Ultrasonic motor full-bridge drive circuit based on double inductors and double capacitors

A full-bridge drive, dual-capacitor technology, applied in piezoelectric/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc. Dynamic performance and other issues, to achieve the effects of fast energy decay, easy speed regulation, and high dynamic response characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below through specific embodiments and related drawings.

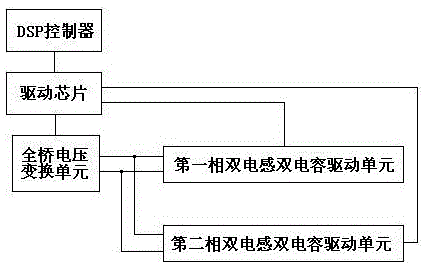

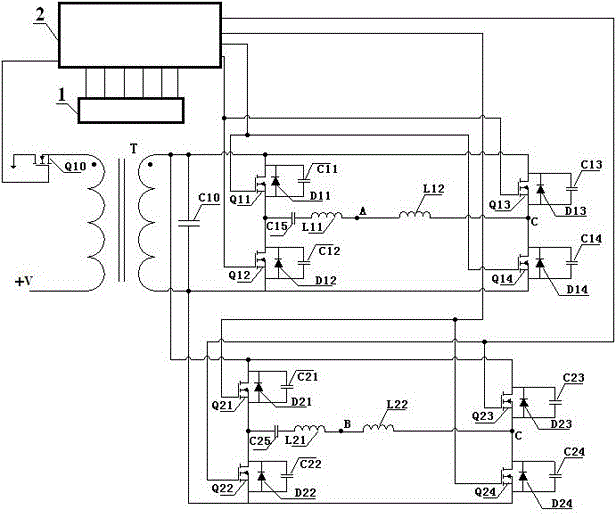

[0015] like figure 1 As shown, the present embodiment provides a full-bridge drive circuit for an ultrasonic motor based on dual inductors and dual capacitors, which is characterized in that it includes a DSP controller, a driver chip, a full-bridge voltage conversion unit, a first phase, dual inductors, and dual A capacitive drive unit and a second-phase dual-inductance dual-capacitor drive unit, the DSP controller is connected to the input end of the drive chip, and the first output end of the drive chip is connected to the first-phase dual-inductance dual-capacitance drive unit the control terminal of the driver chip, the second output terminal of the driver chip is connected to the control terminal of the second-phase dual-inductance dual-capacitance drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com