Permanent-magnet slip transmission mechanism

A transmission mechanism and slip technology, which is applied in electromechanical transmissions, generators/motors, electromechanical devices, etc., can solve problems such as large volume, complex system mechanism, and large heat dissipation problems, and achieve the effect of small volume and simplified system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

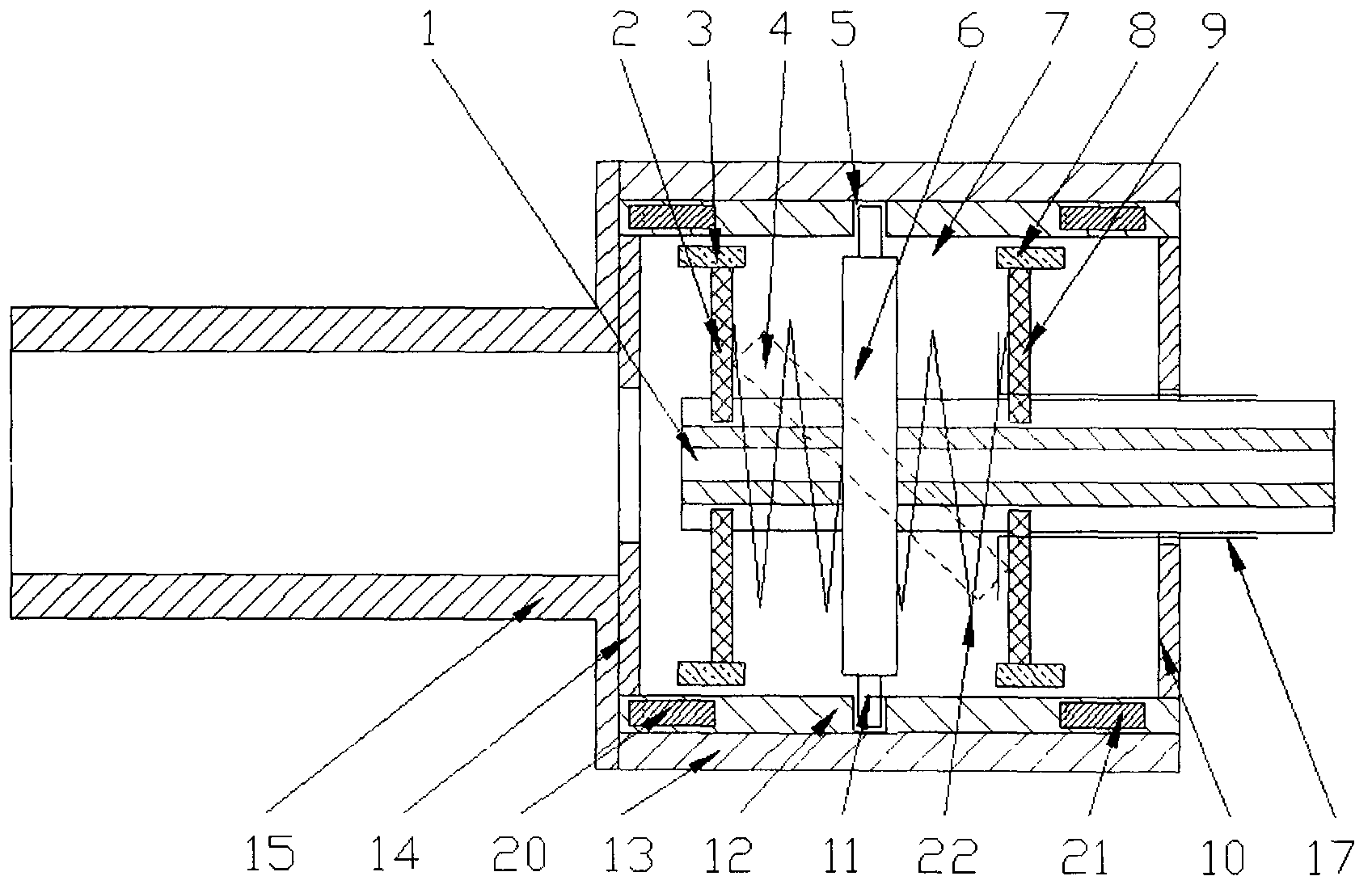

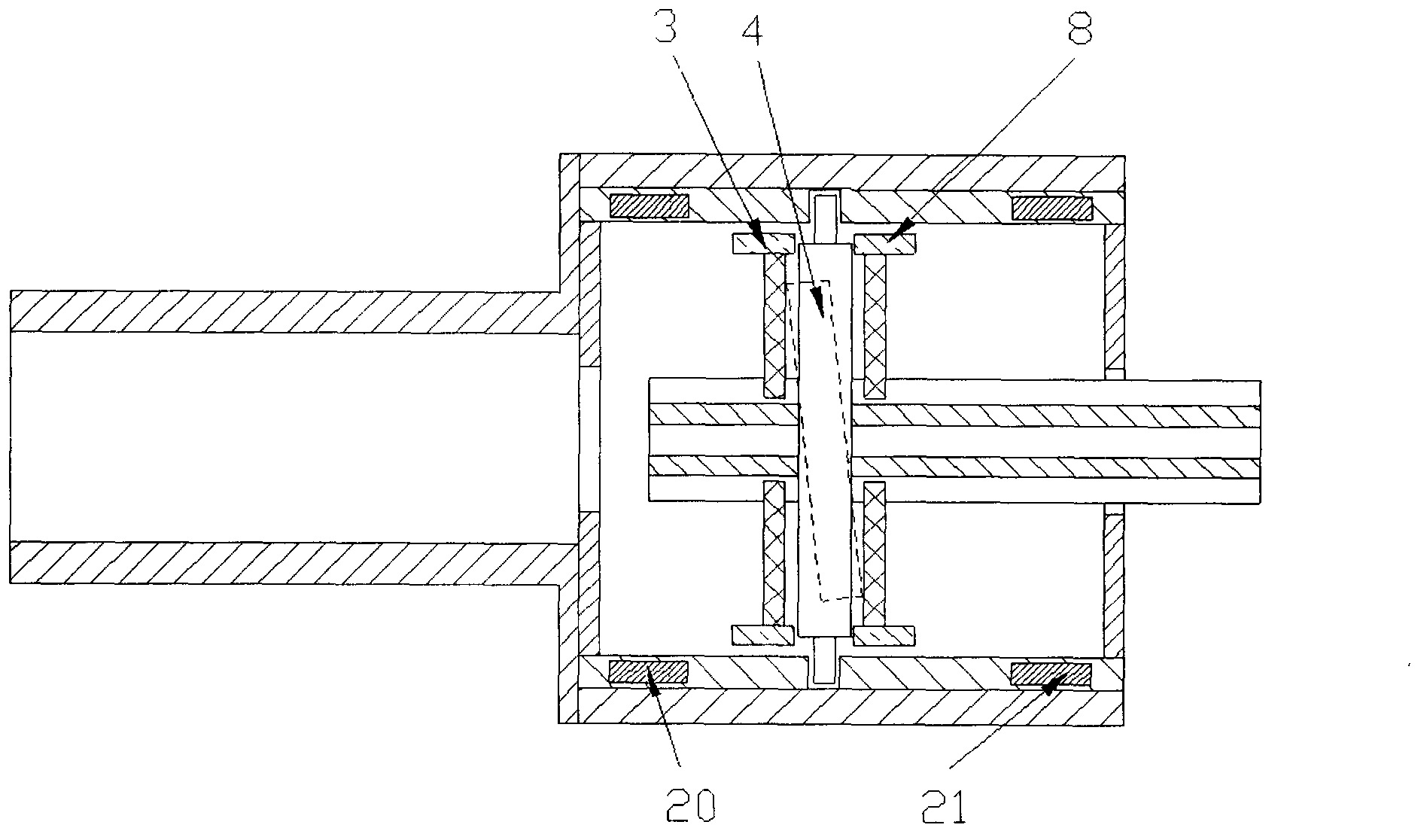

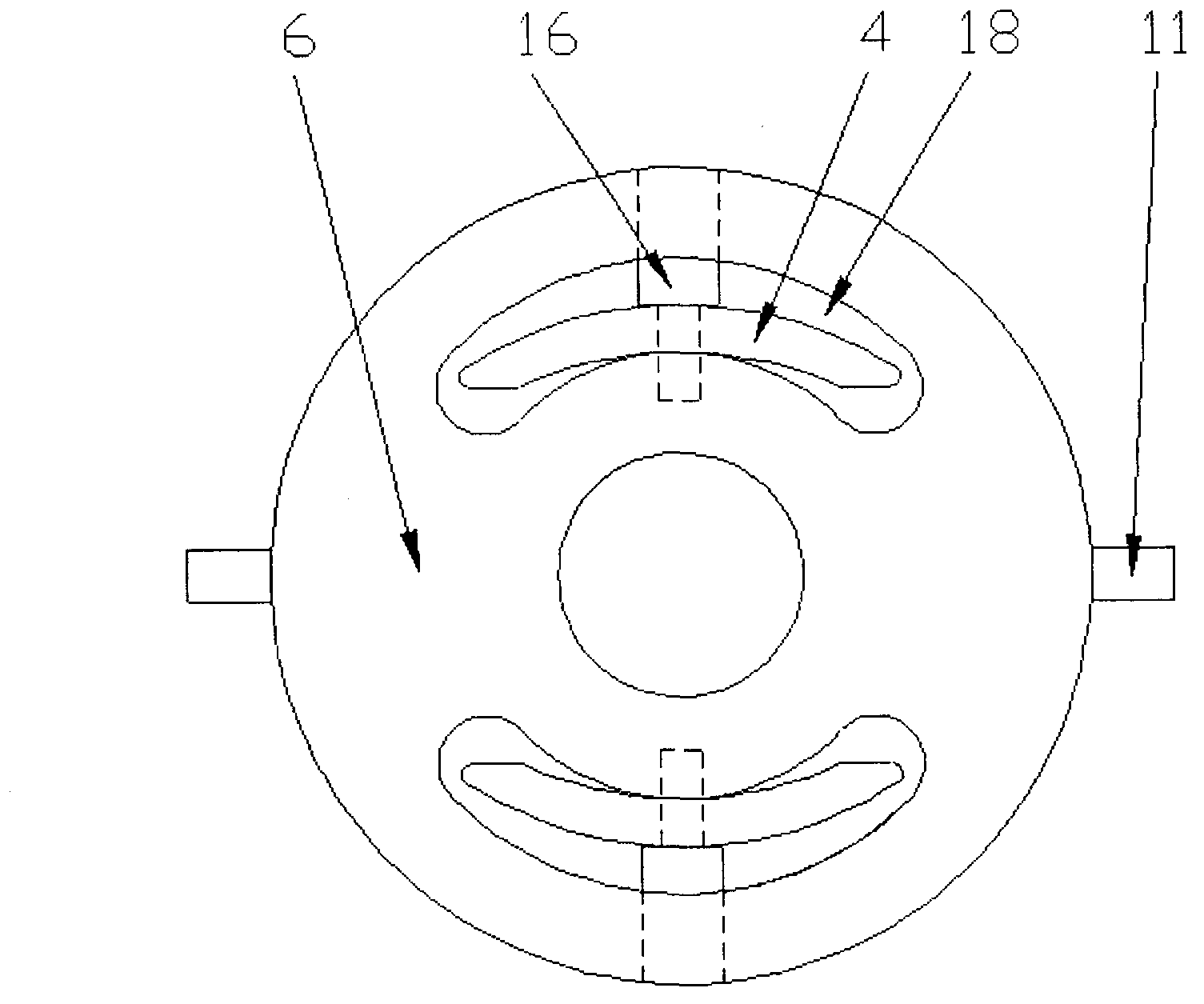

[0023] Refer to attached figure 1 ~ attached Figure 8 , the structural characteristics of a permanent magnet slip transmission mechanism are (as attached figure 1 ~ attached figure 2 ): attached figure 1 For the state of transmitting the maximum torque, the attached figure 2 For the state of no torque transmission or negligible torque transmission, the size of the base plate 6 is 120mm in diameter, the size of the pin 11 is 6mm, the inner diameter of the groove tube 13 is 122mm, the outer diameter is 136mm, the width of the groove 5 is 6mm, and the depth is 5mm 10 pieces of NdFeB permanent magnets are installed on Disk 14, Disk 2, Disk 9 and Disk 10, and the number can be adjusted according to the actual size. The size of the NdFeB permanent magnet is 20mm×20mm×5mm, magnet 3, magnet 8, Magnet 20 and magnet 21 are tile-shaped magnets, and width is 10mm, with image 3 For the installation position of the lever 4 in the base plate 6, the thread of the screw 16 is M8, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com