Display device, color film substrate and manufacturing method of color film substrate

A color filter substrate and a manufacturing method technology, applied in optics, instruments, nonlinear optics, etc., can solve problems such as uneven color pixel layers, affecting the flatness of the film surface in the color filter substrate, affecting product quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

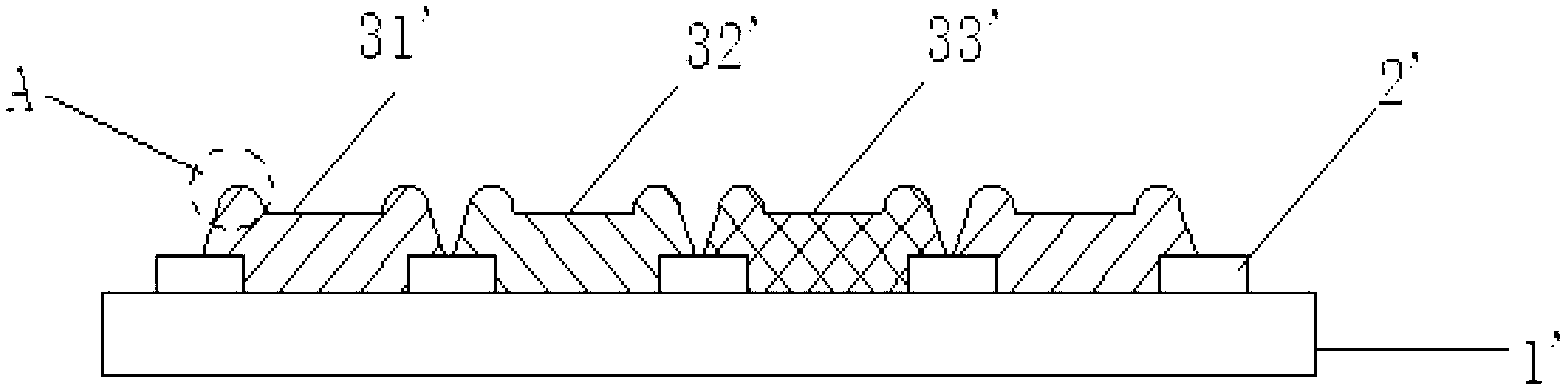

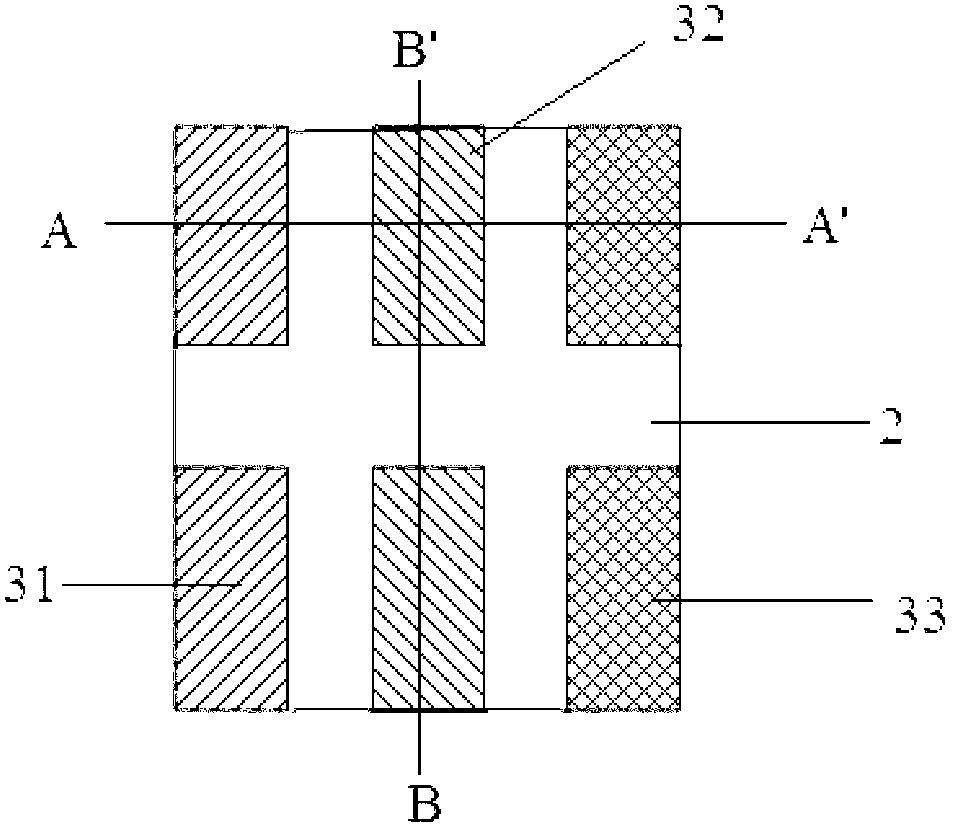

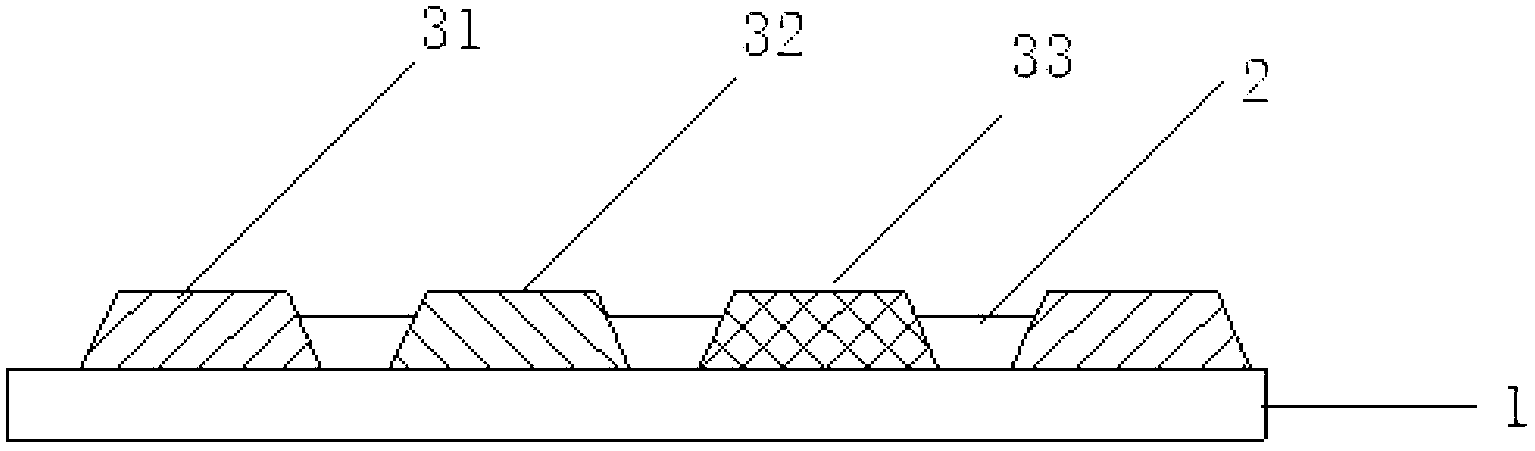

[0038] Such as figure 2 As shown, this embodiment takes TN (Twisted Nematic, twisted nematic) mode as an example, the color filter substrate includes: a substrate 1; a color pixel area, which includes a plurality of pixel units, and the pixel units include at least red sub-pixel units 31. The blue sub-pixel unit 33 and the green sub-pixel unit 32; the sub-pixel units of each color in the pixel unit are arranged at intervals on one side of the substrate 1; the black matrix 2 is arranged between the sub-pixel units of each color.

[0039] Wherein, the material of the substrate 1 can be transparent materials such as glass, quartz, resin, etc., which is not limited here. In...

Embodiment 2

[0049] Such as Figure 6 As shown, the embodiment of the present invention provides a method for manufacturing the above-mentioned color filter substrate, which includes:

[0050] Step S10, using a patterning process to form a color pixel area on the substrate, which includes a plurality of pixel units, and the pixel units at least include a red sub-pixel unit, a blue sub-pixel unit and a green sub-pixel unit; each color in the pixel unit The sub-pixel units are arranged on one side of the substrate at intervals.

[0051] In this step, sub-pixel units including a red sub-pixel unit 31 , a green sub-pixel unit 32 , and a blue sub-pixel unit 33 are formed on the substrate 1 by coating a color photoresist, exposing and developing. Since the sub-pixel units of each color are all fabricated on one side of the substrate 1, the flatness of the side surface is flatter than that of the sub-pixel units of each color arranged on the black matrix 2, and the “bull horn” phenomenon existin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com