Self-propelled channel beam transport vehicle

A trough-shaped beam and self-propelled technology, applied in the direction of transportation and packaging, vehicles used to carry long goods, vehicle parts, etc., can solve problems such as difficulty in reversing, tractor power limitation, danger, etc., to save construction costs, Improving transportation efficiency and strong site adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

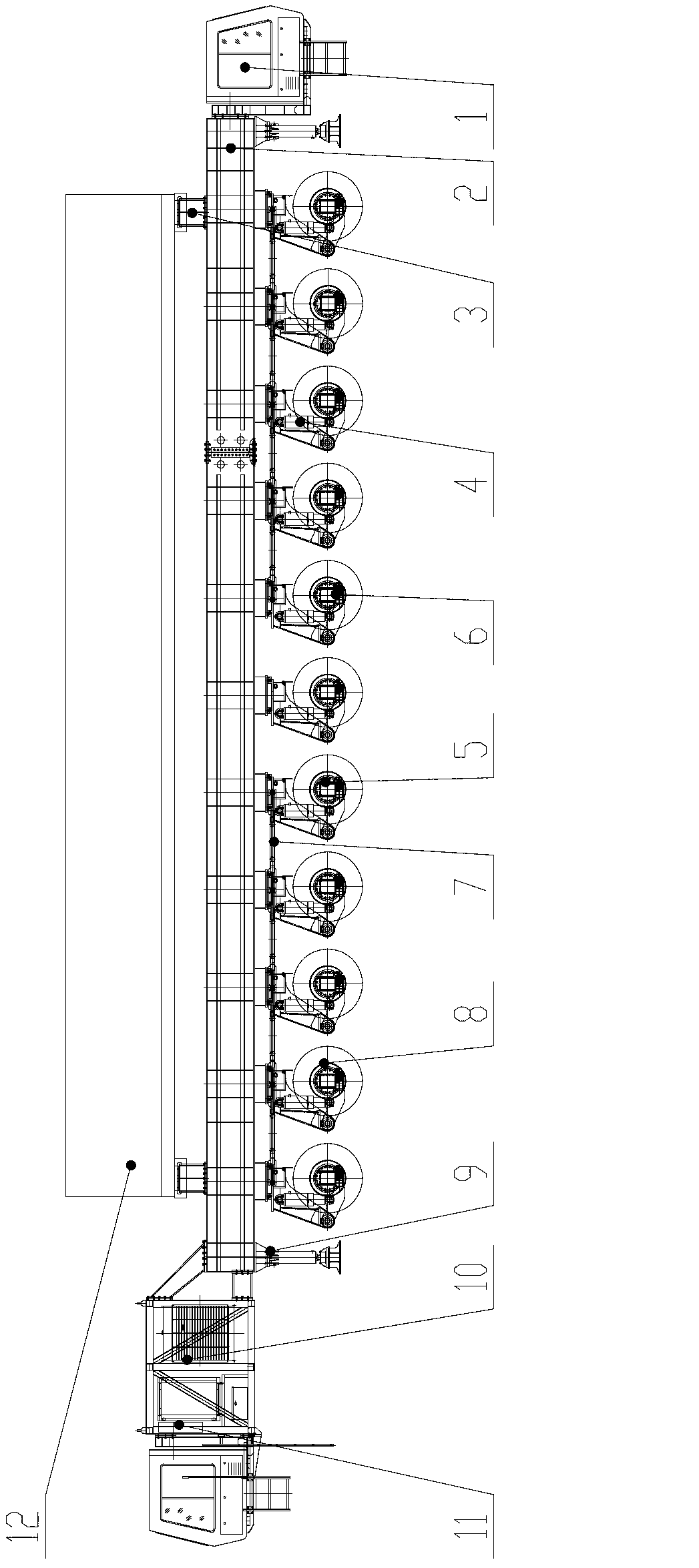

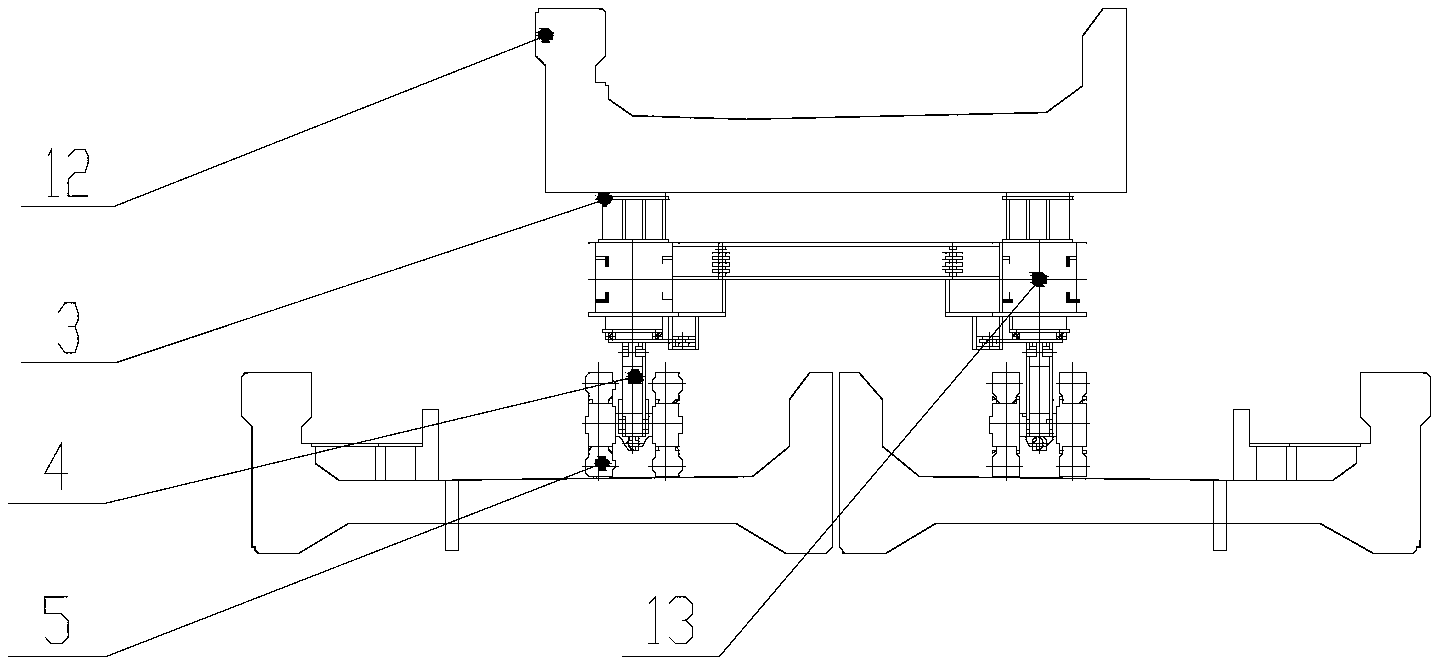

