Jet-type crude oil and associated gas pressurizing mixing transportation process and device

An associated gas and jet-type technology, which is applied in gas/liquid distribution and storage, pipeline systems, mechanical equipment, etc., can solve problems such as environmental pollution, resource waste, and uneconomical gas pipelines, and achieve good mixed transportation effects and reduce Maintenance cost and the effect of improving resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

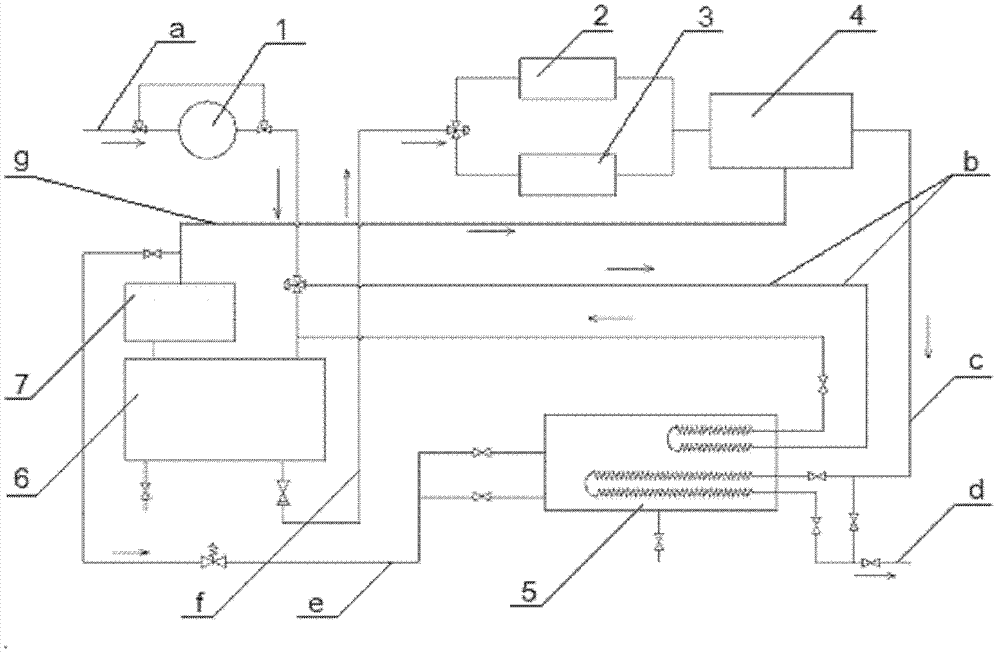

[0013] Embodiments of the present invention are further described with reference to the accompanying drawings:

[0014] The process steps of jet-type crude oil and associated gas pressurized mixed transportation are as follows:

[0015] (1). After the incoming oil is filtered by the filter 1 and heated by the heating furnace 5, it is input into the buffer tank 6 (or according to the working conditions, the future oil is directly input into the buffer tank 6 without heating), and the associated gas in the incoming oil is separated;

[0016] (2). The separated associated gas is input into the associated gas separation tank 7, and the separated crude oil is input into mixing pumps 2 and 3 for boosting;

[0017] (3). Pump most of the separated associated gas into the jet pump 4 to mix with the pressurized crude oil, and transport it outside after heating (or according to the working conditions, directly transport the pressurized mixed oil and gas without heating ).

[0018] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com