Blue leather separator

A technology of blue leather and sorting system, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of low work efficiency, high labor intensity, increase leather manufacturing cost, etc., to reduce labor intensity, compact equipment structure, blue Smooth skin transition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

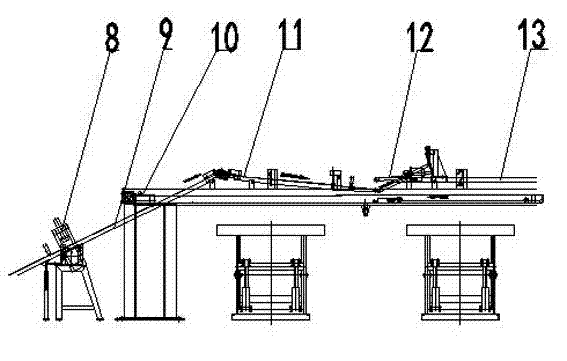

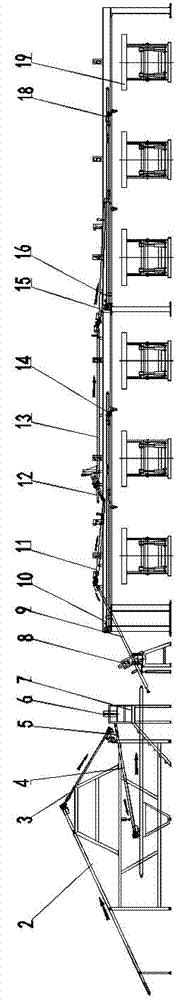

[0021] Depend on figure 1 From the schematic diagram shown, it can be seen that the blue skin sorting system of the present invention mainly includes a grading mechanism for manually grading the passing blue skins, and a palletizing mechanism for placing the blue skin codes in corresponding positions according to the classification results.

[0022] The grading mechanism mainly includes a grading conveyor belt group that allows blue skins to pass through, and a grading operation platform 7 located on one side of the grading conveyor belt group for carrying operators. The grading operation platform 7 is provided with a grading control panel for the operator to input the grading results 6. The grading conveyor belt group includes the leather-laying conveyor belt 2 and the leather-inspecting conveyor belt 3 arranged in sequence. The leather-laying conveyor belt 2 and the leather-inspecting conveyor belt 3 form a "herringbone" shape, and the grading operation level 7 is located on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com