Electroosmosis-vacuum-loading combined consolidometer

A consolidation instrument and vacuum technology, applied in the field of geotechnical engineering, can solve problems such as complex structure, unsuitable for popularization and application, and inability to ensure vertical constant pressure applied to soil samples.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Further description below in conjunction with accompanying drawings.

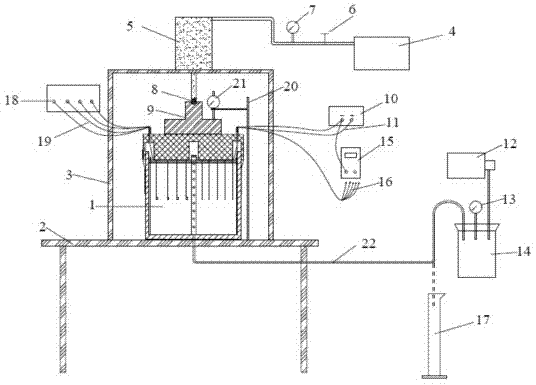

[0019] Such as figure 1 As shown, the combined electroosmosis-vacuum-loading consolidation instrument includes a consolidation container 1, a DC power supply 10, a loading system, a vacuum system and a measuring system. The loading system adopts cylinder loading, including test bench 2, loading frame 3, loading cylinder 5, air compressor 4, pressure reducing valve 6, pressure gauge 7, loading steel ball 8 and loading pad 9. The DC power supply 5 is connected to the cathode drainage pipe 26 and the anode 27 respectively through wires and wire conduits. Vacuum system is made up of vacuum pump 12, steam-water separator bottle 14 and vacuum gauge 13. The measurement system includes a pore pressure sensor 28 , a pore pressure display 18 , a potential measuring probe 29 , a multimeter 15 , a dial gauge 21 and a graduated cylinder 17 .

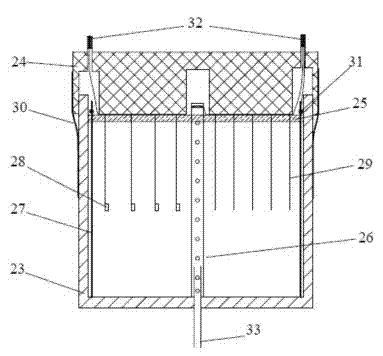

[0020] Such as figure 2 As shown, the consolidation container 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com