Emission control system for internal combustion engine

An emission control system, a technology for an internal combustion engine, applied in the directions of engine control, fuel injection control, electrical control, etc., can solve problems such as deterioration of exhaust gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example )

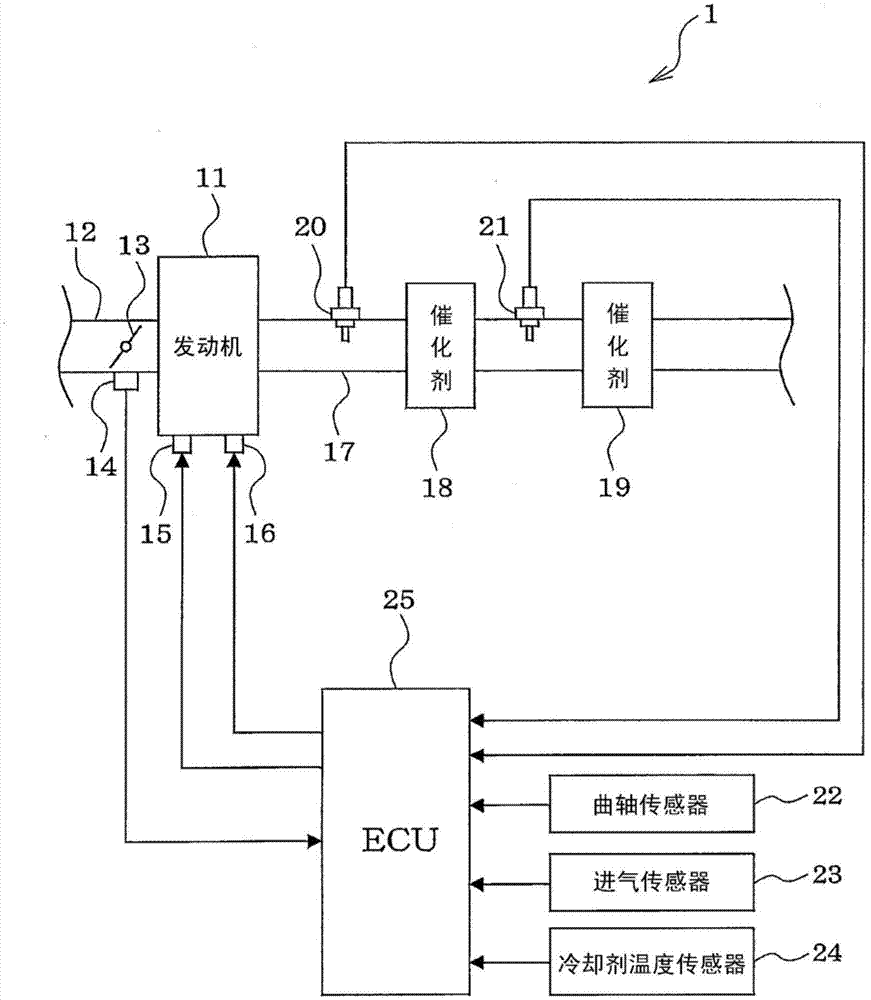

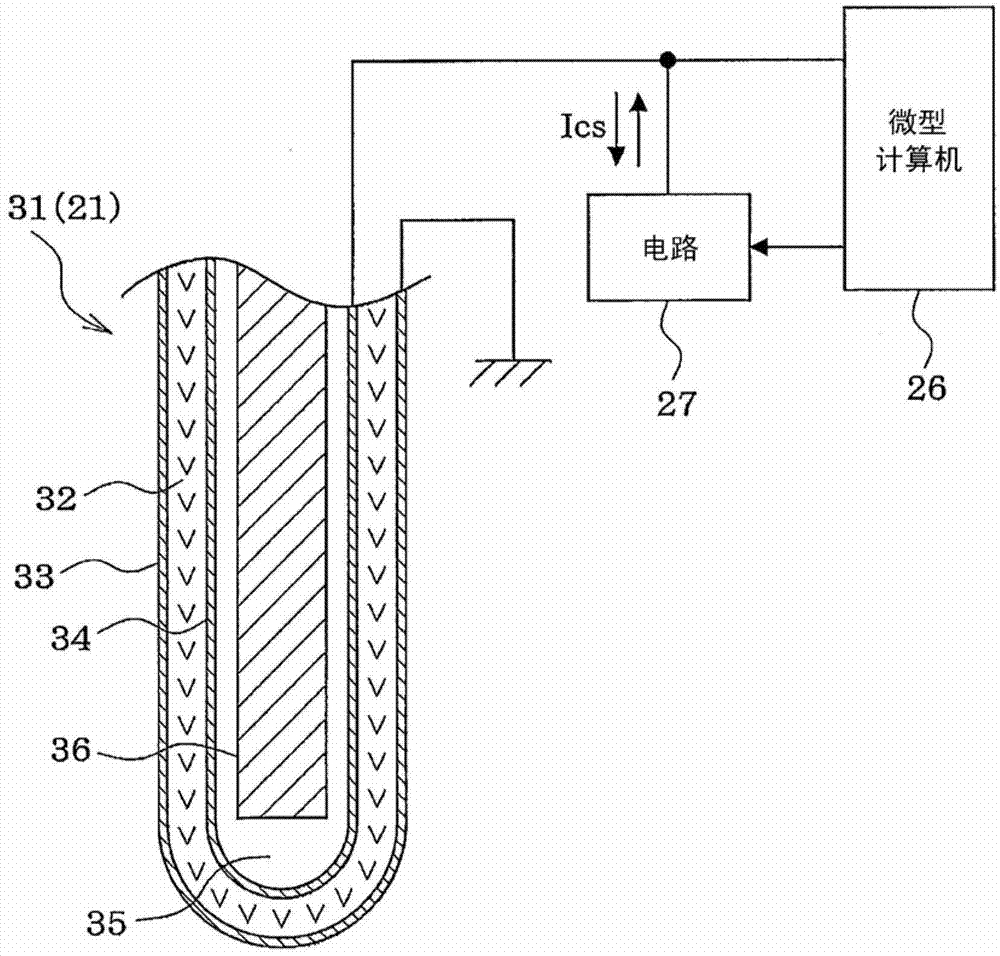

[0029] will refer to Figure 1 to Figure 9 A first embodiment of the present disclosure will be described. First, based on figure 1 The emission control system 1 of the present embodiment is described.

