Ridge soil sampler

A soil sampler and ridge technology, which is applied in the fields of environmental science research and soil science, can solve the problems of destroying the ridge body and soil structure, being random and easy to slip, achieving good sampling representativeness, improving sampling efficiency, and using handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

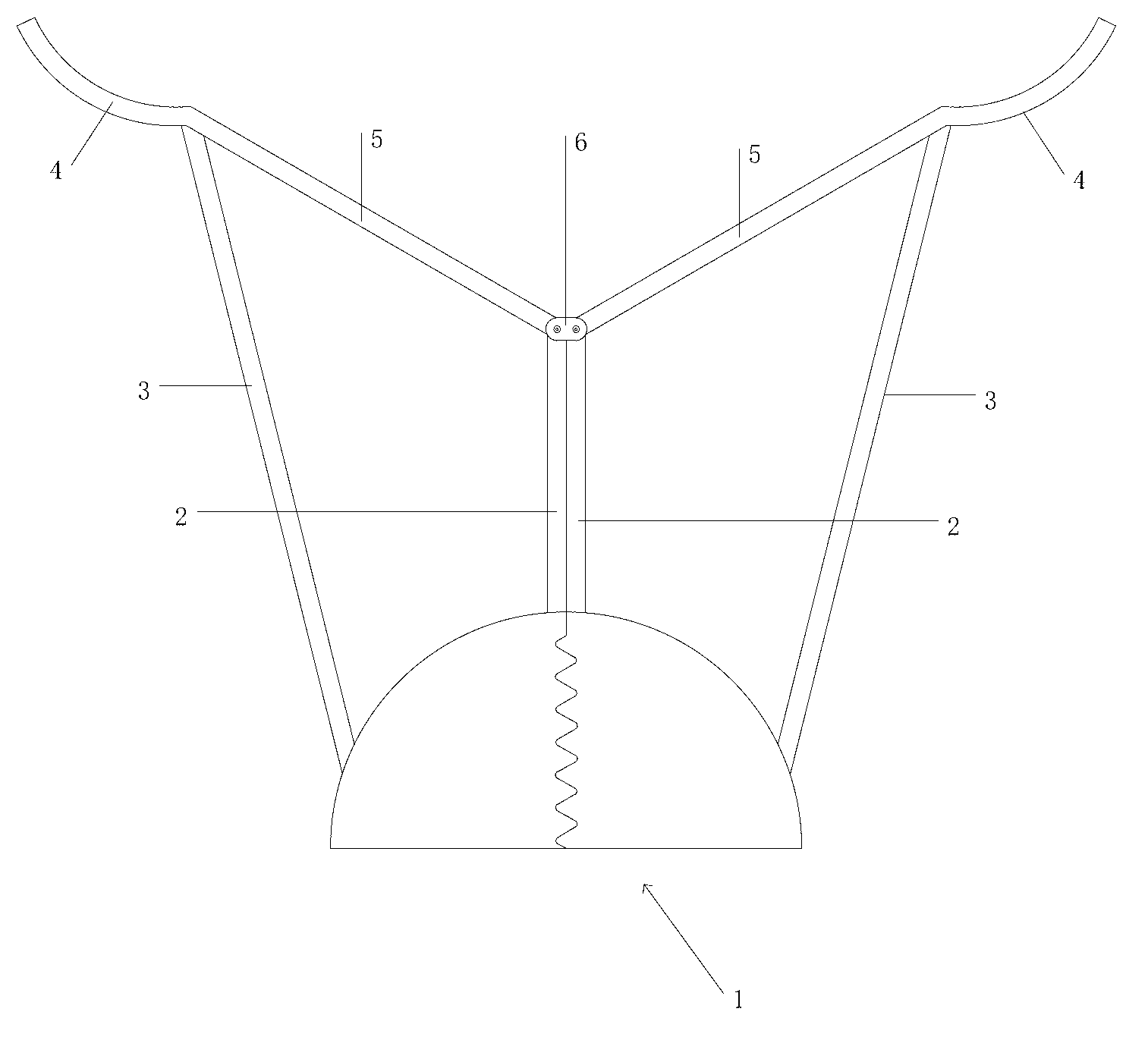

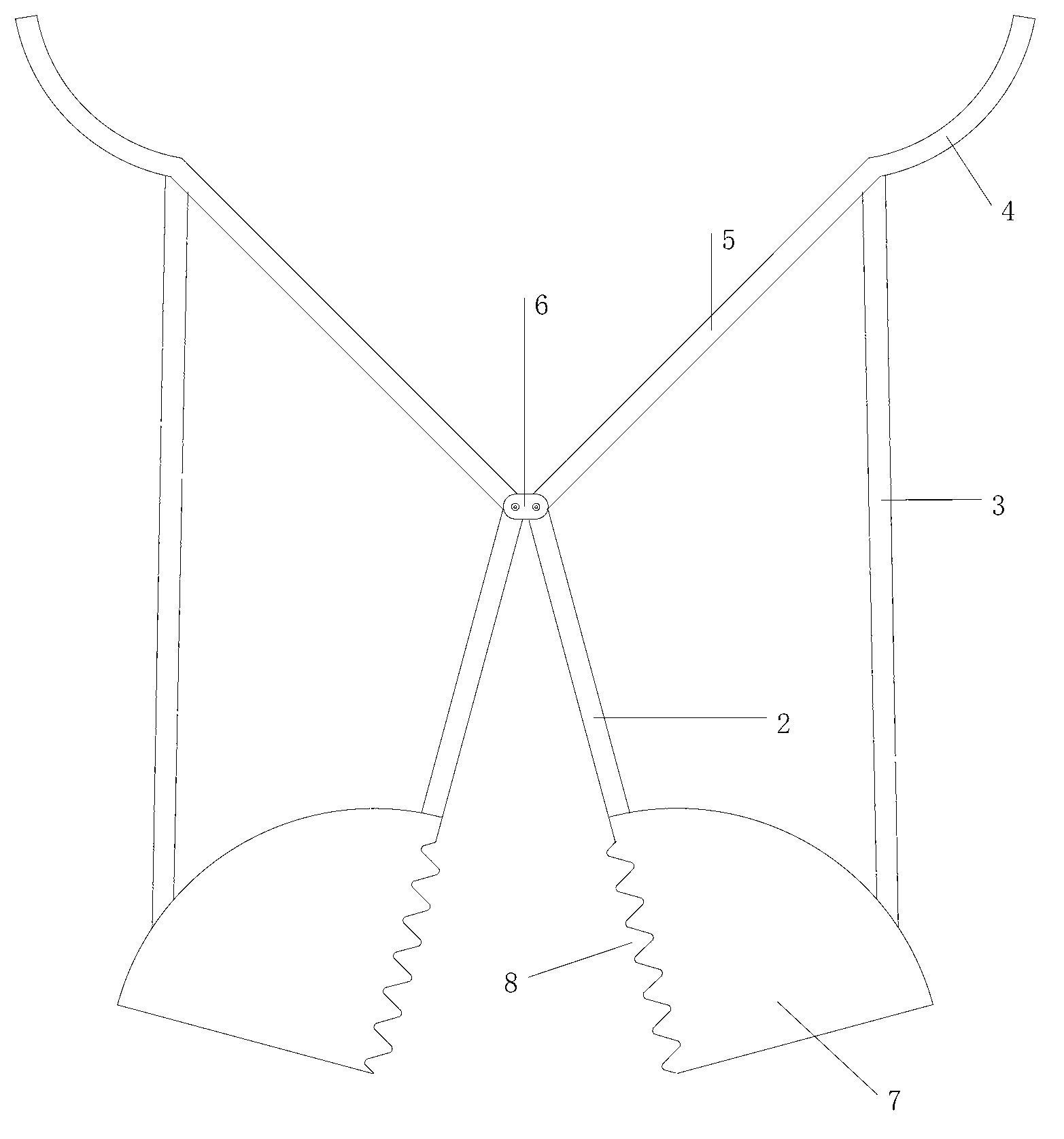

[0028] see figure 1 with figure 2 , The present invention includes a sampling head 1, a connecting rod 2, a support rod 3, a handle 4 and a lever 5. One end of the lever 5 is affixed to the handle 4, the other end is hinged to one end of the connecting rod 2 through the pivot device 6, the other end of the connecting rod 2 is affixed to the top of the sampling head 1; one end of the support rod 3 is affixed to the handle 4, The other end is fixedly connected with the sampling head 1. The sampling head 1 is composed of two hollow 90° fan-shaped grab buckets 7 . The fan-shaped grab 7 is provided with a sampling port 8, and the sides of the sampling port 8 are wavy or serrated, and the sampling ports 8 of the two fan-shaped grab buckets 7 can be tightly meshed.

[0029] The sampling head 1, the support rod 3 and the lever 5 form a stable quasi-triangular support structure. The side of the fan-shaped grab sampling port 8 is set in a wavy or sawtooth shape, which is convenient...

Embodiment 2

[0036] Except following difference, other is with embodiment 1.

[0037] The fan-shaped grab bucket 7 is welded by hard 304 stainless steel plate, and the thickness of the steel plate is not less than 1.2mm. Support bar 3 and handle 4 can be made up of circular or square stainless steel pipe, reduce weight. The connection between the lever and the handle, the support rod and the handle, the support rod and the sampling head, etc., can all be connected by bolts, which are detachable and easy to carry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com