An implantable heavy oil well sand monitoring device

A monitoring device and implantable technology, which is applied in the directions of measurement, wellbore/well components, earthwork drilling and production, etc., can solve problems such as difficulty in monitoring sand content changes in oil flow, short service life, monitoring delay, and high viscosity of crude oil, etc., to achieve The monitoring effect is real and credible, the operation is convenient and the cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

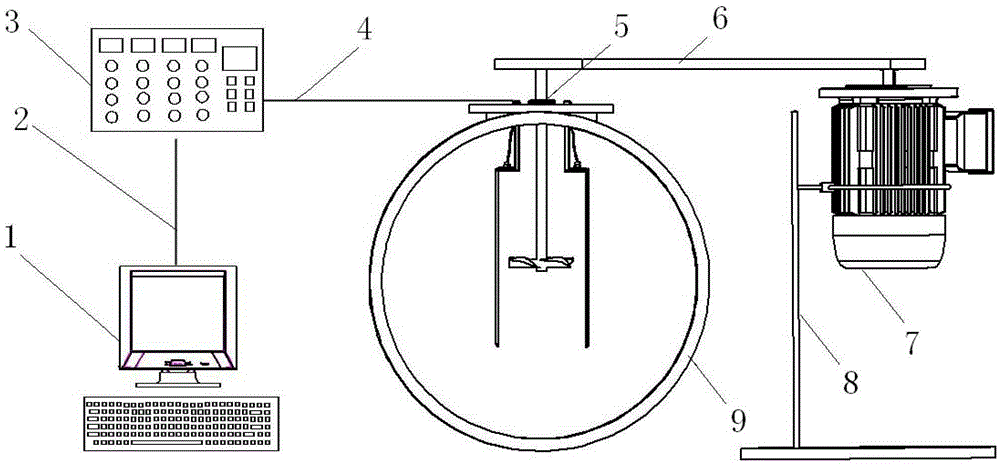

[0013] Such as figure 1 As shown, the present invention includes a computer 1, a signal cable 2 connected to the computer, a signal acquisition instrument 3 connected to the signal cable 2, a signal cable 4 connected to the signal acquisition instrument 3, and an implant device 5 connected to the signal cable 4, A set of belt transmission device 6 that drives the implantation device 5 to rotate, a motor 7 that drives the belt transmission device 6 , a fixed bracket 8 and a production pipeline 9 that are fixedly installed with the motor 7 .

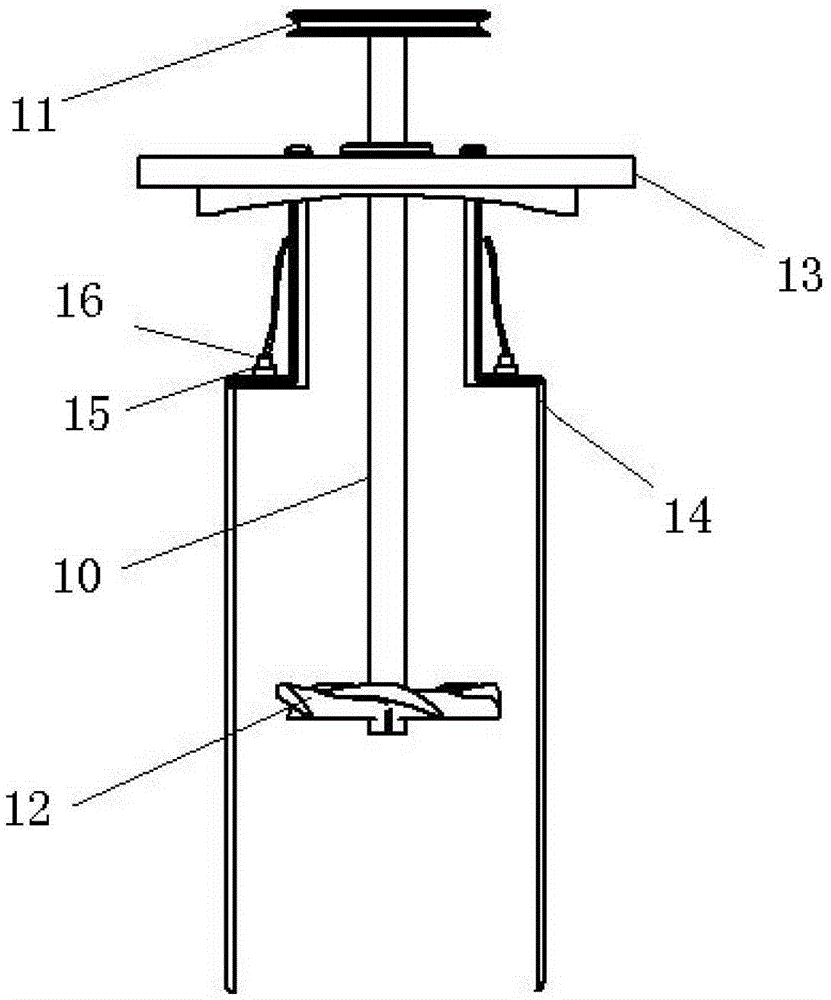

[0014] Such as figure 2 As shown, the implantation device 5 of the present invention includes a sand vibrator 10, the top of the sand vibrator 10 is connected with a pulley 11 of the belt drive 6, and the bottom of the sand vibrator 10 is connected with a belt for accelerating sand grains. The impeller 12, the upper pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com