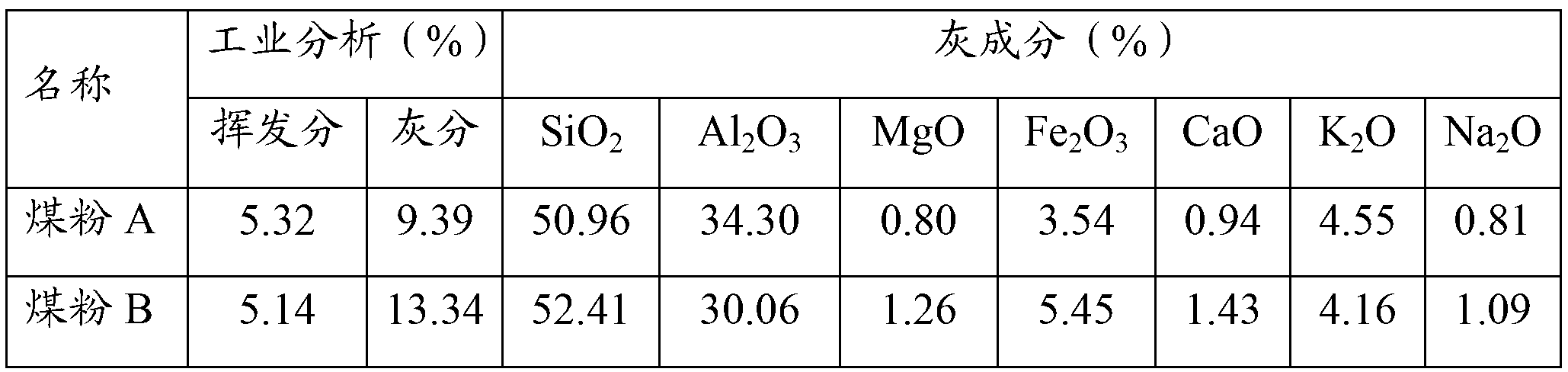

[0014] Step 10: Calcining the coal powder to make a coal ash mass, specifically: using a muffle furnace to calcinate the coal powder into coal ash, and using an agate mortar to grind the coal ash to a particle size below 0.1 mm. Drop dextrin solution into the ground coal ash to make the coal ash plastic, and take 0.8-1.2g plastic coal ash to make a cylinder-shaped coal ash mass 3 .

[0015] Step 20: Place the coal ash cluster under a high-temperature confocal laser scanning microscope to observe the morphological change process of the coal ash cluster 3, and determine the initial coal ash deformation temperature, initial liquid phase formation temperature, and liquid phase complete melting temperature of the coal ash cluster 3 , specifically: place coal ash ball 3 on platinum s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com