Thermal expansion valve and assembling method

A thermal expansion valve and valve body technology, applied in lighting and heating equipment, refrigerators, fluid circulation arrangements, etc., can solve the problems of many parts, hidden dangers of leakage, increased management costs and assembly processes, etc., to improve overall performance, The effect of reducing the risk of leakage and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings.

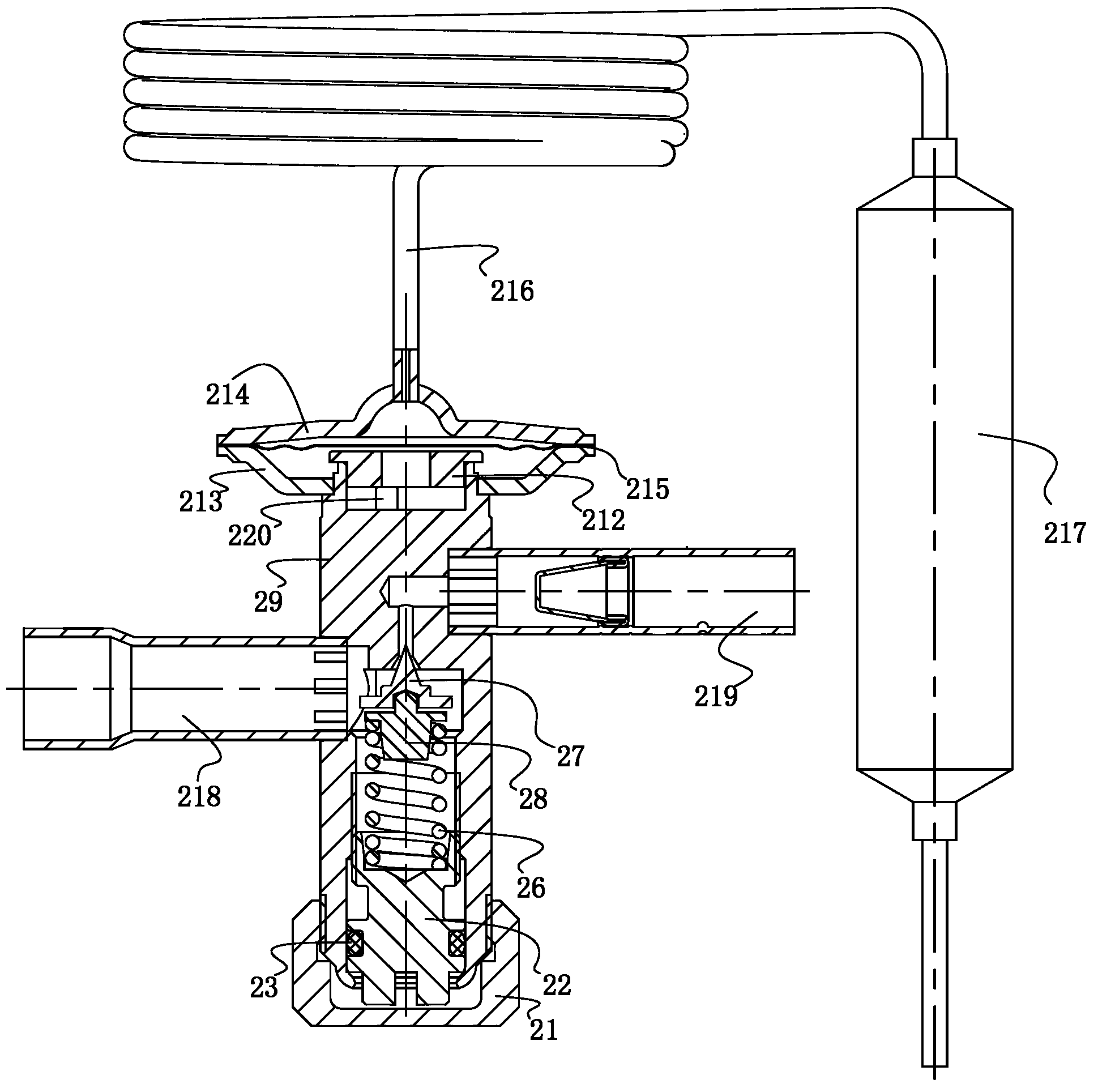

