Forming method and structure of aluminum alloy surface interference film

A technology of aluminum alloy surface and interference film, which is applied in the direction of surface reaction electrolytic coating, anodic oxidation, electrolytic coating, etc., can solve the problem of inability to produce interference film with different colors at multiple angles, and achieve the effect of increasing ornamental

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Firstly, an aluminum alloy workpiece is provided. The aluminum alloy workpiece can be a shell or a rod of any device, such as an outer shell of an electronic product, a body of a bicycle, or a small decorative metal piece.

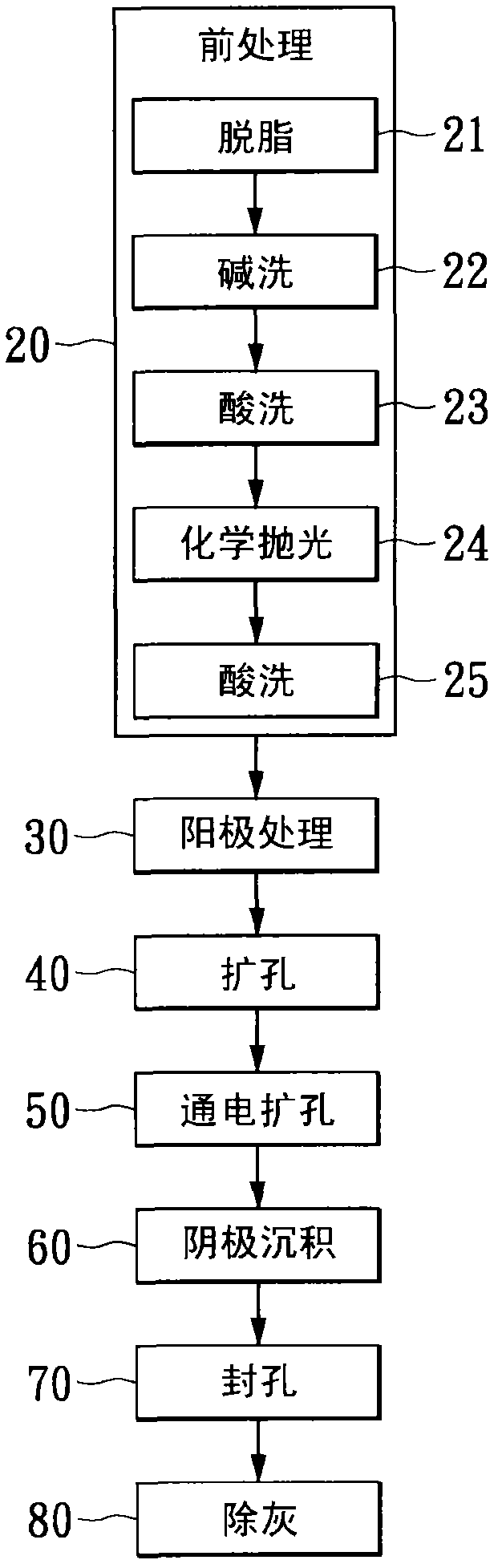

[0029] Next is step 20, pre-treating the aluminum alloy workpiece to clean its surface; referred to as "pre-treatment" process, which includes at least five sub-processes;

