Pluggable planar optical waveguide device and manufacturing method thereof

A planar optical waveguide and pluggable technology, which is applied in the field of pluggable planar optical waveguide devices and its production, can solve the problems of many turnover links, difficulties in use and operation, and damage to optical fibers, so as to reduce production links and reduce Production cost, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

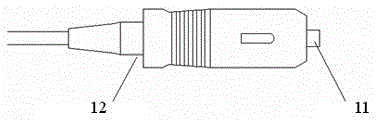

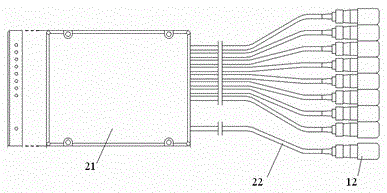

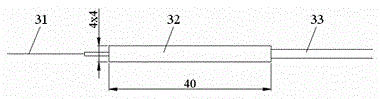

[0043] In this embodiment, the planar optical waveguide chip 100 adopts a planar optical waveguide splitter chip with single-channel input and eight-channel output, which has one input waveguide and eight output waveguides, and the two end faces are processed into 8 degrees; its input end is connected to The fiber optic assembly 300 uses Figure 10The single-channel fiber optic array 301 shown; its output is connected to Figure 11 An eight-lane connection ferrule 201 is shown.

[0044] The single-channel optical fiber array 301 has an optical fiber, which is placed and fixed in the V-shaped groove of the optical fiber array with an adhesive, and the end face is processed to be 8 degrees to be precisely connected with the input waveguide of the planar optical waveguide optical power splitter chip; the other A certain length of optical fiber 400 can be reserved on the side according to application requirements, and a conventional single-channel connector can be added to the en...

Embodiment 2

[0049] In this embodiment, the overall structure of the pluggable planar optical waveguide device is similar to Embodiment 1, the only difference is that the optical fiber assembly uses a single-channel connection ferrule 302, such as Figure 14 shown.

[0050] One end face of the single-channel connection ferrule 302 is processed at 8 degrees, and its optical fiber is precisely connected to the waveguide; the other end face can be processed as a plane or an inclined plane, and has a guide pin 700 or a jack as a connector to ensure that the plugging application Precision alignment between the fibers in the splicing ferrule and the fibers in the customer end connector. The client's connector can be a regular single-channel connector.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com