Exposure device and exposure method

一种曝光装置、光干涉的技术,应用在照相制版工艺曝光装置、微光刻曝光设备、光学等方向,能够解决影响曝光装置精度使用的便捷、校准过程复杂等问题,达到减小干扰、提高产量、提高效率和产量的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

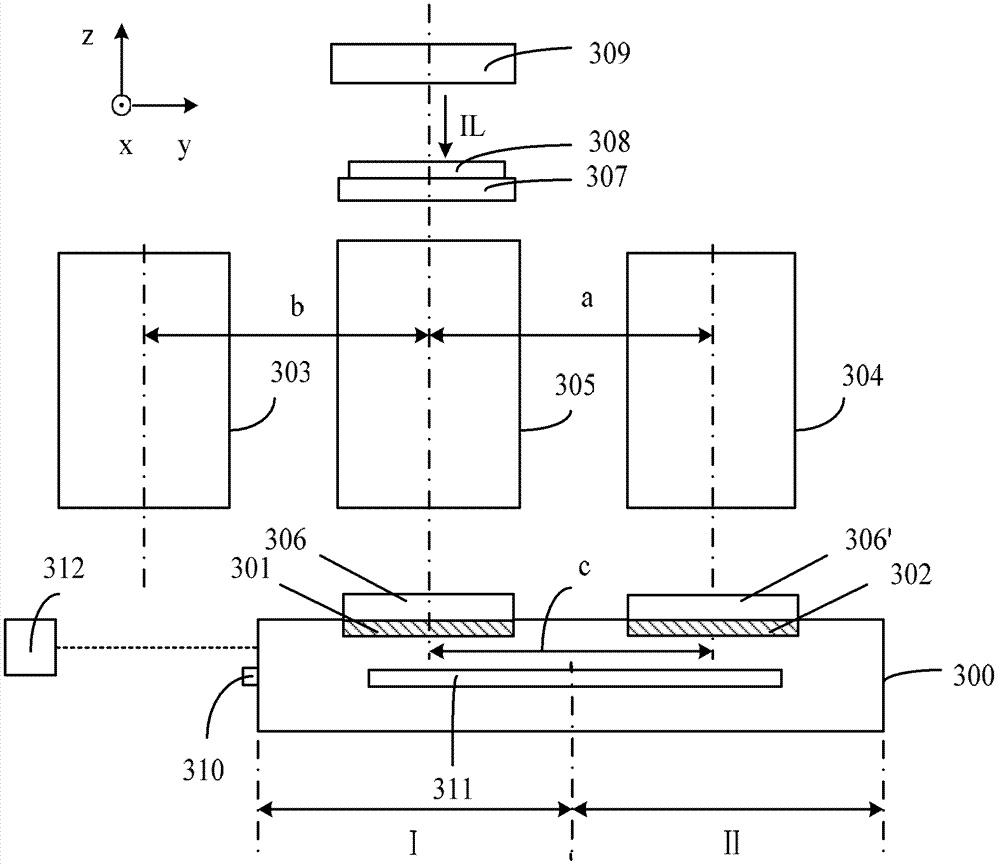

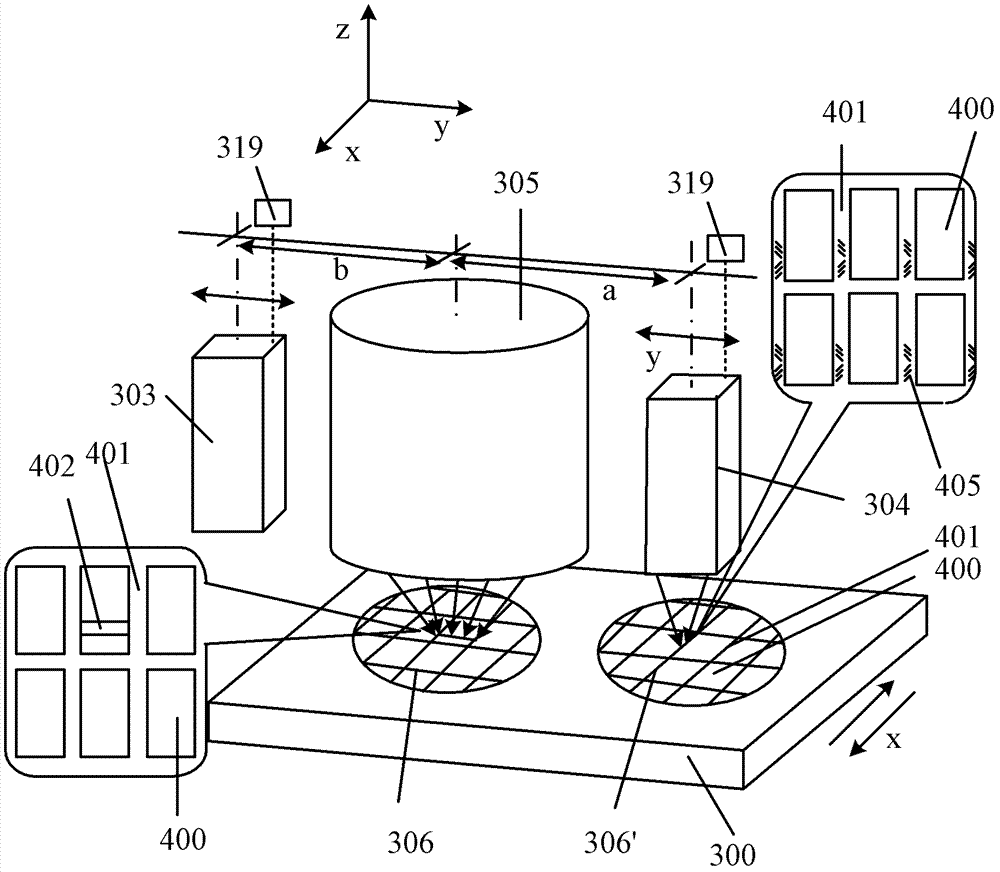

[0055] In the existing dual-stage exposure device, the calibration between the two measurement units of the two stages is complex and difficult, and disturbances are easily generated between the four optical interferometers, making it difficult to accurately position the two stages, affecting the output of the exposure device.

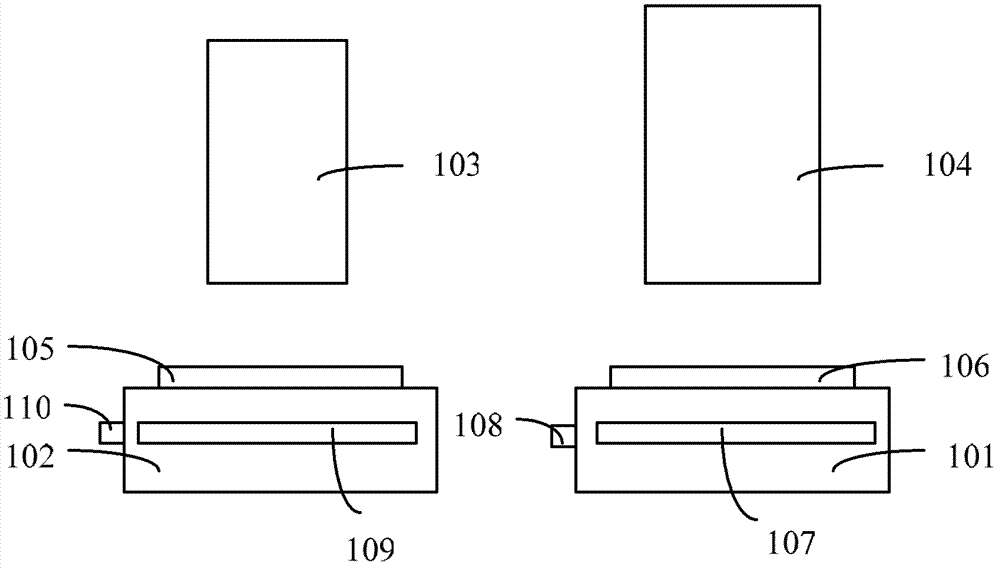

[0056] In order to solve the above problems, the inventor proposes an exposure device, including: a stage, the stage includes a first area and a second area corresponding to the first area, and the stage also includes A first substrate holder and a second substrate holder located in the second region;

[0057] an optical projection unit, located above the stage, for exposing the substrate on the first substrate holder or the second substrate holder;

[0058] The first alignment detection unit and the second alignment detection unit, the first alignment detection unit and the second alignment detection unit are symmetrically distributed on both sides o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com