Soft and hard circuit board combined type light-emitting diode (LED) display module

A technology for LED display screens and soft and hard circuit boards, which is applied in printed circuit components, structural connections of printed circuits, instruments, etc., and can solve the problem of adapting the shape of the installation surface, failing to maintain the overall screen flatness and installation stability, Increase the difficulty of manufacturing LED circuit boards, etc., to achieve the effect of easy fixing and stable welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

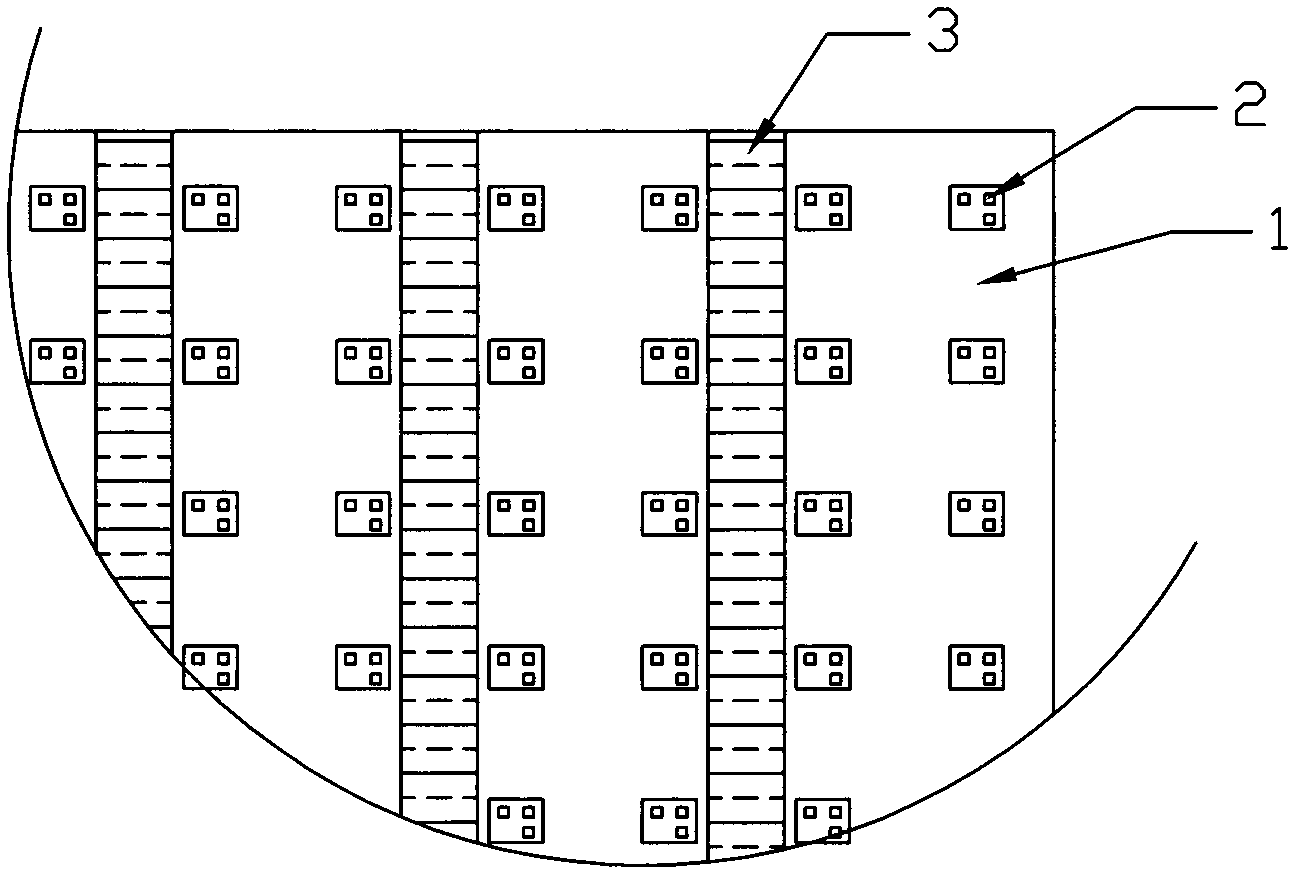

[0011] Such as figure 1 As shown, the flexible and rigid circuit board combined LED display module of this embodiment includes a plurality of rigid circuit boards 1, and the rigid circuit board 1 is provided with a plurality of LED light sources 2 arranged uniformly. The adjacent rigid circuit boards are connected to the circuits on the adjacent rigid circuit boards through the flexible circuit boards. A via hole with electrical properties is drilled in the middle to realize the wiring between the two circuit boards. Then the two boards are superimposed and fixed through the pressing process.

[0012] Such as figure 1 As shown, in this embodiment, the circuit board 1 is rectangular, and the plurality of circuit boards 1 are arranged in one row and multiple columns.

[0013] Apart from figure 1 In addition to the structure shown, there may be other combinations between the rigid circuit board and the flexible circuit board, for example, the plurality of rigid circuit boards...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com