Numerical simulation method for P92 steel tube welding heat affected zone

A welding heat-affected zone and numerical simulation technology, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as affecting high temperature performance, reducing material toughness, and performance component differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical scheme of the present invention will be further described below in conjunction with specific examples. In order to achieve the above-mentioned purpose of the invention, the simulation of the welding temperature field between P92 and S30432 should be carried out at first, and then the analysis should be carried out according to the simulation results to find out the width of the heat-affected zone at the end of P92. The relationship between the distribution and welding current.

[0026] The analysis process mainly includes the following steps:

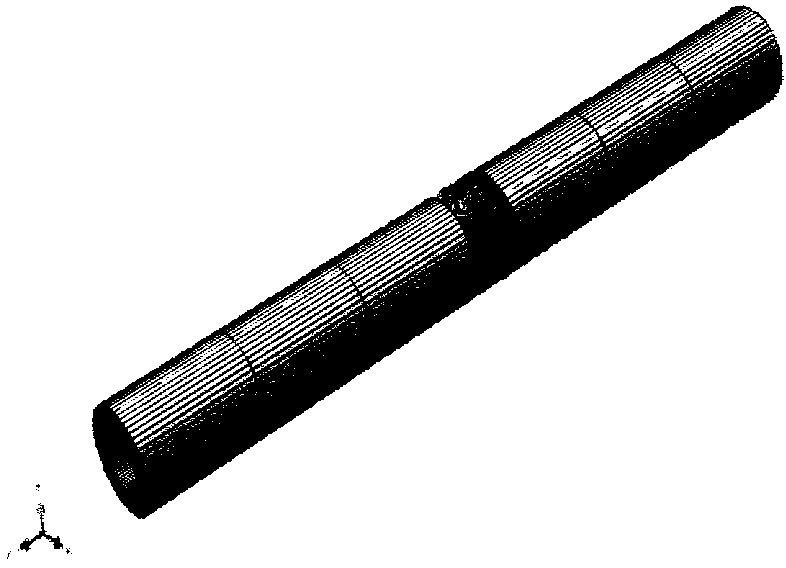

[0027] (1) Establish a welding model and assign material thermophysical coefficients: the length of the model is 200mm, the wall thickness is 10mm, the outer diameter is 45mm, the weld seam is V-shaped groove, and the groove angle is 70°. After completing the establishment of the overall model, define the thermophysical coefficients of different materials in the Property module, including the thermal conductivity, l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com