Partial double-layer spherical reticulated shell storage tank vault structure

A reticulated shell and double-layer technology, which is applied in the field of storage tank vault structure, can solve the problems of complicated design and construction of double-layered reticulated shell, and achieve the effects of improving overall stability, saving steel, and large bearing capacity of the vault.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

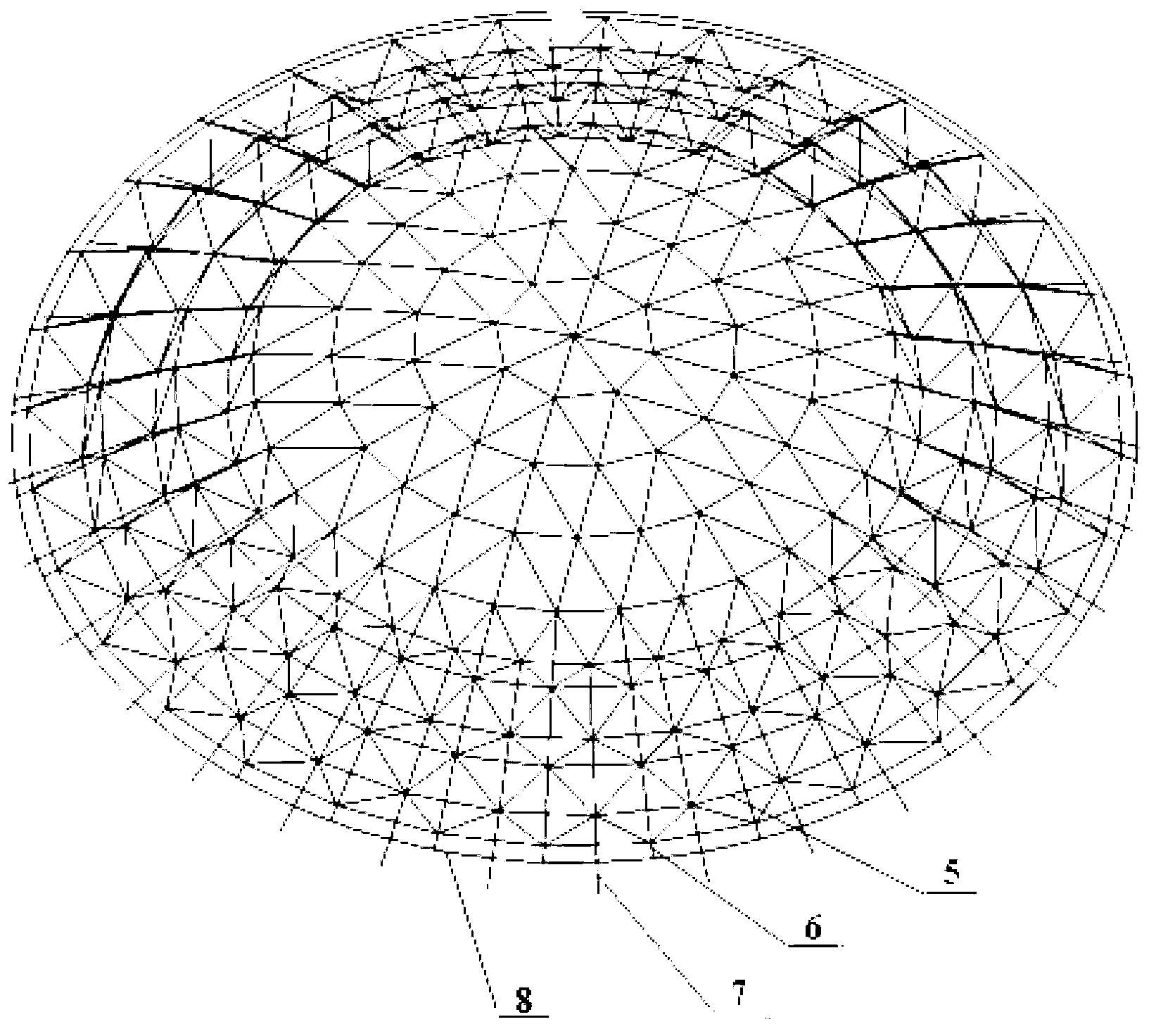

