Device and method used for drying materials

A drying and control device technology, applied in the direction of drying solid materials, heating devices, tobacco drying, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

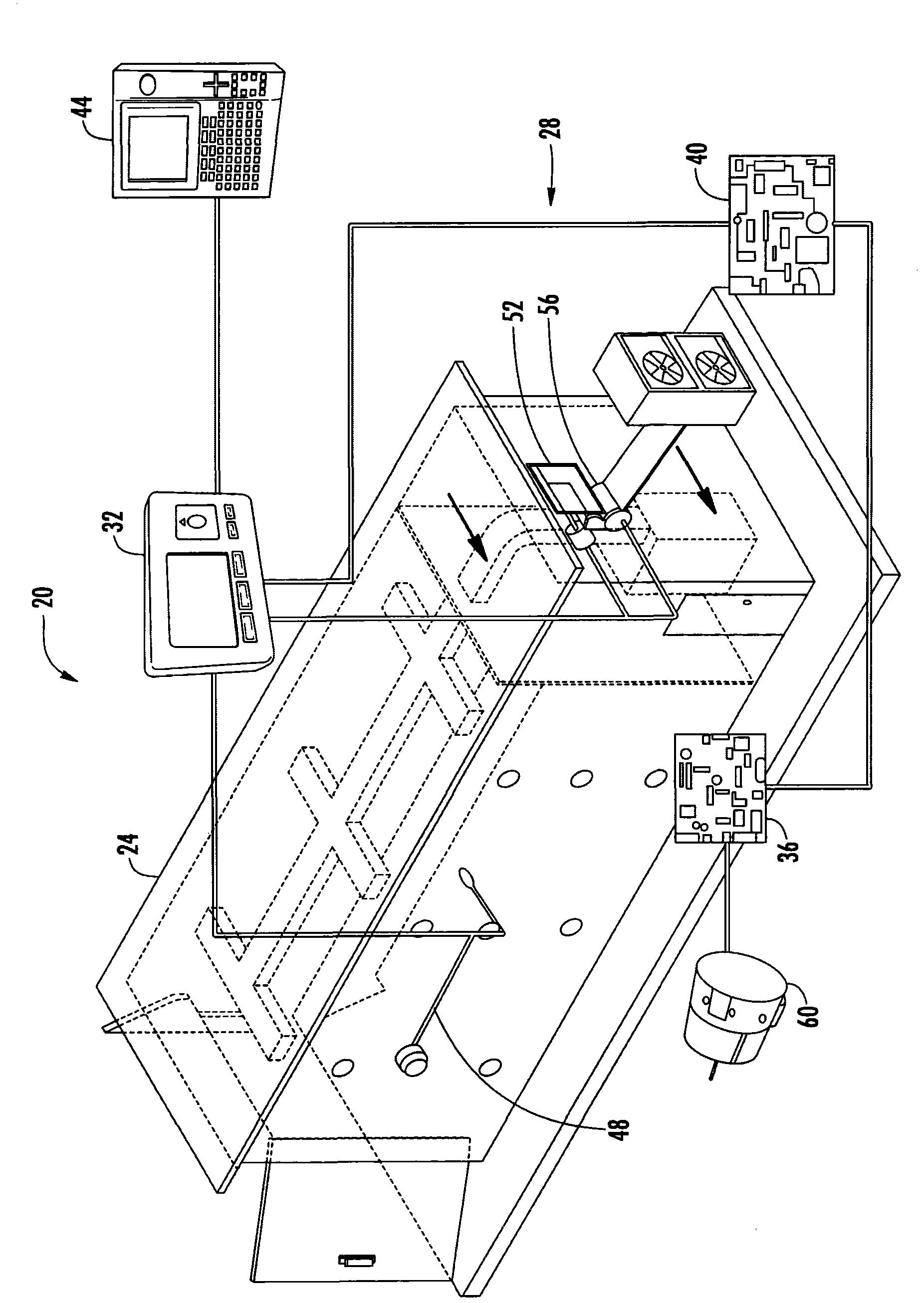

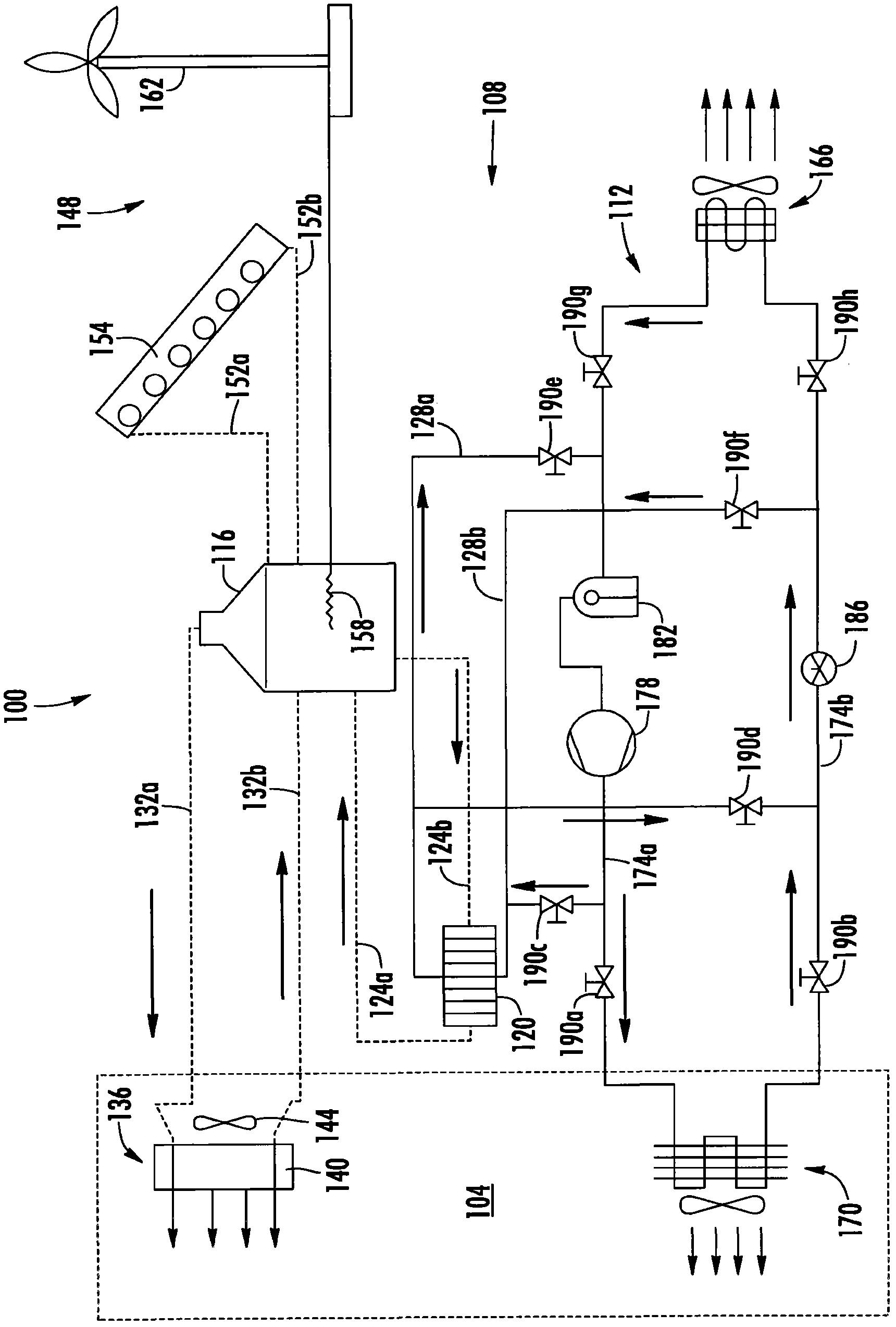

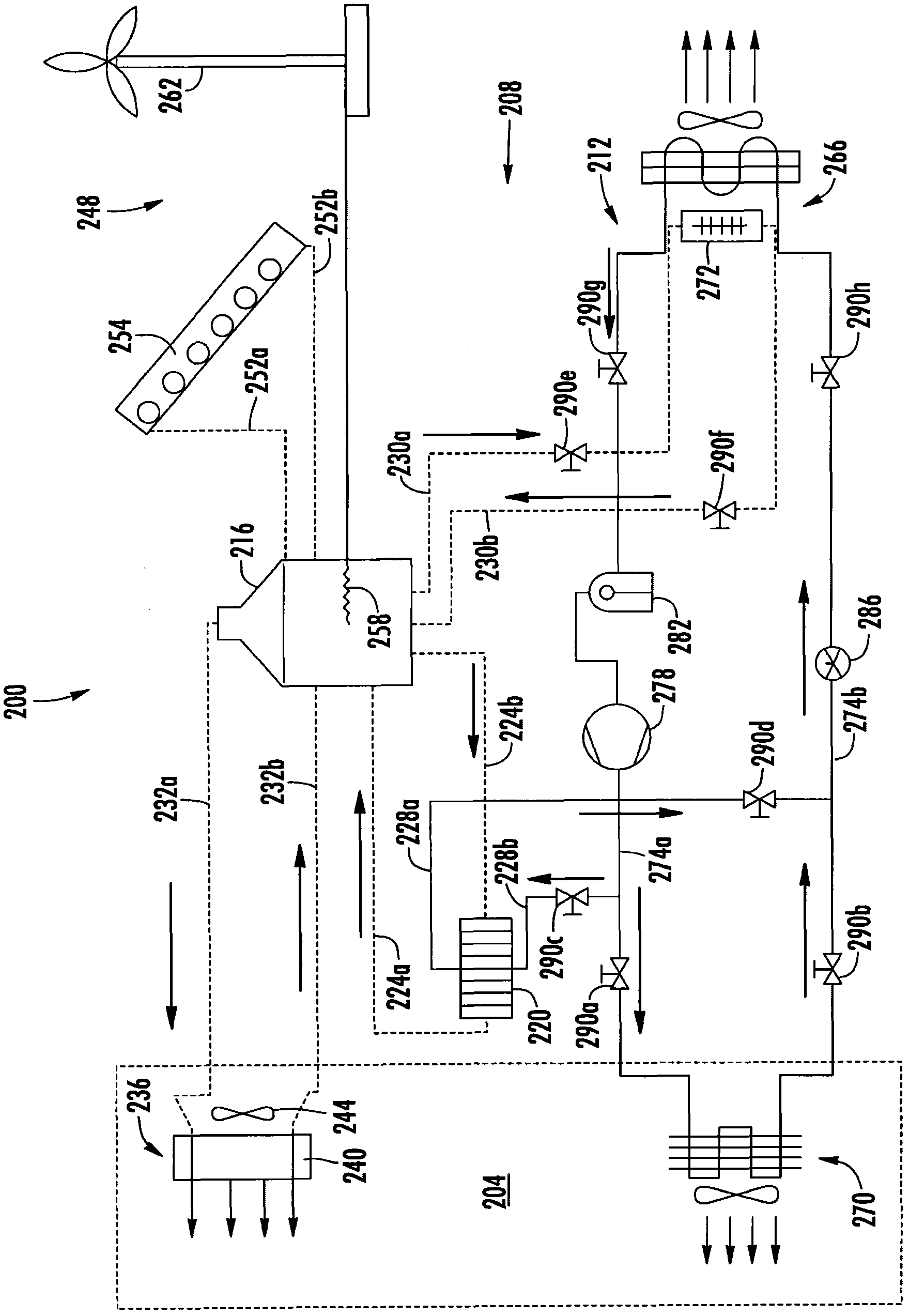

[0019] Exemplary embodiments will be described more fully with reference to the accompanying drawings.

[0020] In the present invention, various exemplary embodiments or examples relate to systems for drying materials including, but not limited to, tobacco and the like. The drying system comprises control means configured to be selected from a plurality of different kinds of heat sources, one or more of which are renewable, for example to help increase (or preferably optimize) the supply of heat to, for example, the drying chamber , and / or improve (or preferably maximize) energy savings. The choice of heat source is determined for example based on the temperature in the drying chamber and the temperature of the fluid in the heat storage. The fluid in the heat storage can be heated by one or more auxiliary heat sources, for example by solar installations, and / or by means of electrical current from wind and / or hydropower, and / or by energy obtained from a utility power station....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com