Pre-charging system and method for modular multilevel inverter

A modular multi-level, pre-charging technology, applied to electrical components, output power conversion devices, AC power input conversion to DC power output, etc., can solve the problems of complex grouping, increased control complexity, etc., to improve the system Safety factor, reduced pre-charge time, simple control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing:

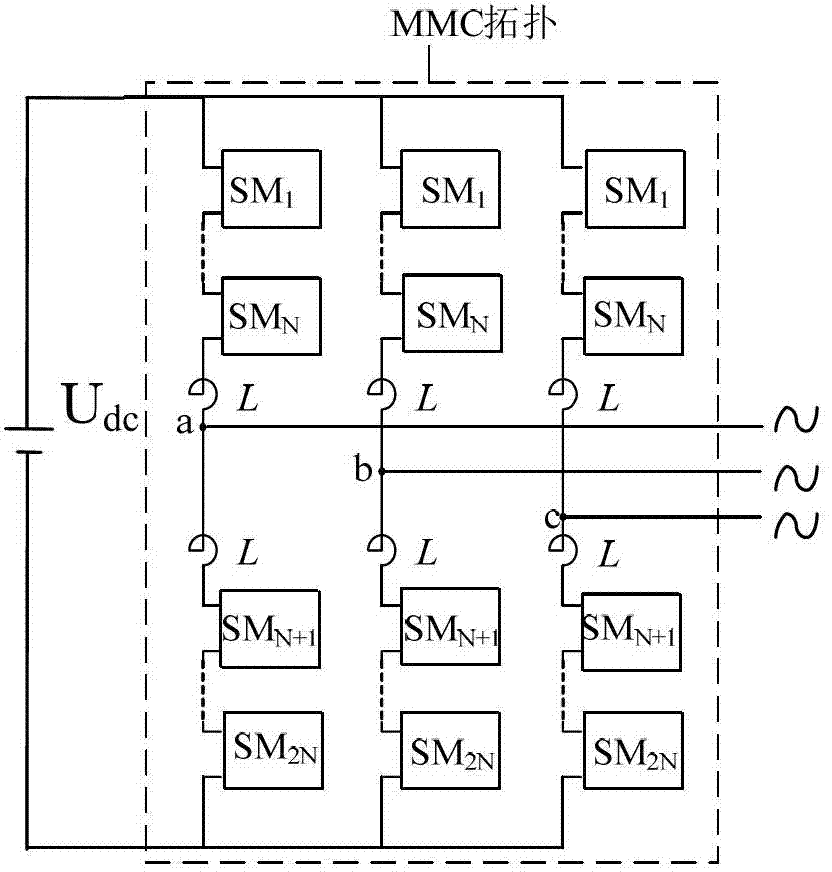

[0031] Such as figure 1 As shown, the three-phase MMC is composed of six bridge arms, and each bridge arm is composed of N submodules and a reactor L connected in series.

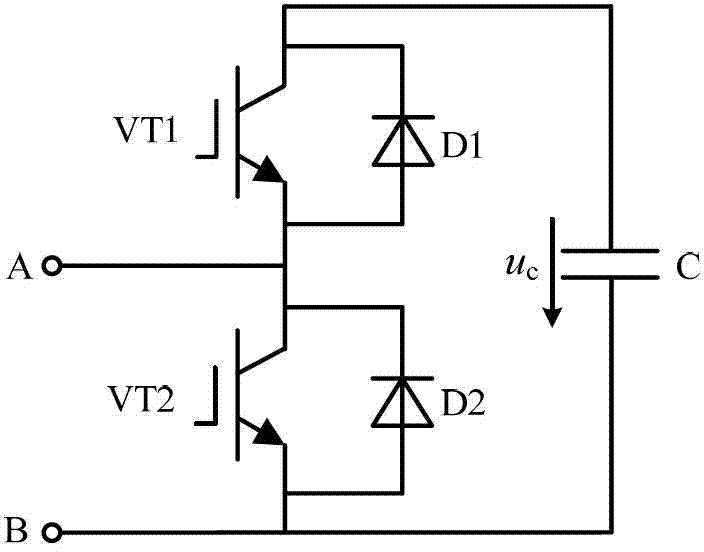

[0032] The structure of the submodule is as follows figure 2 As shown, each sub-module is composed of two switch tubes VT1, VT2 and a capacitor, wherein the switch tubes are connected in antiparallel with diodes, and the capacitors are connected in parallel at both ends of the series switch tubes.

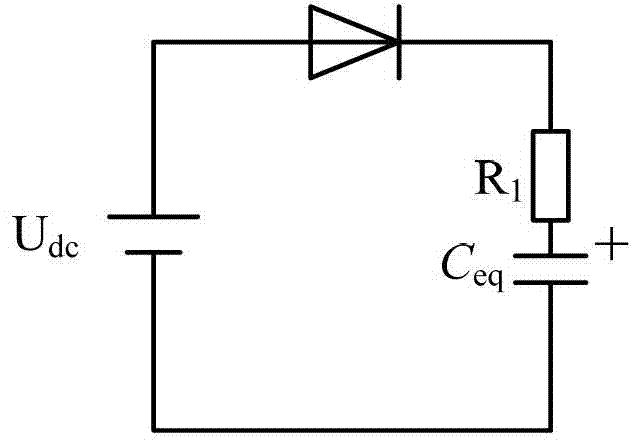

[0033] When precharging, the precharge equivalent circuit such as image 3 shown, which is the current limiting resistor R 1 The equivalent capacitance C after being connected in series and parallel with the bridge arm eq In a typical first-order circuit composed of the bridge arm, the impedance of the series reactance in the bridge arm is very small compared with the impedance of the equivalent capacita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com