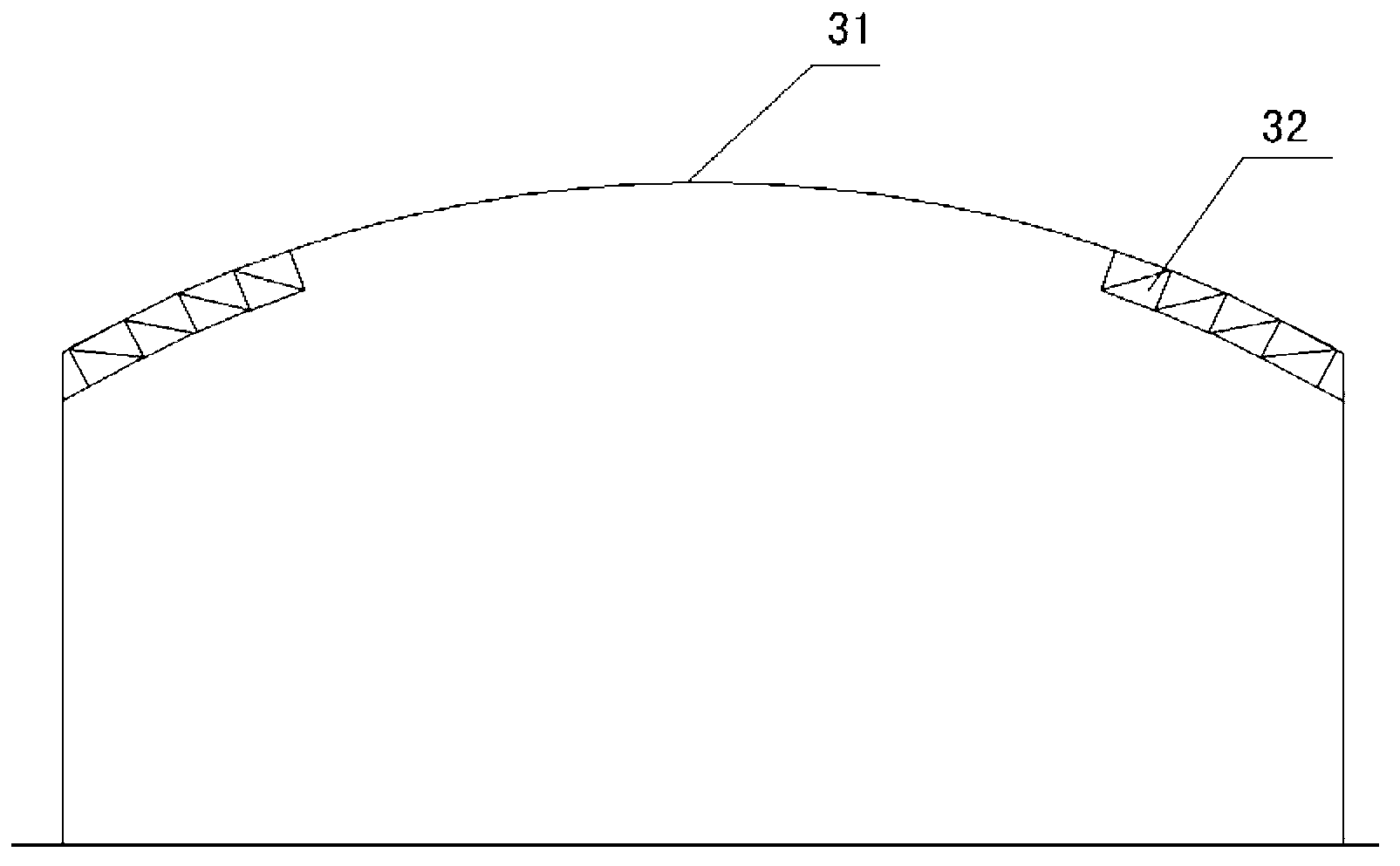

[0028] see figure 1 , figure 2 , the structure of the local double-layer spherical reticulated shell storage tank vault in the present embodiment is: the middle part of the storage tank vault is set as a Kaiwitt type single-layer spherical reticulated shell 31, which is formed by connecting rods and nodes; the storage tank vault The outer periphery is a double-layer reticulated shell 32 with an outer net and an inner net formed by connecting the rods and nodes.

