Independent primary air system provided with heat pipe exchanger and working method thereof

A technology of heat pipe heat exchanger and fresh air system, which is applied in the direction of ventilation system, heating and ventilation control system, heating and ventilation safety system, etc. It can solve the problems of reducing indoor air quality, occupying a large space, and cross-contamination, so as to improve indoor air quality. Air quality, low maintenance costs, and high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

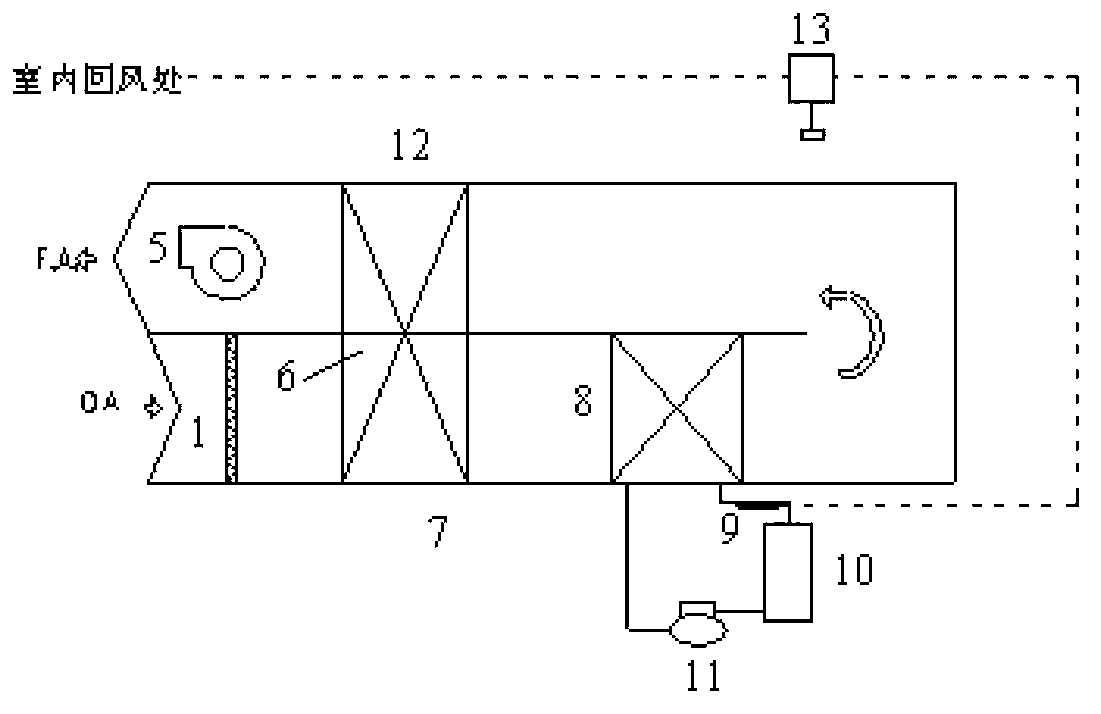

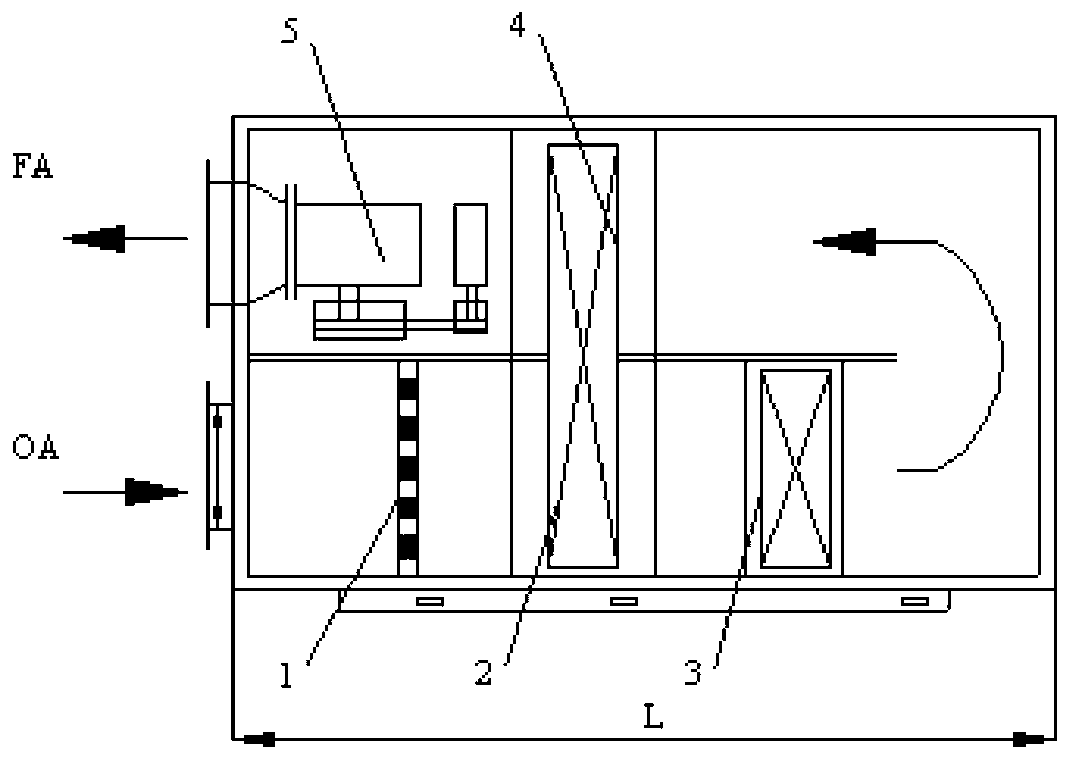

[0050] Embodiment: a kind of independent fresh air system that contains heat pipe heat exchanger (see Figure 2 to Figure 4 ), characterized in that it includes a pre-cooling unit 2, cooling and dehumidifying unit 3, reheating unit 4 and air supply unit 5; the pre-cooling unit 2, cooling and dehumidifying unit 3, reheating unit 4 and air supply unit 5 are installed in sequence Between the inlet and the outlet of the fresh air system; the air supply unit 5 is installed at the outlet of the fresh air system.

[0051] A filter unit 1 is installed at the inlet of the fresh air system. (See Figure 2 to Figure 4 )

[0052] The entrance and exit of the fresh air system are equipped with a damper actuator M and a differential air pressure switch ΔP; the air inlet side and the air outlet side of the precooling unit 2 and the reheating unit 4 are equipped with temperature and humidity sensors TH; the air supply unit 5 is connected to the frequency converter V; the fresh air system i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com