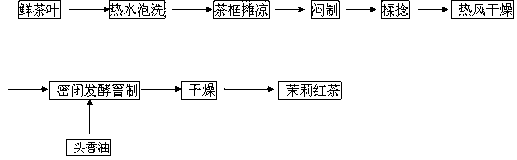

Jasmine black tea scenting method

A technology for making jasmine black tea, which is applied in the directions of tea spice, tea treatment before extraction, etc., can solve the problems of affecting the good quality of black tea, increasing production costs, wasting resources and energy, etc., to improve economic and social benefits, lasting aroma, The effect of uniform shape strips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) 100 parts of freshly picked tea leaves are soaked in hot water at 40°C for 3-10 minutes, then taken out, put in tea baskets and spread out to dry until there is no water drop;

[0031] (2) Take the tea from (1) and put it in a vat, cover and simmer for 5 hours, turn the tea every 0.5 hours, take it out after the simmering, and knead and shape it;

[0032] (3) Dry the tea leaves in (2) to a moisture content of about 8-15% with a 50°C airflow;

[0033] (4) Put the tea leaves of (3) into an airtight container for airtight scenting and fermentation. Take 0.01 part of jasmine head sesame oil and 5 kg of drinking water and add them into an atomizer and spray them into a closed container. Adjust the temperature of the closed container to 25°C, the humidity to 70%, and the pressure to 20kPa. Scent and ferment for 8 hours.

[0034] (5) Take out the scented jasmine black tea and dry it with hot air at about 120°C to less than 7%, let it cool and pack it to be the finished prod...

Embodiment 2

[0036] (1) 100 parts of freshly picked tea leaves are soaked in hot water at 55°C for 5-10 minutes, then taken out, put in tea baskets and spread out to dry until there is no water drop;

[0037] (2) Take the tea from (1) and put it in a vat, cover and simmer for 12 hours, turn the tea every 0.5 hours, take it out after the simmering, and knead and shape it;

[0038] (3) Dry the tea leaves in (2) to about 12% with a medium-temperature airflow at 65°C;

[0039] (4) Put the tea leaves of (3) into an airtight container for airtight scenting and fermentation. Get 0.15 parts of jasmine head sesame oil and 12 kg of drinking water into an atomizer and spray into a closed container. Adjust the temperature of the closed container to 43°C, the humidity to 84%, and the pressure to 110kPa. Scent and ferment for 28 hours.

[0040] (5) Take out the scented jasmine black tea and dry it with hot air at about 120°C to less than 7%, let it cool and pack it to be the finished product.

Embodiment 3

[0042] (1) 100 parts of freshly picked tea leaves are soaked in hot water at 70°C, taken out, put in tea baskets and spread out to dry until there is no water drop;

[0043] (2) Take the tea from (1) and put it in a vat, cover and simmer for 20 hours, turn the tea every 0.5 hours, take it out after the simmering, and knead and shape it;

[0044] (3) Dry the tea leaves in (2) to a water content of about 12% with a medium-temperature airflow at 80°C;

[0045] (4) Put the tea leaves of (3) into an airtight container for airtight scenting and fermentation. Get 0.30 parts of jasmine head sesame oil and 25 kg of drinking water into an atomizer and spray into a closed container. Adjust the temperature of the closed container to 60°C, the humidity to 98%, and the pressure to 200kPa. Scent and ferment for 48 hours.

[0046] (5) Take out the scented jasmine black tea and dry it with hot air at about 120°C to less than 7%, let it cool and pack it to be the finished product.

[0047] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com