[0029] In the specific implementation, the corresponding structure is set as:

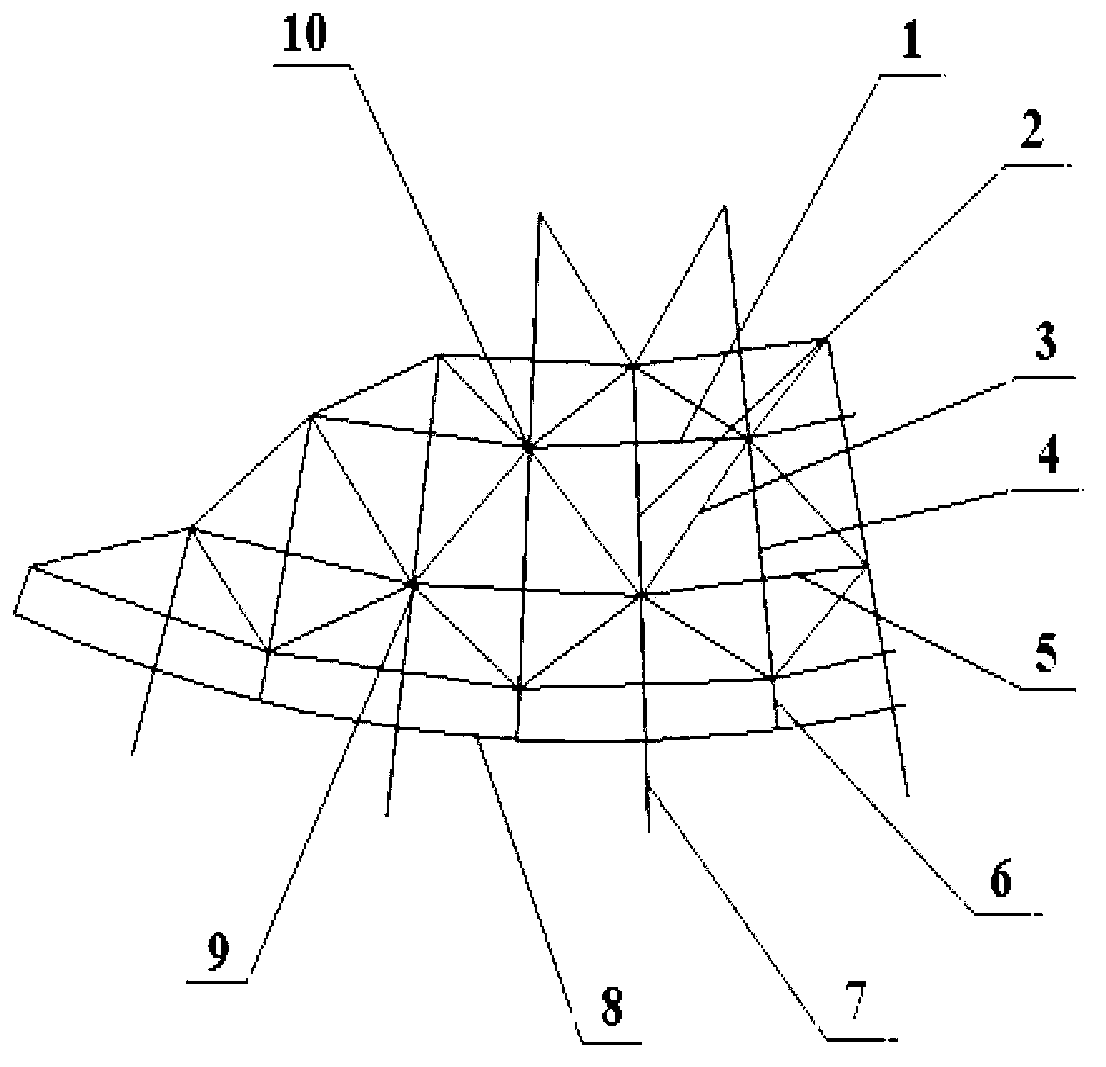

[0030] Such as image 3 with Figure 4 As shown, the outer mesh in the double-layer reticulated shell in this embodiment adopts rib ring mesh, and the rib ring mesh and the inner layer mesh form a quadrangular pyramid system, and the thickness of the double-layer reticulated shell is 2-3 meters. The double-layer reticulated shell structure is set as follows: two adjacent rib ring network ring rods 1 and two adjacent rib ring network r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com