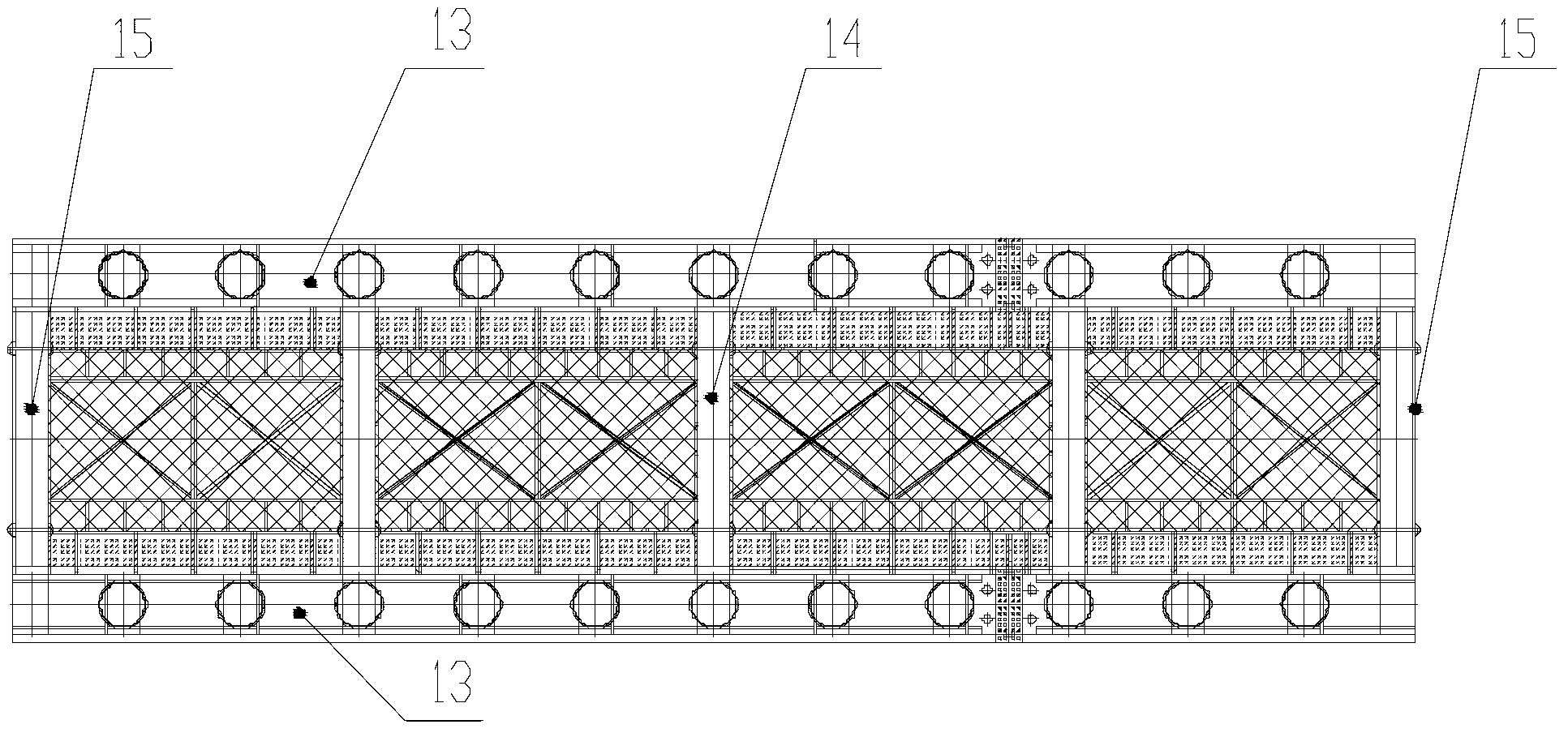

[0031] Such as Figure 1 to Figure 5As shown, the self-propelled trough beam transport vehicle of the present invention consists of a cab 1, a main structure 2, a support point 3, a power system 10, a hydraulic suspension 4, a drive axle 6, a driven axle 5, a steering system 7, and a braking system 8. The outrigger 9 and the electro-hydraulic control system 11 are composed of components such as the main structure 2, which is a force-bearing part. The main structure 2 includes a pair of symmetrically arranged main beams 13 and a cross beam 14 connected between the pair of main beams 13 The inverted "concave" main frame structure composed of end beams 15, the driving bridge 6 and the driven bridge 5 are connected to the lower ends of the main beams 13 on both sides of the main structure 2 through hydraulic suspension 4, and at the same time, the lower part of the main structure 2 is set Four hydraulic support legs 9, four bolsters 3 are arranged on the top, to carry the trough b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com