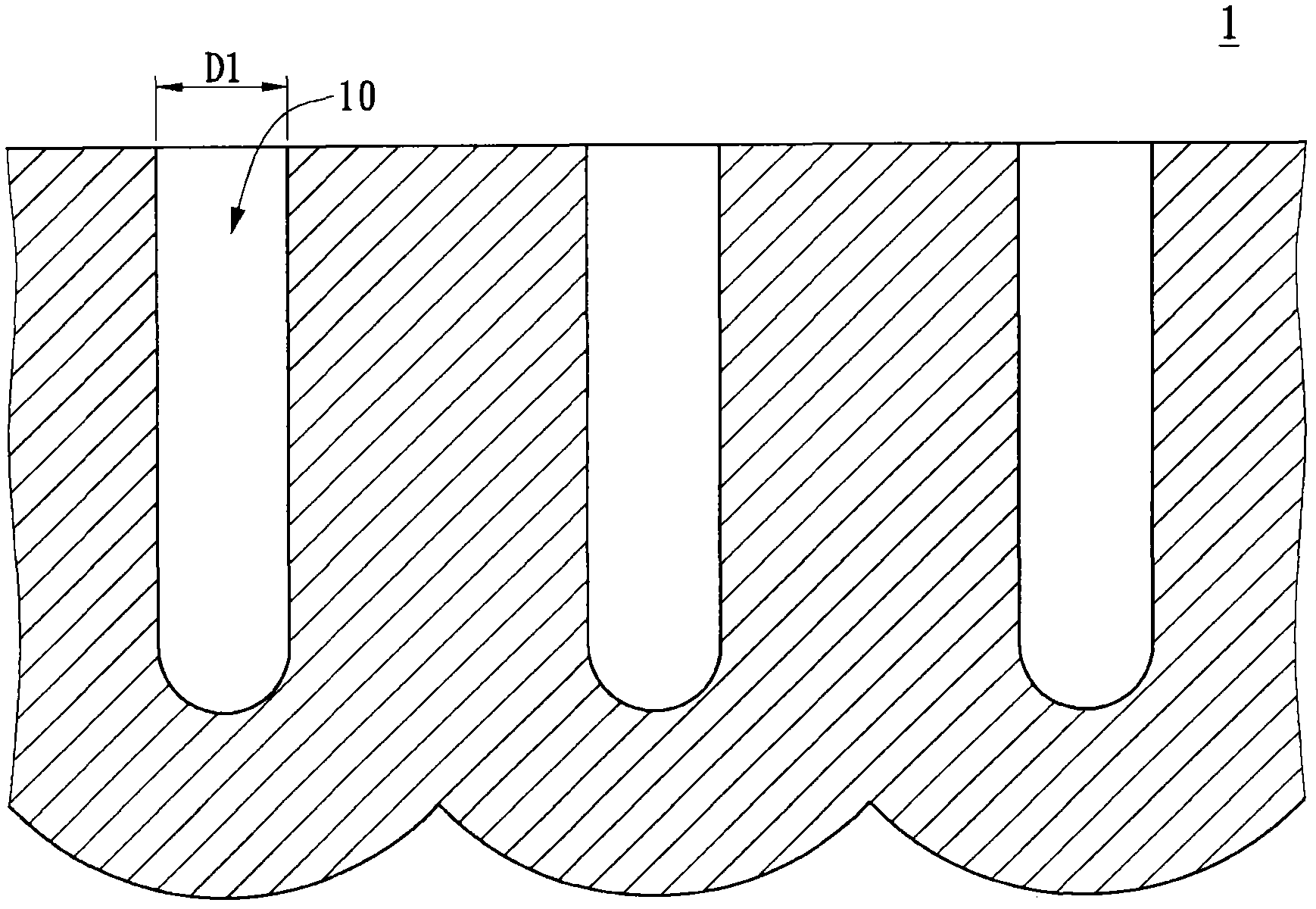

[0030] Step 30, anodizing the aluminum alloy workpiece for a predetermined time until an oxide film with a plurality of tracheid micropores is formed on the surface; referred to as "anodizing" process;

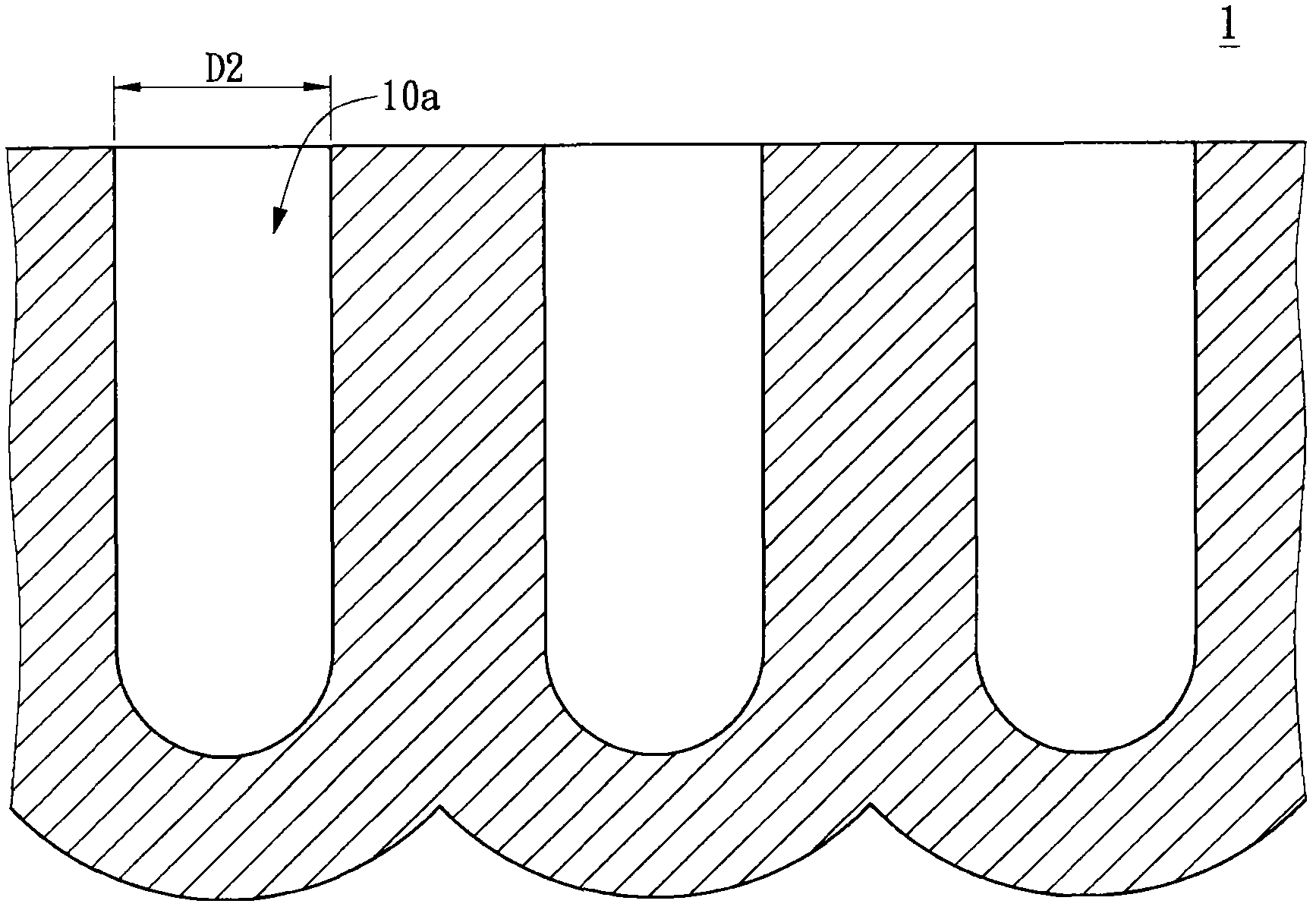

[0031] Step 40, expand the oxide film of the aluminum alloy workpiece with an acidic solution to expand the pore diameter of the tracheid micropores; referred to as the "pore expansion" process, this process does not need to be powered;

[0032] Step 50, energizing pore reaming treatment to expand the bottom of the tracheid micropores and form a deposition area; referred to as "...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com