DPF system

A diesel and particle filter technology, applied in the field of DPF system, can solve the problems of reducing dosage deviation, unstable exhaust gas temperature, and inability to perform stable temperature control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, preferred embodiments of the present invention will be described based on the drawings.

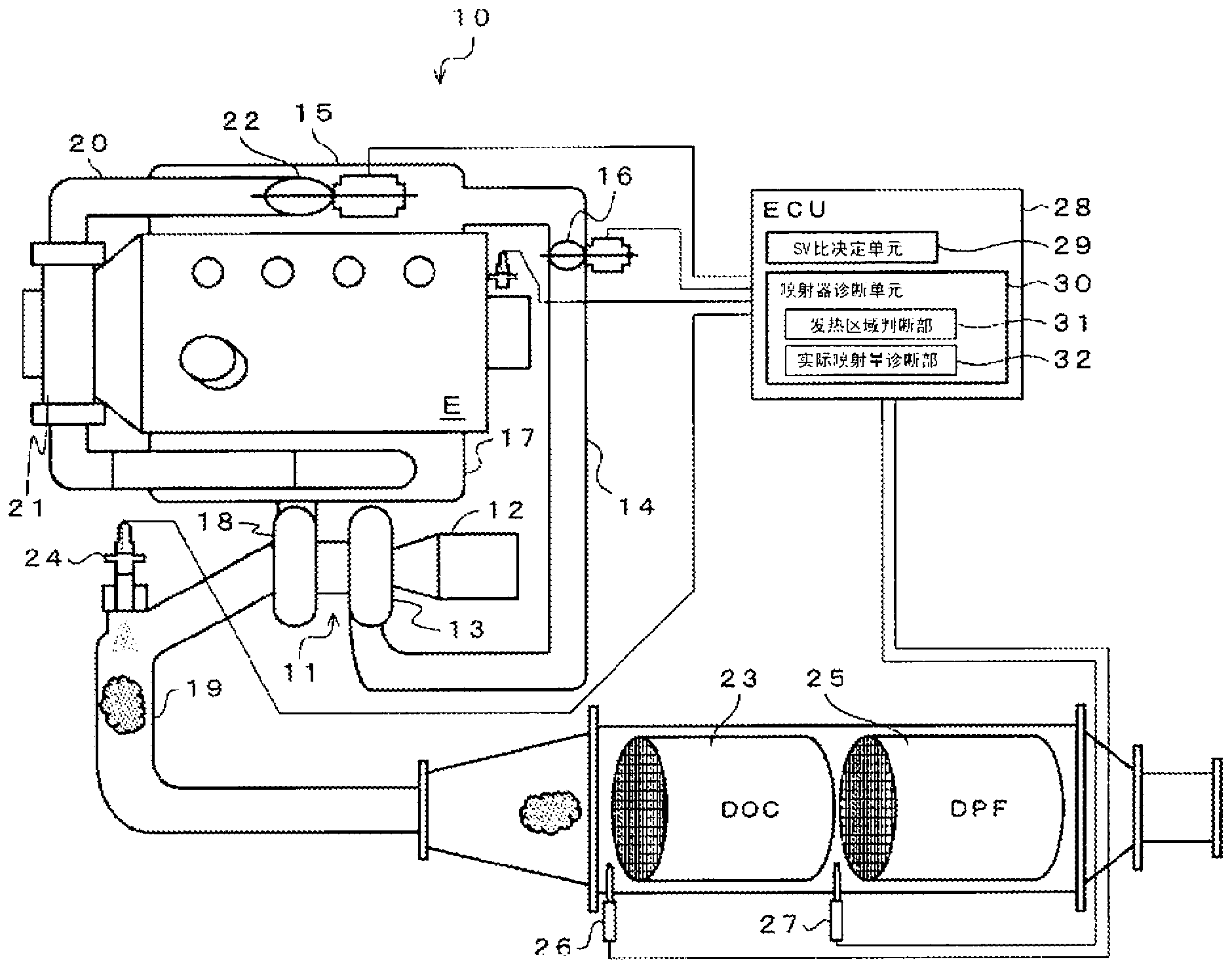

[0025] figure 1 It is a schematic diagram showing the structure of the DPF system of this embodiment.

[0026] The DPF system 10 of the present embodiment is equipped with a turbocharger 11, the air sucked in from the air cleaner 12 is compressed by the compressor 13 of the turbocharger 11, and is pressure-fed to the intake passage 14, and the air from the intake passage 14 The intake manifold 15 connected to 14 supplies the engine E. An intake valve 16 for adjusting the amount of air supplied to the engine E is provided on the intake passage 14 .

[0027] Exhaust gas exhausted from the engine E flows into and drives a turbine 18 of the turbocharger 11 from an exhaust manifold 17 , and is exhausted to an exhaust pipe 19 .

[0028] The DPF system 10 includes: an EGR pipe 20 connecting the intake manifold 15 and the exhaust manifold 17; an EGR cooler 21 for cooling th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com