Mould for casting concrete foundation

A technology for pouring concrete and molds, which is applied in infrastructure engineering, construction, etc., can solve the problems of easily polluted concrete, easily bonded concrete, time-consuming and laborious installation, etc., and achieves the effects of reducing environmental pollution, strong plasticity, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

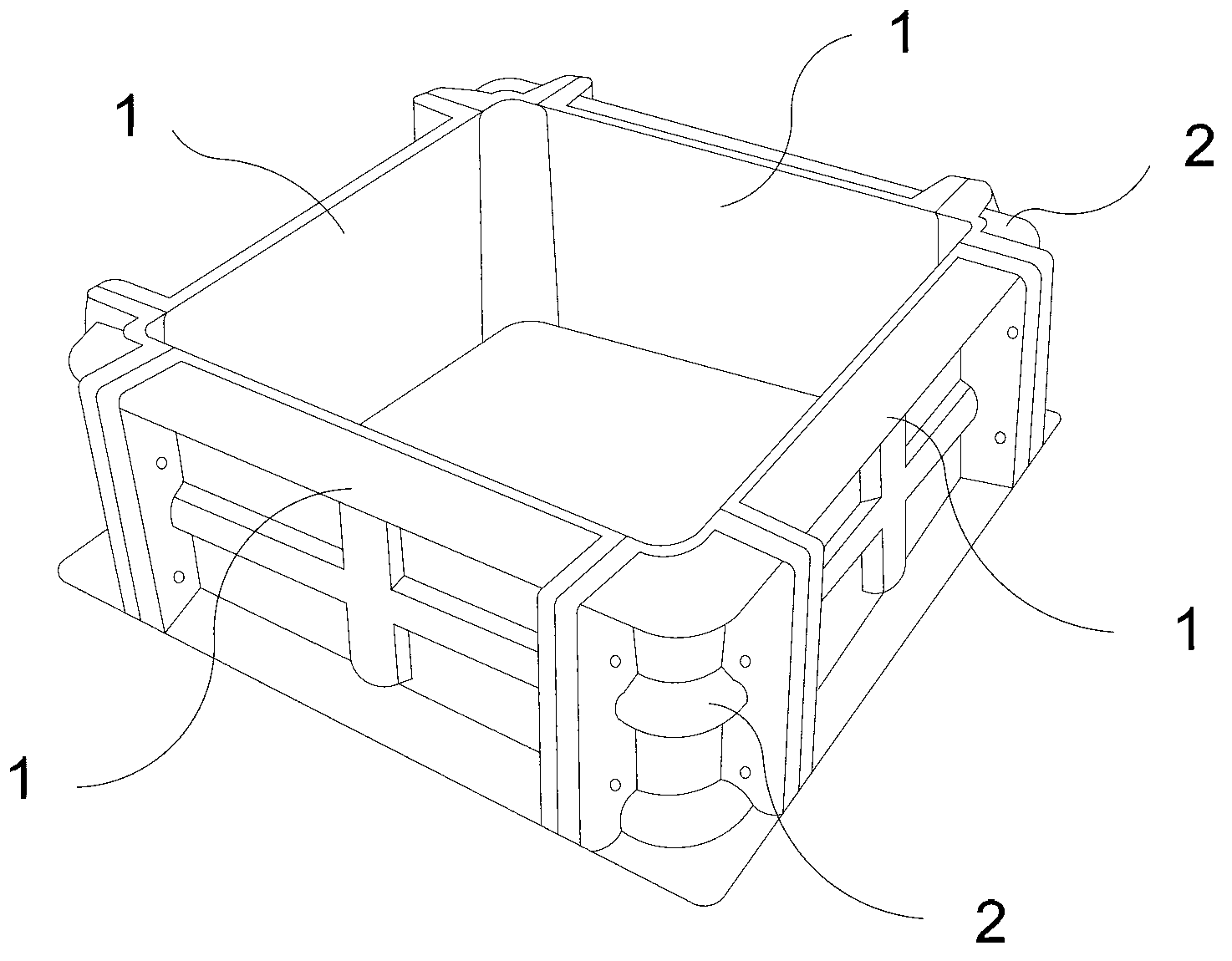

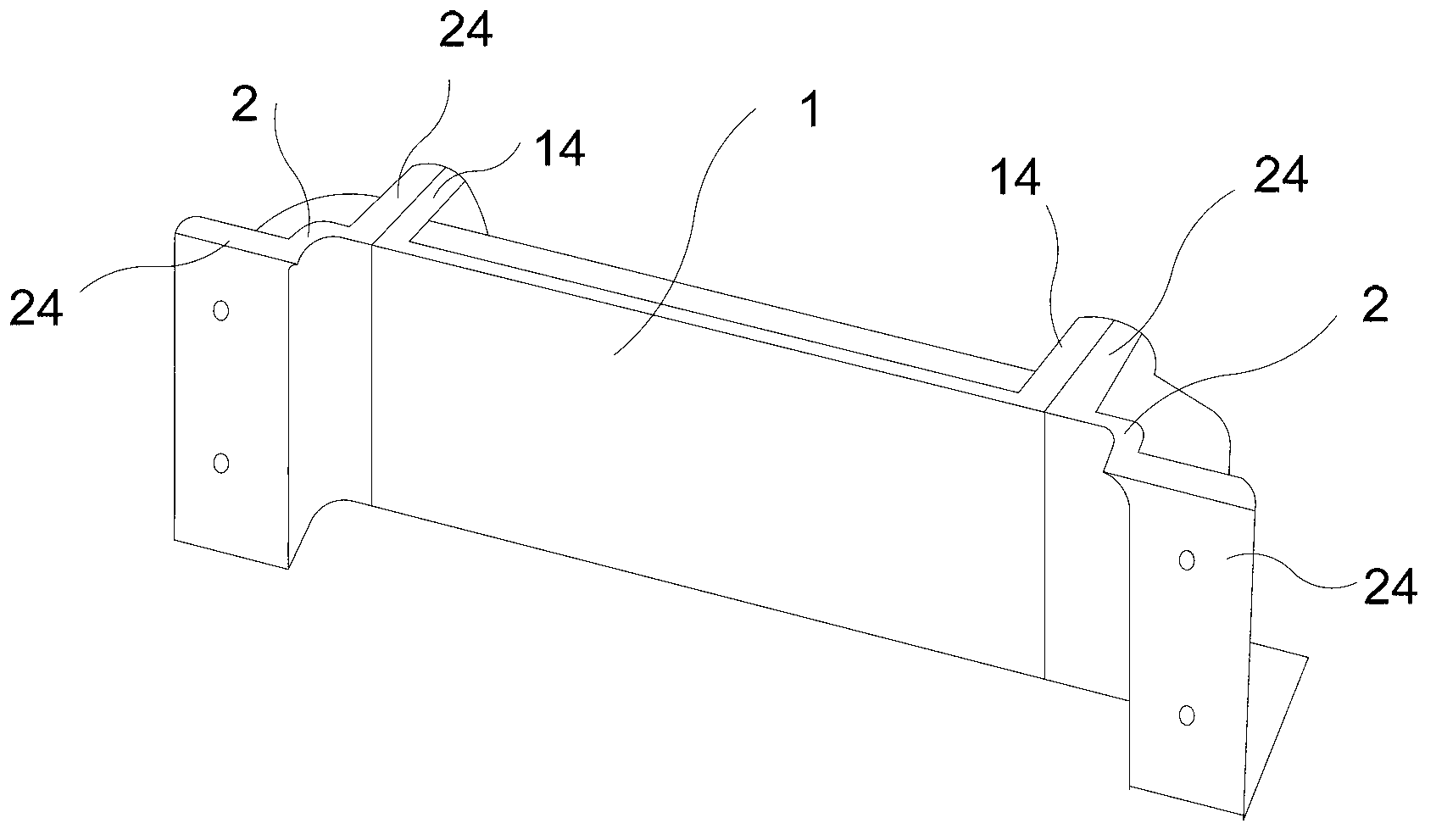

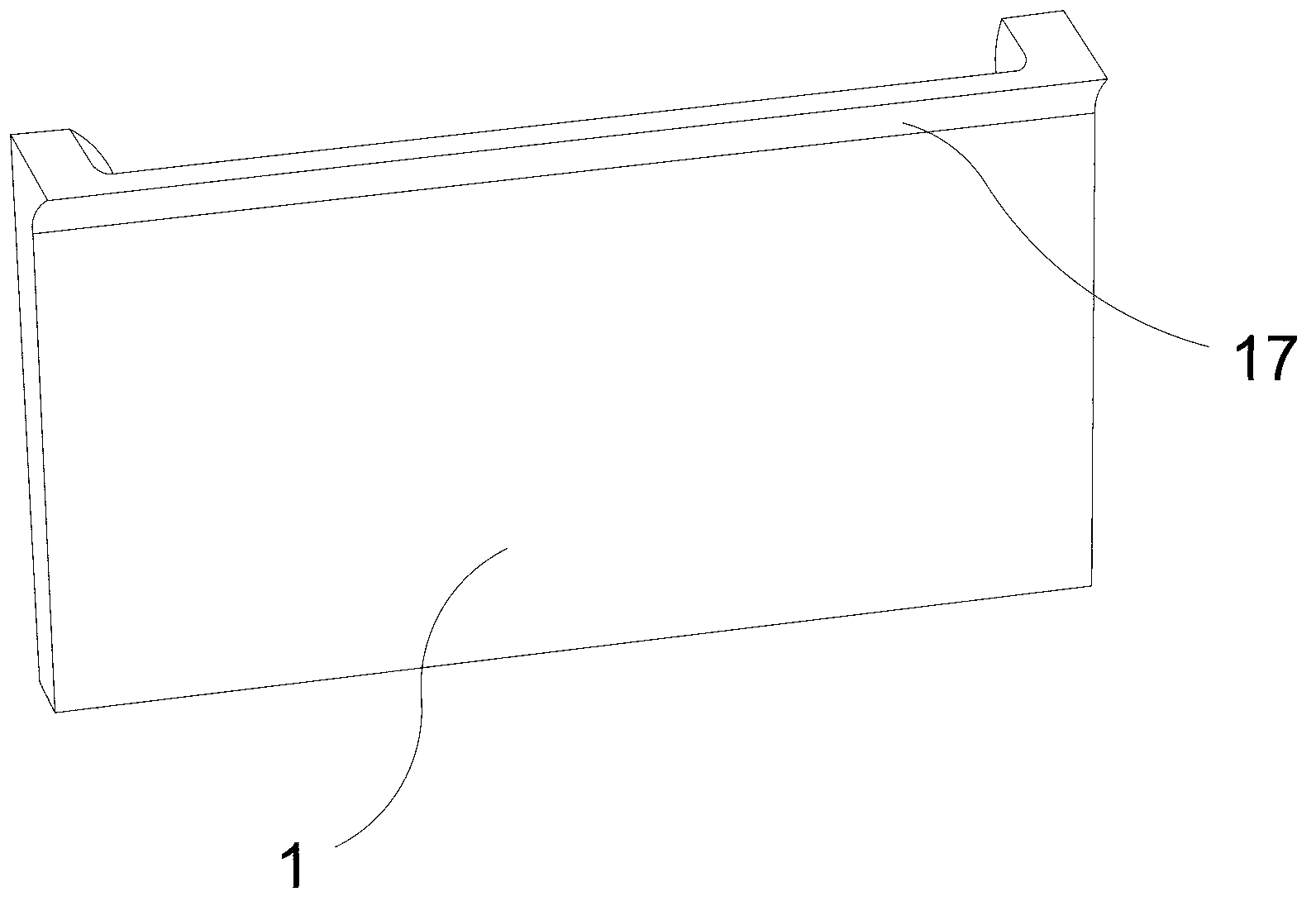

[0028] Such as Figure 1-Figure 5 As shown, the mold of the pouring concrete foundation of the present embodiment is a square, including four side plates 1 of the same length used to surround a square frame all made of glass fiber reinforced plastics and used to connect adjacent side plates 1 of the four corner panels 2 . Such as figure 2 As shown, the inner surface of the side plate 1 is a smooth plane, and the inner surface of the corner plate 2 is a smooth arc surface with a smooth transition with the side plate 1; the two ends of the side plate 1 are provided with a first connection protruding outward 14, the two ends of the gusset 2 are provided with a second connecting portion 24 protruding outward. When assembled into a formwork, the ends of the side panels 1 and the corner panels 2 are fitted together, and the insides thereof transition smoothly without gaps. Compared with the wooden or steel molds used in the prior art, the mold made of fiberglass material in this...

Embodiment 2

[0038] Such as Figure 6 As shown, the second connecting portion 24 of the corner plate 2 is provided with a positioning groove 21 on the surface that is used to fit the first connecting portion of the other side plate (not shown in the figure), and the other side plate that is in contact with it The side of the first connecting part of the side plate is provided with matching positioning strips (not shown in the figure), so as to realize rapid assembly, make the corner plate 2 and the side plate 1 neatly docked, and improve the surface of the formed concrete foundation Quality, to avoid unnecessary vertical bars due to the loose engagement of the corner plate 2 and the side plate 1.

[0039] Such as figure 2 and Figure 6 As shown, in Embodiment 1 and Embodiment 2, the attached surface of the side plate 1 and the connected corner plate 2 extends from its end to its connecting portion, so that when the two are connected, the connecting portion It is also directly attached,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com