Conditioner

A conditioner and rotor technology, applied in the field of conditioners, can solve the problems of increasing equipment manufacturing and installation costs, uneven discharge, and reducing aging effects, so as to reduce equipment manufacturing and installation costs and reduce equipment occupation. Good effect of space and aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

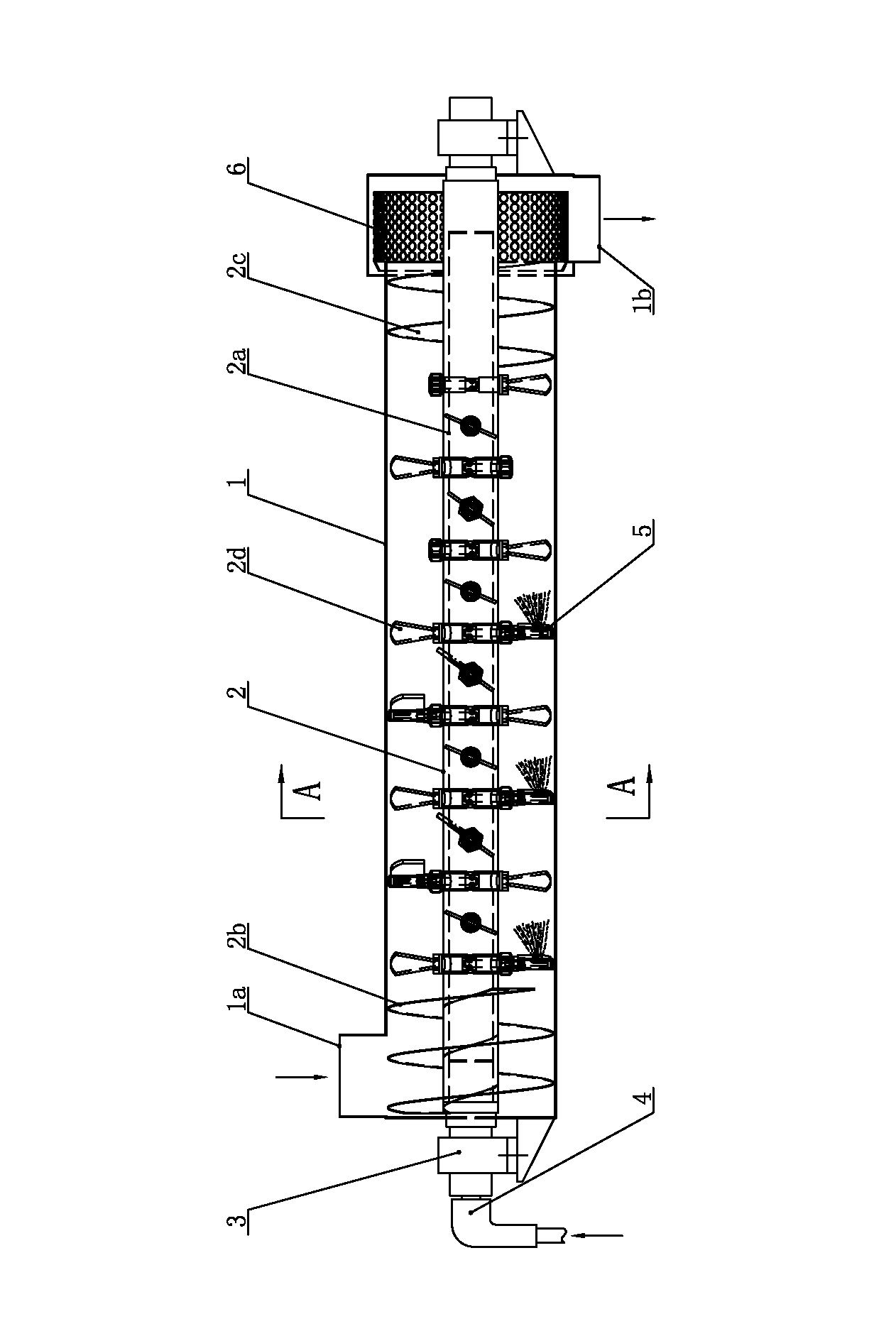

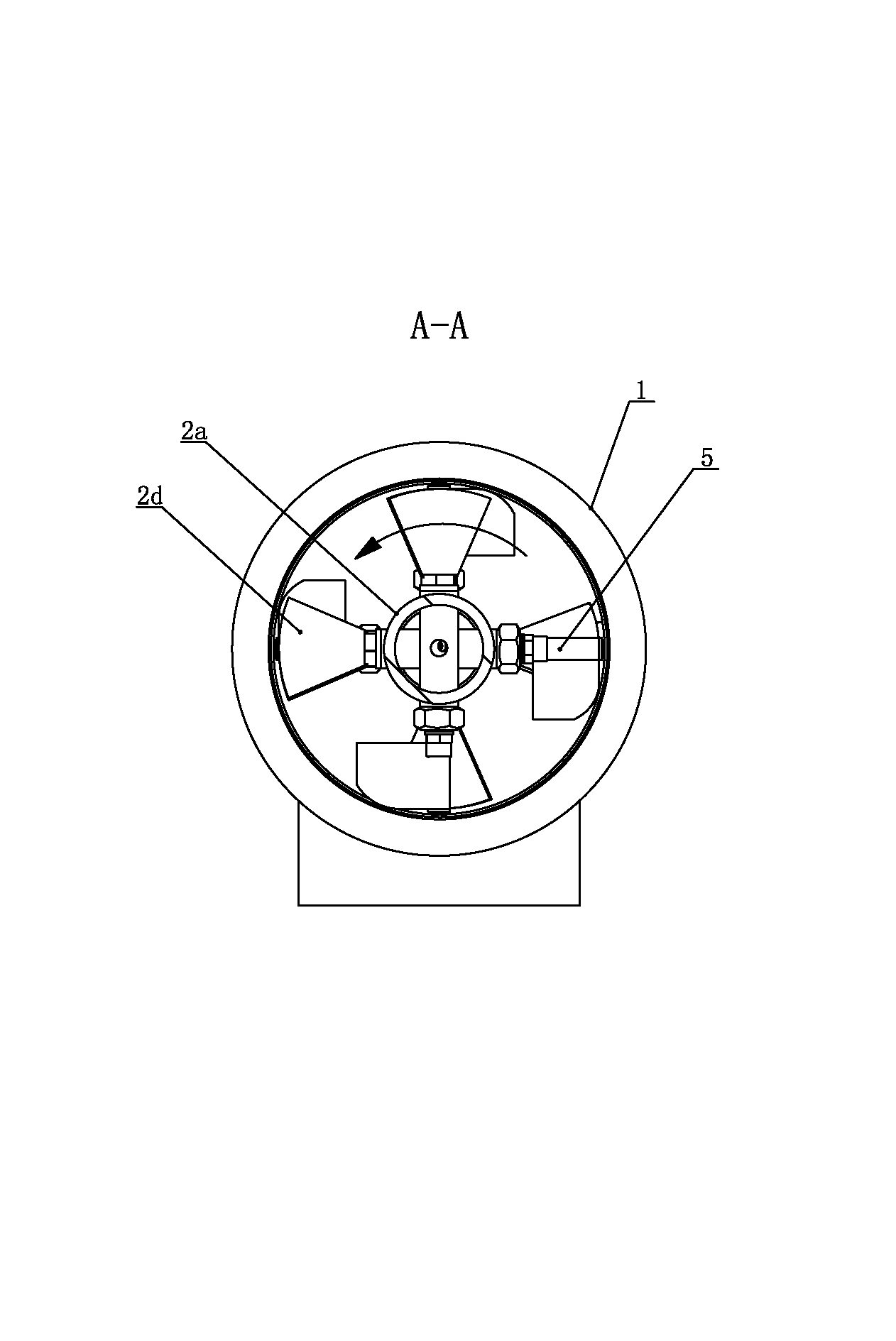

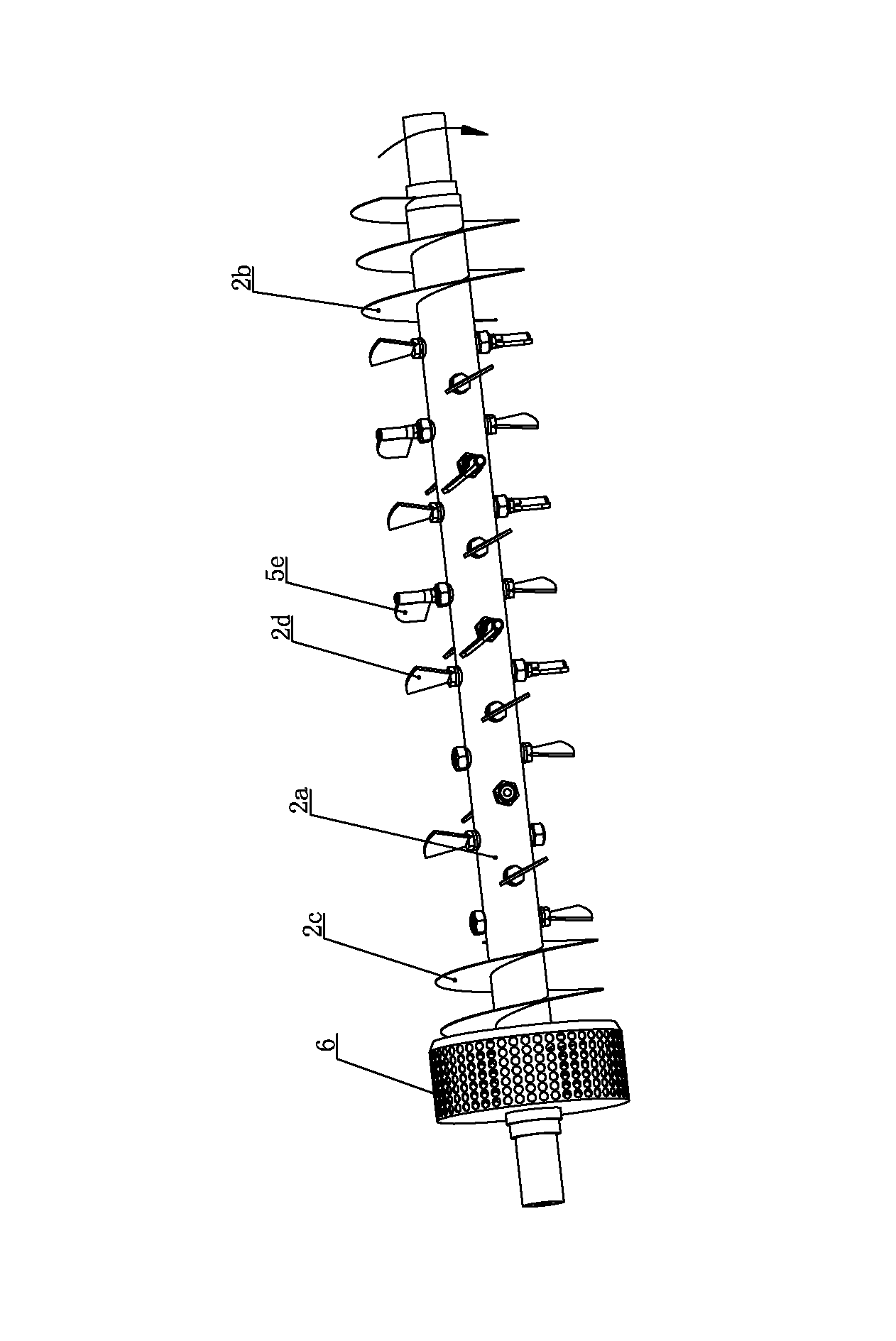

[0025] Such as Figure 1 to Figure 3 As shown, the conditioner of the present invention includes a cylinder body 1, a rotor 2 for mixing materials is installed in the cylinder body 1, and both ends of the rotor 2 are respectively supported on the machine frame through bearing seats 3. The rotor 2 includes a rotor main shaft 2a and propulsion paddles 2d evenly distributed on the rotor main shaft 2a to stir and propel materials. The upper part of one end of the cylinder 1 is provided with a feed port 1a, and the lower part of the other end of the cylinder 1 is provided with a discharge port 1b. A feed-end helical blade 2b is installed on the rotor main shaft 2a near the feed inlet, and a discharge-end helical blade 2c is installed on the rotor main shaft 2a near the discharge port. The feed-end helical blade 2b and the discharge-end helical blade 2c are both full helical structure. The rotor shaft on the outside of the spiral blade 2c at the discharge end is equipped with a uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com