[0030] The emission control system 1 includes an engine 11 (internal combustion engine), an intake pipe 12 through which intake air flows and is drawn into the engine 11 , a throttle valve 13 provided in the intake pipe 12 , and a throttle sensor 14 provided in the intake pipe 12 . The throttle sensor 14 detects the throttle opening of the throttle valve 13 by adjusting the opening (throttle opening) of the throttle valve 13 using a motor or the like. The engine 11 includes fuel injection valves 15 respectively attached to cylinders of the engine 11 to inject fuel into the cylinders or into intake portions of the cylinders, and spark plugs 16 respectively disposed adjacent to the cylinders of the engine 11. cylinder head. Spark plug 16 creates an electrical spark to ignite...

no. 2 example )

[0074] will refer to Figure 10 The second embodiment will be described. Explanation of parts in the second embodiment that are substantially the same as those in the first embodiment will be omitted or simplified, and parts in the second embodiment that are different from the first embodiment will be mainly described.

[0075] In the first embodiment, when the execution condition of the rich direction control (rich direction condition) is satisfied during the fueling stop control, the rich RSP control is started. In the second embodiment, ECU25 (or microcomputer 26) executes Figure 10 The routine for emission reduction control is shown, and rich RSP control is started early after rich directional control is started.

[0076] exist Figure 10 In the routine of the emission reduction control shown in , it is first determined in step 201 whether or not the refueling stop control is executed. When it is determined in step 201 that the fueling stop control is to be executed, ...

no. 3 example )

[0082] will refer to Figures 11 to 13 A third embodiment will be described. Explanation of parts in the third embodiment that are substantially the same as those in the first embodiment will be omitted or simplified, and in the third embodiment, parts that are different from the first embodiment will be mainly explained.

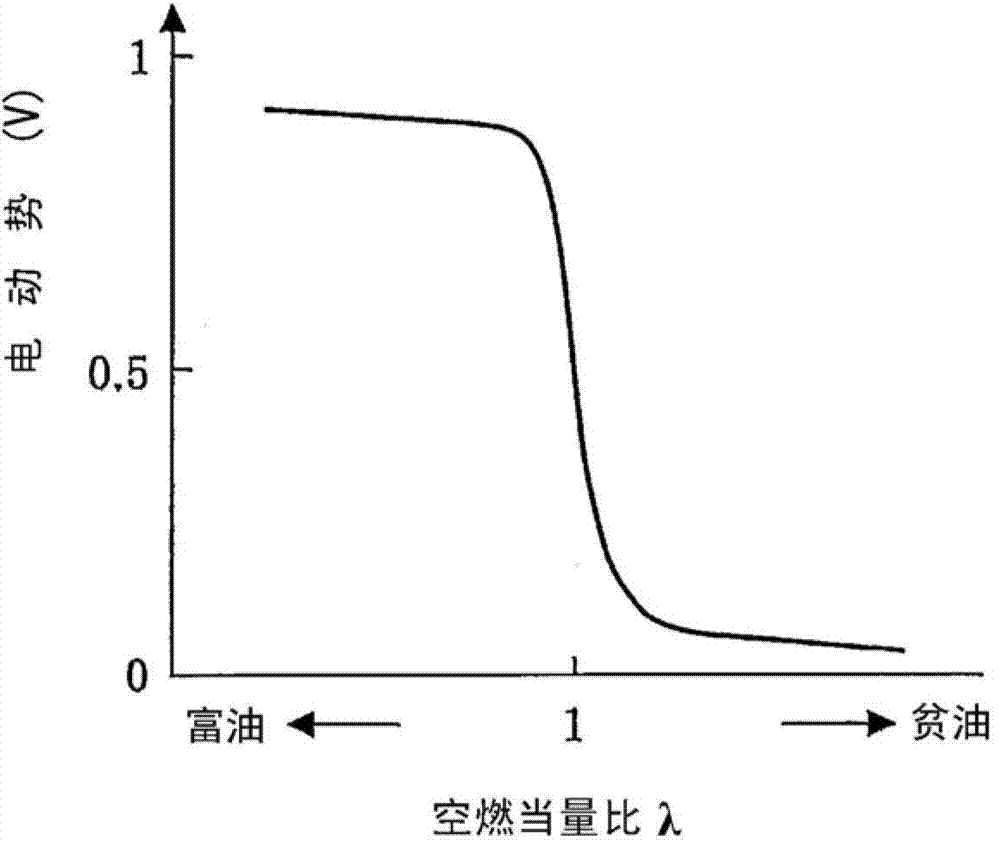

[0083] In the first embodiment, the rich direction control is terminated when the output of the oxygen sensor 21 exceeds the predetermined rich threshold value after the start of the rich direction control. In the third embodiment, the ECU 25 (or microcomputer 26) of the emission control system 1 executes Figure 13 The routine of the emission reduction control shown in , and when the estimated amount of oxygen stored in the upstream catalyst 18 (estimated stored oxygen amount) becomes equal to a predetermined reference threshold (ref.threshold), the rich direction control is terminated.

[0084] Specifically, as Figure 11 As shown, the fueling stop con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com