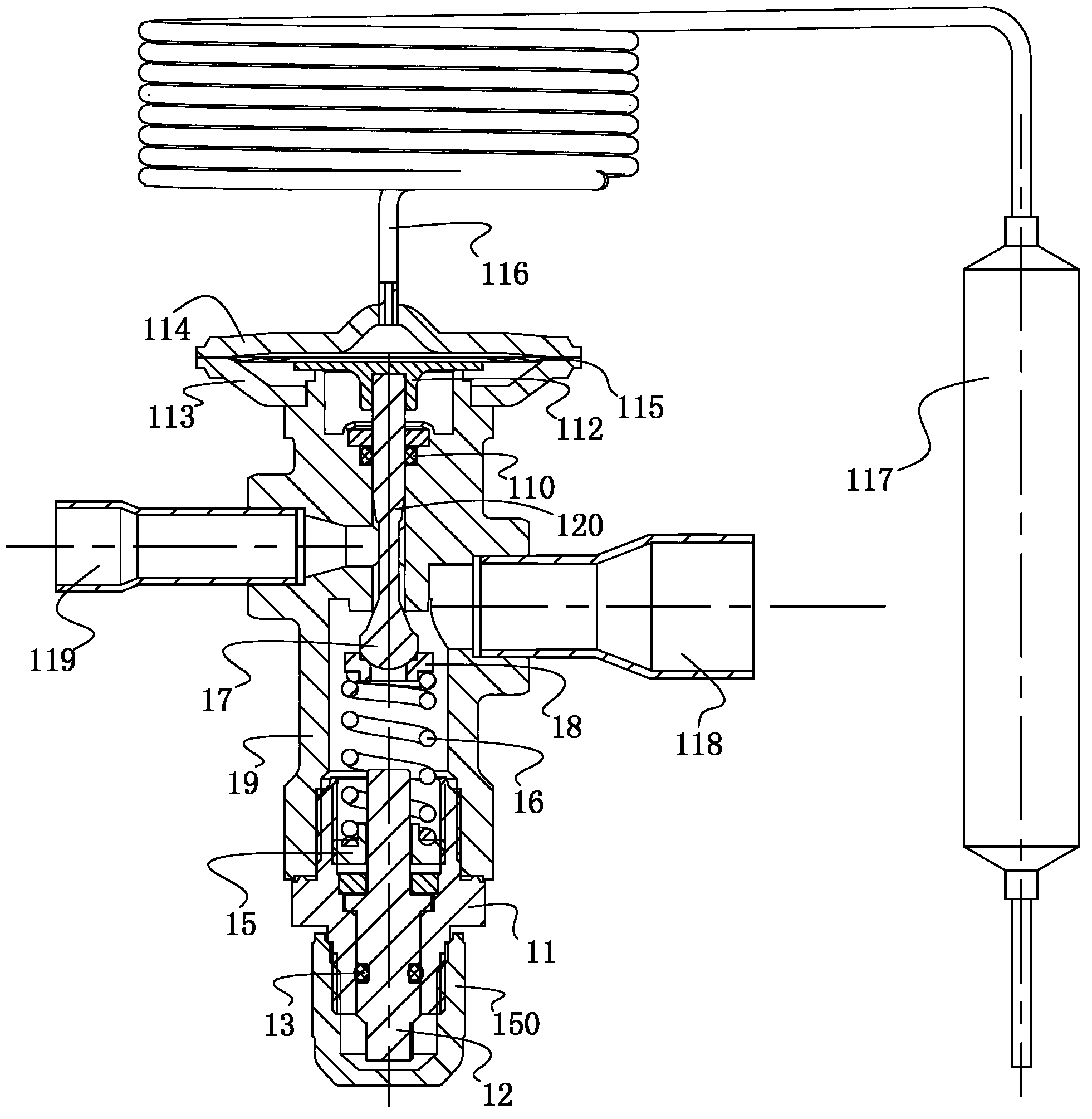

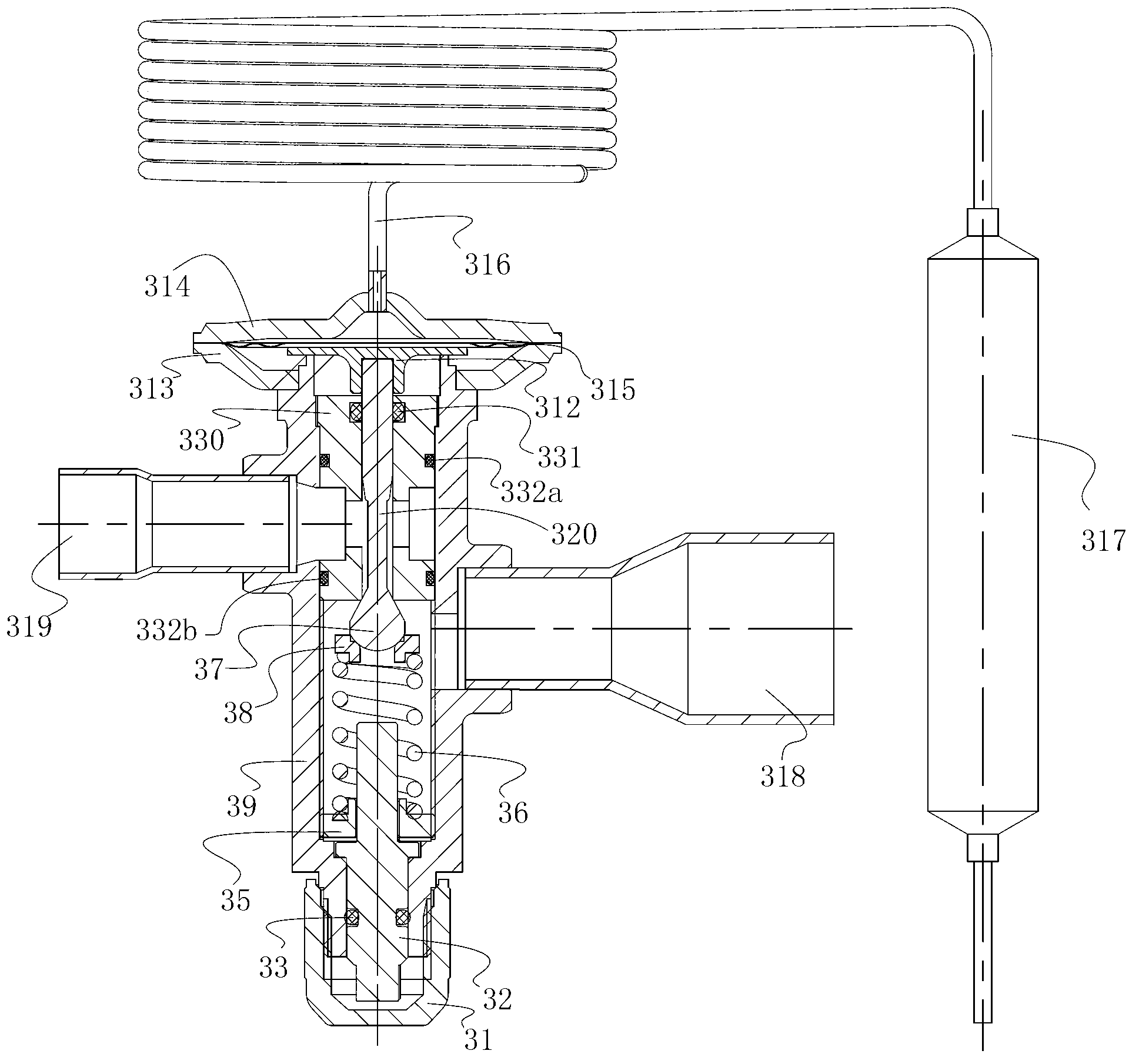

[0040] like image 3 As shown, the thermal expansion valve of the present invention includes a valve body 39, an air box head connected to the upper end of the valve body 39, a valve core assembly and an adjustment assembly, and the adjustment assembly includes such as Figure 5 The adjustment rod 32 shown is matched with the matching part 321 on the upper part of the adjustment rod 32 and can slide relative to the adjustment rod 32 in the axial direction of the adjustment rod 32 but cannot rotate relative to the spring seat 35 of the adjustment rod, which is used to support the valve core 37 The spool support seat 38 and the adjustment spring 36 sandwiched between the spool support seat 38 and the spring seat 35 ; the spool assembly includes a transmission rod 320 and a spool 37 . Adjusting rod 32 comprises three parts, and its lower end is regulating part 322, and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com