Ultrasonic TOFD (Time of Flight Diffraction) detection method for weld defects based on linear frequency modulation technology

A technology of linear frequency modulation and detection method, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, which can solve the problem of conflict between signal propagation distance and resolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

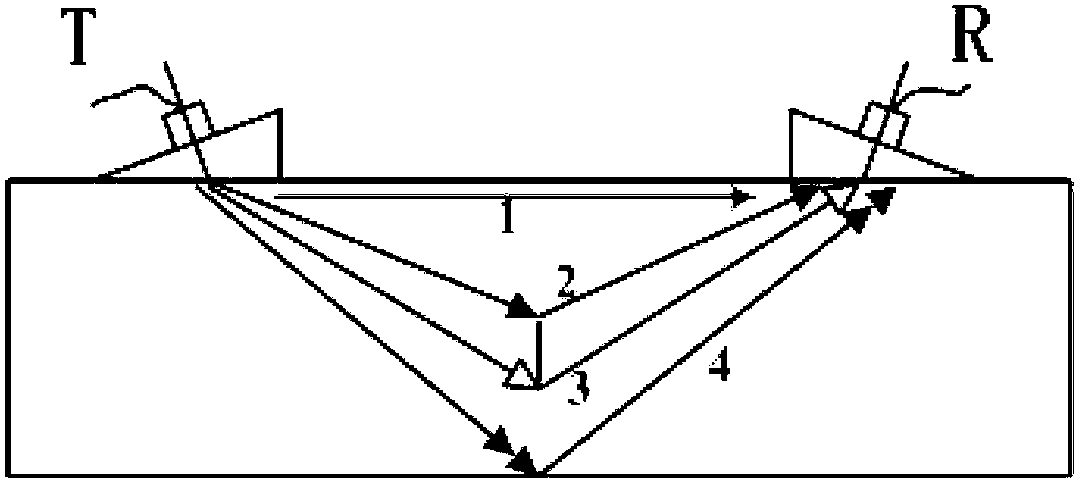

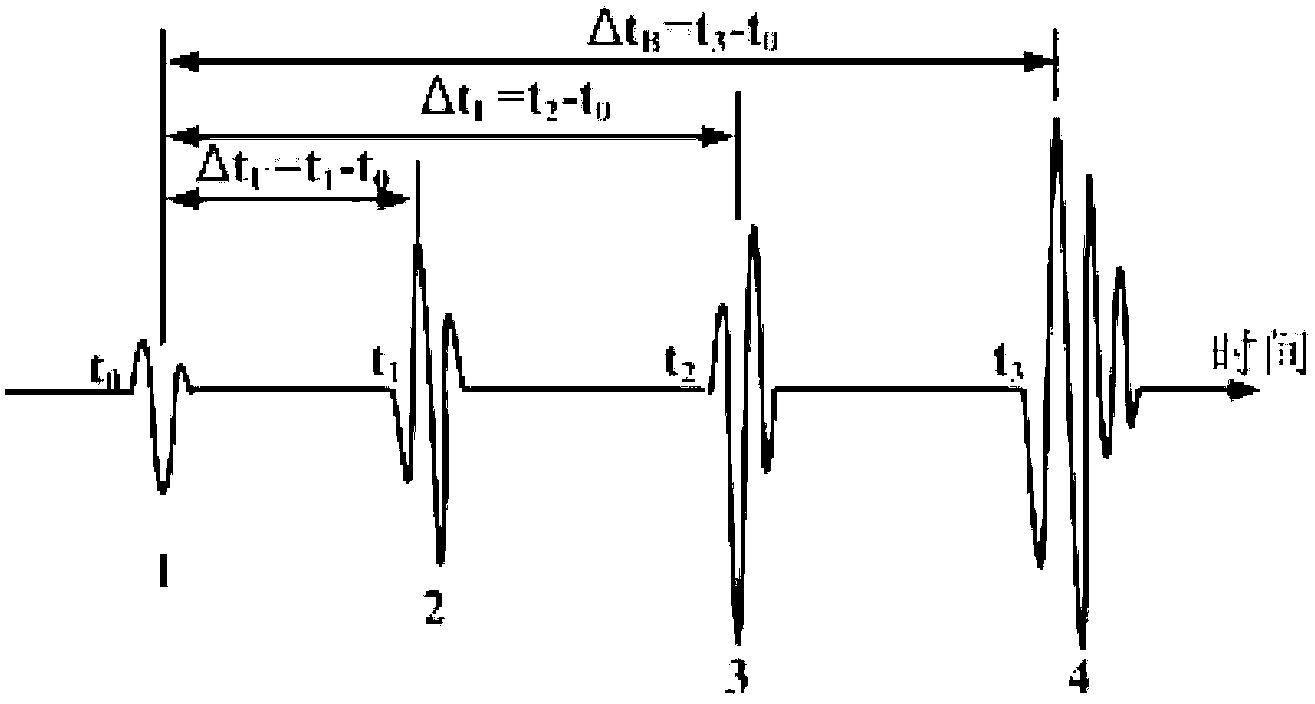

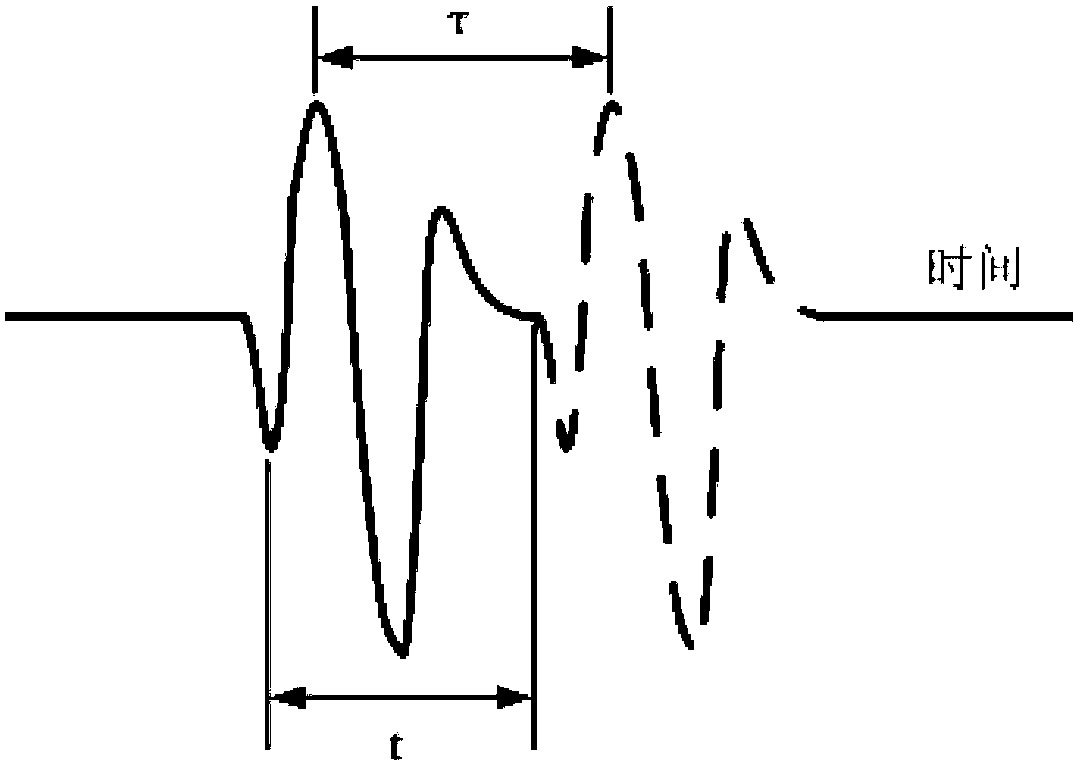

[0054] Specific implementation mode one: combine Figure 4 Describe this embodiment, the method of this embodiment includes the following steps: step 1, the ultrasonic transmitting probe and the receiving probe are symmetrically distributed on both sides of the detected position, the preferred digital signal generator generates a broadband LFM pulse signal, and simultaneously generates a synchronous trigger signal for excitation Broadband signal receiver, the wideband LFM pulse signal is amplified by a linear power amplifier to have the corresponding energy to excite the ultrasonic transmitting probe;

[0055] The LFM pulse signal is generated by a digital method, and the mathematical expression of the linear frequency modulation signal is

[0056] s(t)=Arect(t / T)cos(2πf c t±Kπt 2 ) |t|≤T / 2 (3)

[0057] where A is the signal amplitude, f c is the carrier frequency, K=B / T is the change slope of the instantaneous frequency of the signal, that is, the frequency modulation slo...

specific Embodiment approach 2

[0089] Specific implementation mode two: combination figure 1 Describe this embodiment, the broadband signal receiver of this embodiment is UT-350 broadband signal receiver, can receive the signal of relatively wide frequency band, its highest sampling frequency is 50MHz. Other implementation steps are the same as those in the first embodiment.

specific Embodiment approach 3

[0090] Specific implementation mode three: combination figure 1 This embodiment will be described. The linear power amplifier in this embodiment is a linear power amplifier A150, which can linearly amplify an input signal with a gain of 53 dB. Other implementation steps are the same as those in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com