Steel plate pre-treating method

A pretreatment and steel plate technology, applied in the direction of explosion generating devices, abrasives, metal processing equipment, etc., can solve the problems of high cost, low efficiency, poor pretreatment effect, etc., achieve high processing efficiency, reduce production costs, and improve pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

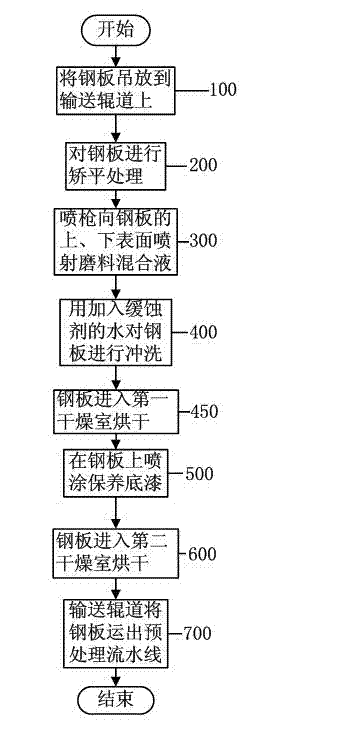

[0044] The pretreatment line includes electromagnetic crane, conveying roller table, air compressor, abrasive mixture supply device, multi-roll leveler, derusting room, flushing device, spraying room, first drying room and second drying room.

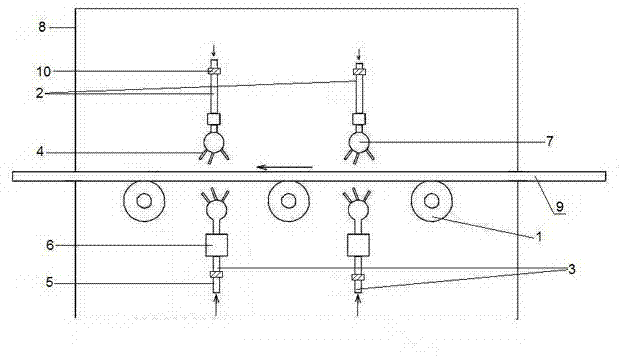

[0045] like figure 1 As shown, the conveyor roller table located in the derusting chamber includes three horizontal rollers 1 arranged at intervals. The steel plate 9 is located on horizontal rollers.

[0046] An upper spray gun array 2 is arranged above the horizontal roller, and a lower spray gun array 3 is arranged below the horizontal roller. The nozzles of the upper spray gun array are downward, and the nozzles of the lower spray gun array are upward; the nozzles of the lower spray gun array face two adjacent horizontal rollers interval position.

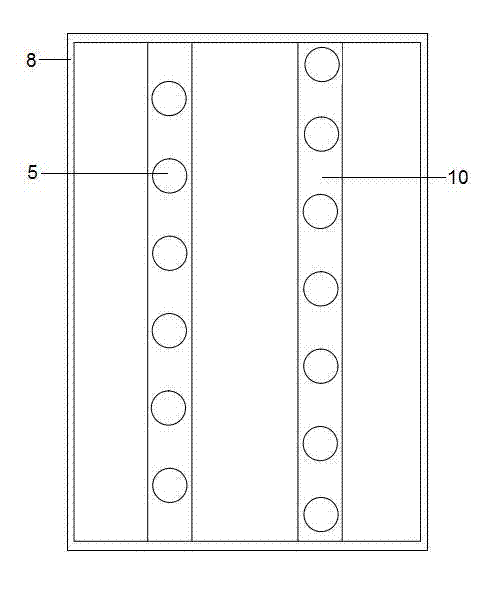

[0047] like figure 2 As shown, the upper and lower spray gun arrays both include a left spray gun column and a right spray gun column, the left spray gun column is composed of 6 spra...

Embodiment 2

[0063] Embodiment 2 includes all structural parts and step parts in Implementation 1. like Figure 4 Shown, in embodiment 2 except the step part in embodiment 1, also comprise the following steps:

[0064] Step 250, use oxyacetylene flame to spray the surface of the flattened steel plate. The surface temperature of the burned steel plate reaches 40 degrees.

[0065] After the surface of the steel plate with heavy oil stains and stains is cleaned by flame combustion, the subsequent derusting treatment is carried out to ensure the pretreatment effect of the steel plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com