Electromagnetic type power master switch

An electromagnetic, main switch technology, applied in electromagnetic relays, electromagnetic relay details, circuits, etc., can solve problems such as easy sintering of contact points, poor product on-off capability, magnetic loss, etc., to improve electromagnetic utilization and improve products quality, life extension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

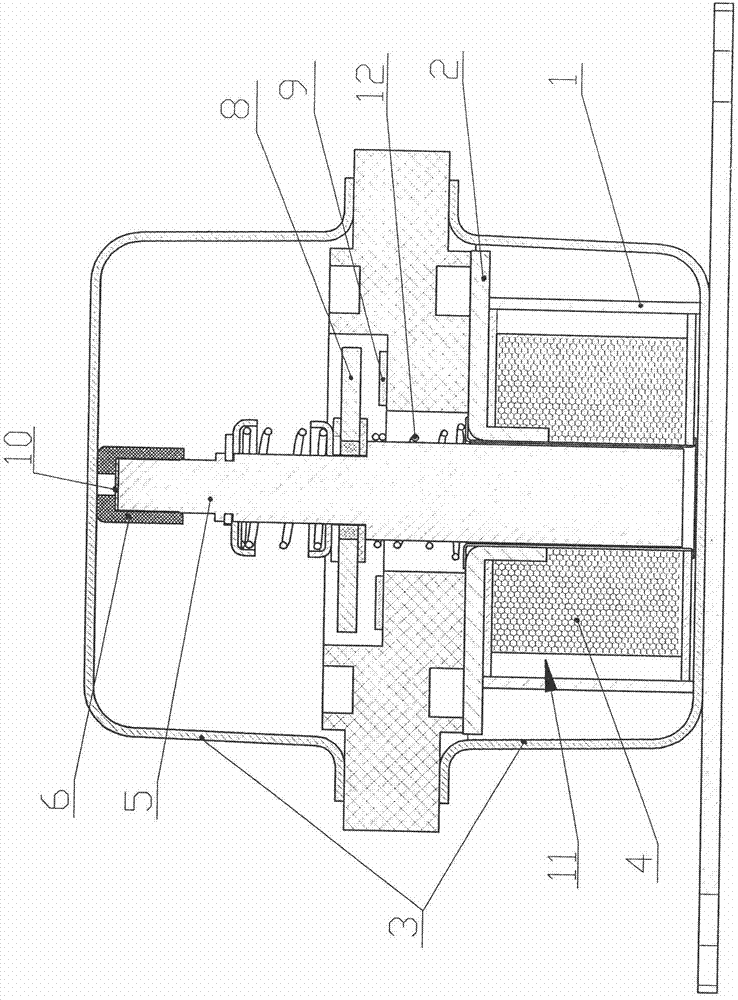

[0009] refer to figure 1 It can be seen that the electromagnetic power supply master switch of the present invention includes an electromagnetic component 11, a casing 3, a push rod 5 (ie, a moving iron core), a movable contact member 8, and a fixed electrode 9, and the upper top of the push rod 5 and the casing 3 Plastic cover 6 is housed between (upper). A gasket 10 is installed between the upper top of the push rod 5 and the plastic sleeve 6, and the fine adjustment of the suction distance of the product is realized by adding the gasket. Wherein, the return spring 12 is also housed on the push rod 5; the part of the push rod (that is, the moving iron core) has been improved, and the length of the entire moving iron core has been lengthened, so that the axial movement can be limited by the casing, Moreover, the internal suction distance can be adjusted through the plastic sleeve on the top of the moving iron core.

[0010] In order to reduce electromagnetic loss and improv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com