Waste heat recovery system for deaerator and power plant power generation system

A power generation system and deaerator technology, applied in chemical instruments and methods, preheating, steam generation, etc., can solve problems such as unfavorable power plant production targets, energy waste, etc., and achieve the goals of saving raw materials, improving ambient temperature, and avoiding energy waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

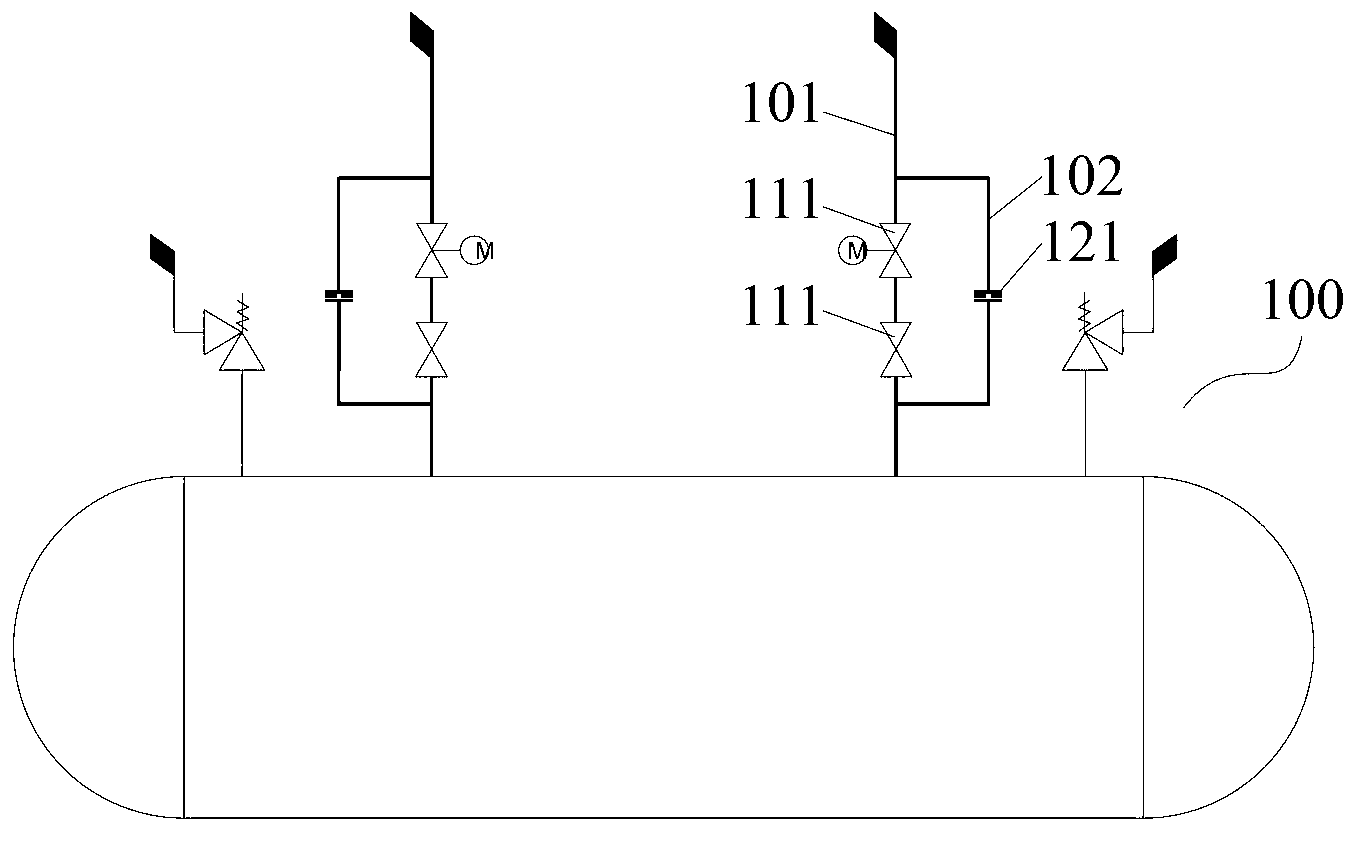

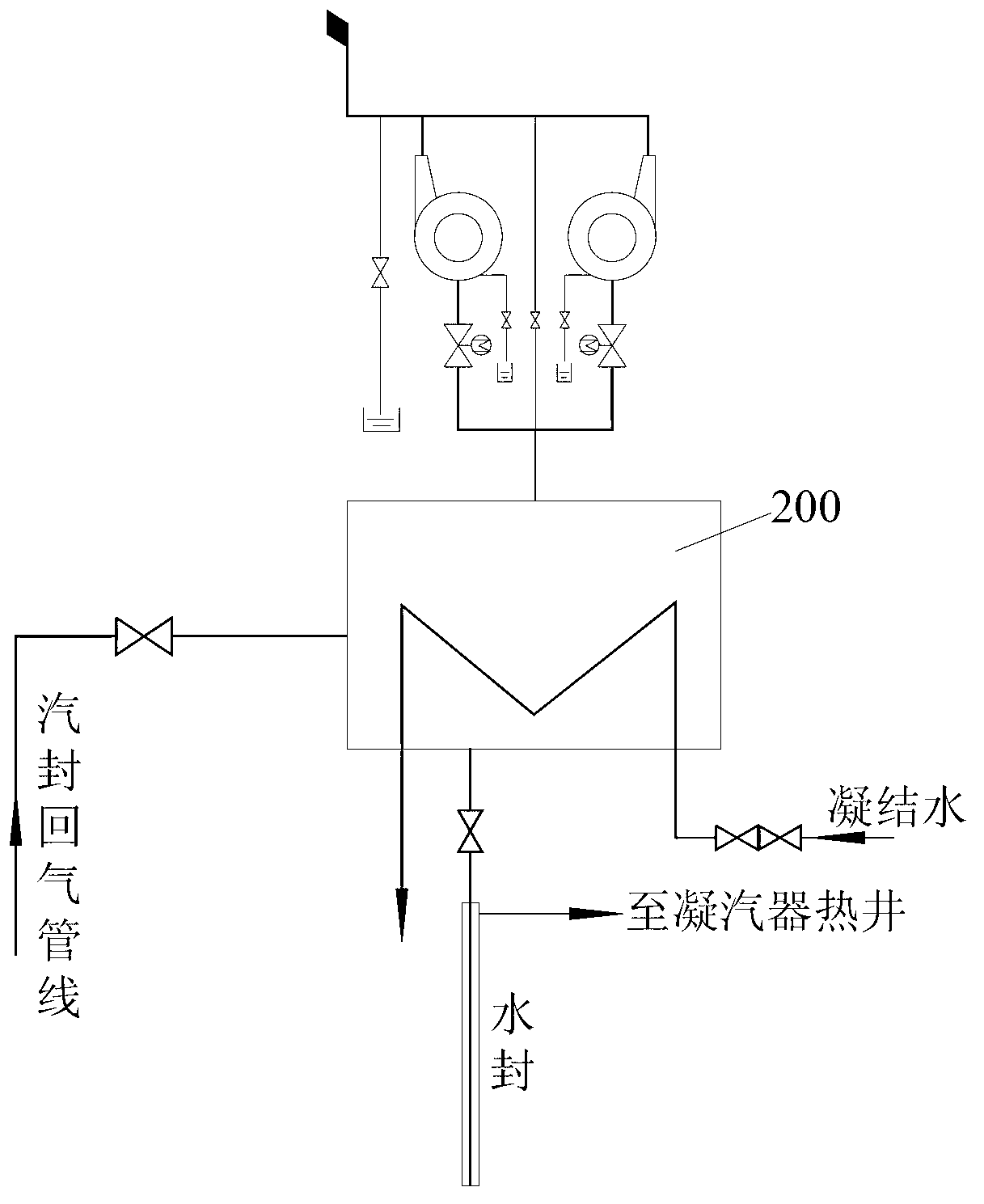

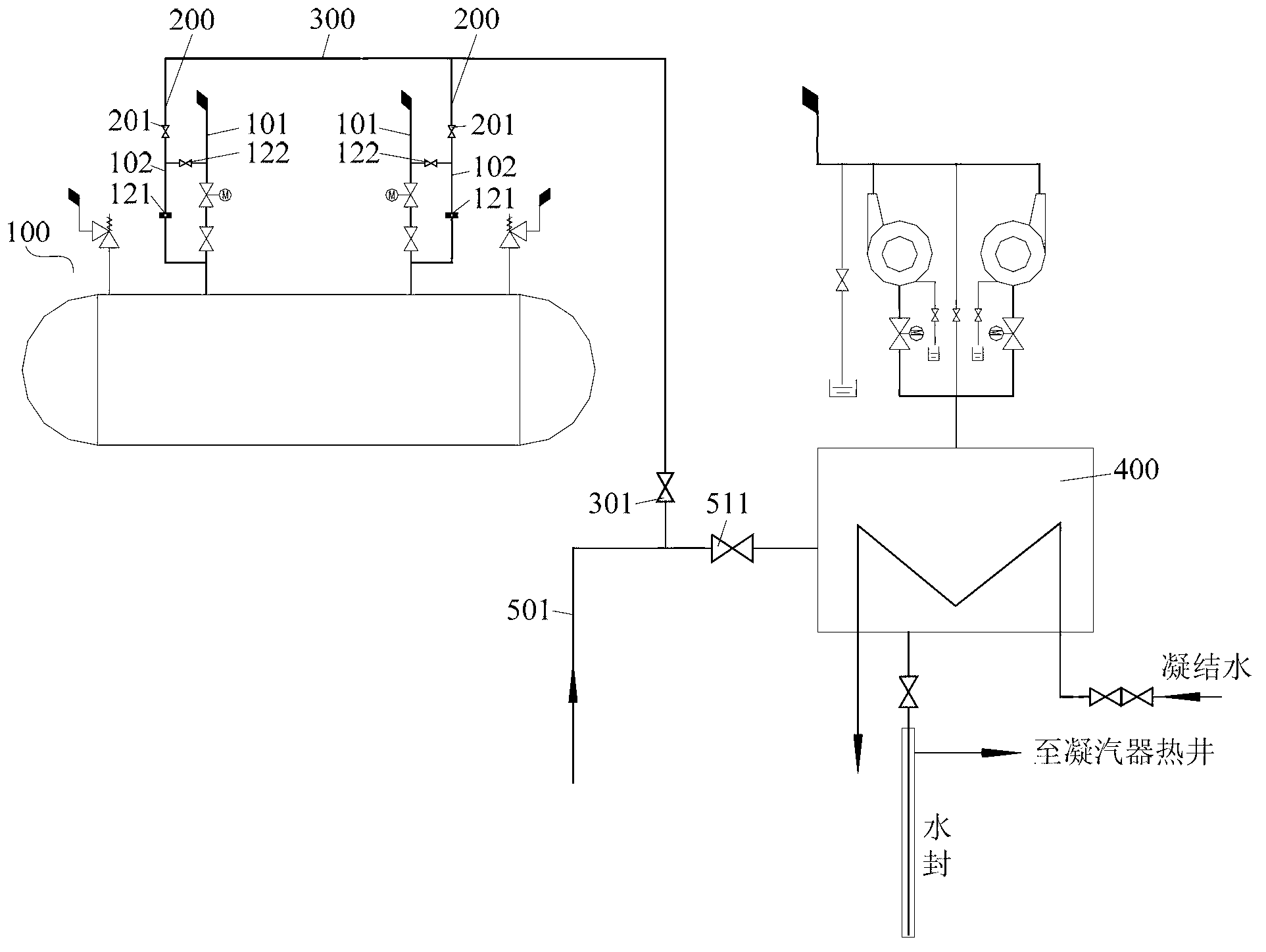

[0030] The embodiment of the invention discloses a waste heat utilization system for a deaerator, which can make full use of the waste heat of the exhausted steam of the deaerator, avoid waste heat waste, and realize energy saving and emission reduction. The embodiment of the present invention also discloses a power generation system of a power plant, which applies the above-mentioned waste heat utilization system, which can avoid waste of exhaust steam waste heat of a deaerator in the system, and can realize energy saving and emission reduction.

[0031] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of or...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap