High-inductance-value silica-based planar spiral inductor structure

A plane spiral and inductance technology, applied in circuits, electrical components, electric solid devices, etc., can solve the problems of limited use range, large inductance volume, small inductance value, etc., to improve inductance value, reduce eddy current loss, and improve inductance. effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

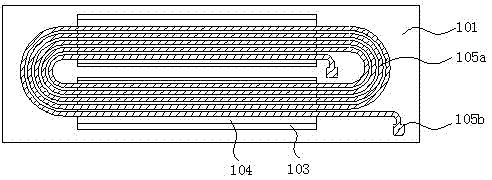

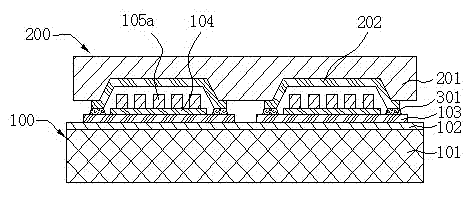

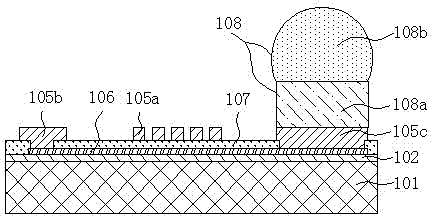

[0048] see figure 1 and figure 2 , the present invention is a high-inductance silicon-based planar spiral inductor structure, including a silicon-based planar spiral inductor 100 and a thin-film silicon cap 200 . The silicon-based planar spiral inductor 100 includes a silicon substrate 101 and a planar spiral inductor coil 105. A passivation layer 102 is deposited on the silicon substrate 101. The passivation layer 102 can be silicon dioxide, silicon nitride or other insulating properties. organic material coating, and the passivation layer 102 completely covers the upper surface of the silicon substrate 101 . The planar spiral inductance coil 105 includes an inductance coil 105a and terminals 105b arranged at both ends of the inductance coil 105a. The inductance coil 105a has a planar spiral structure, and the spiral structure can be rectangular, square, circular or other similar shapes, such as oval, and the number of turns of the inductance coil 105a is usually greater ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com