Fire resistant back-heet for photovoltaic module

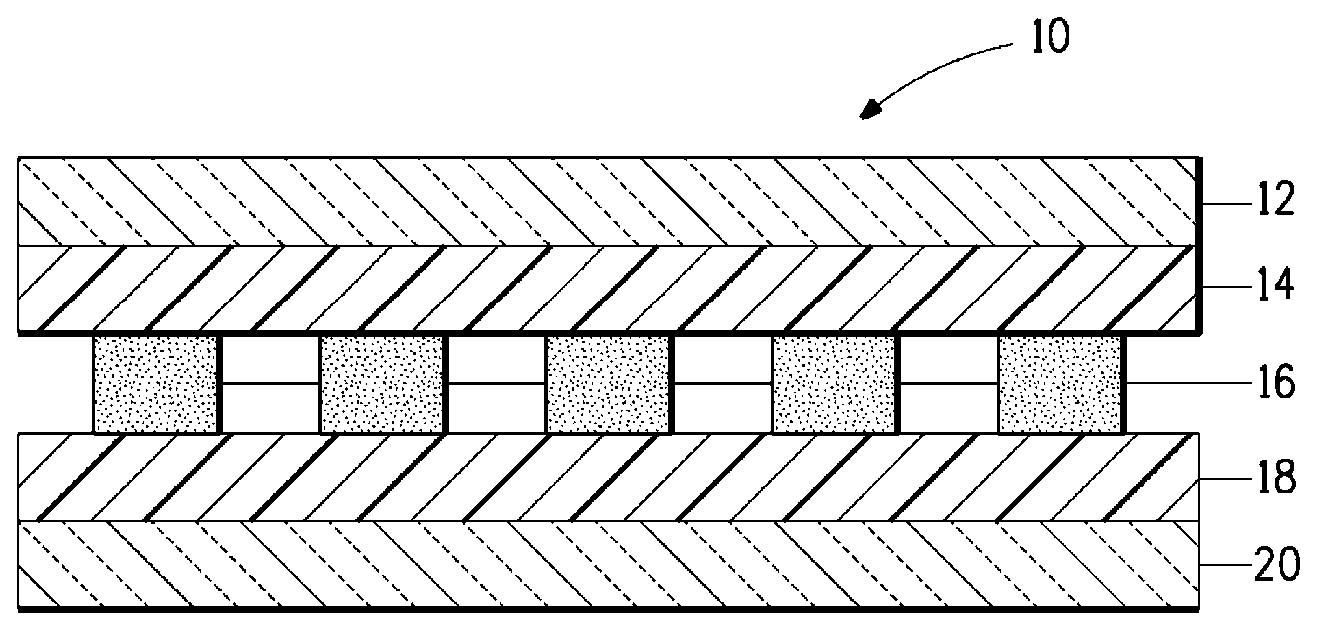

A photovoltaic module and backplane technology, which is applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve the problems of affecting the electrical insulation performance of the backplane and difficult to be permanently attached.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

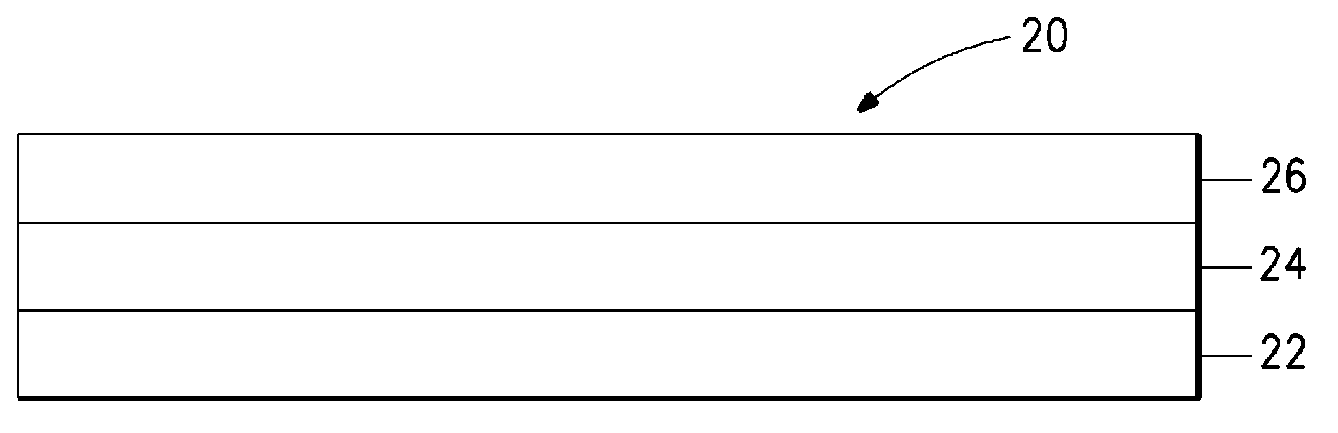

[0069] Flexible mica sheet was obtained from PAMICA Electric Material (Hubei) Co., Ltd. (Xianning, China) under product number PB5161. The mica sheet is composed of 90% by weight of muscovite, based on the weight of the sheet, and the sheet is impregnated with 8% by weight of a high temperature resistant silicone resin. The sheet has an average density of 1.9 g / cm 3 , and the basis weight is about 381g / m 2 . The sheet thickness was 7.9 mils (201 microns).

example 2

[0071] Flexible mica sheet was obtained from PAMICA Electric Material (Hubei) Co., Ltd. (Xianning, China) under product number PJ5161. The mica sheet is composed of 90% by weight of phlogopite mica based on the weight of the sheet, and the sheet is impregnated with 8% by weight of the high temperature resistant silicone resin. The sheet has an average density of 1.9 g / cm 3 And the basis weight is about 381g / m 2 . The sheet thickness was 7.9 mils (201 microns).

example 3

[0073] Flexible glass-backed mica sheet was obtained from PAMICA Electric Material (Hubei) Co., Ltd. (Xianning, China) under product number S140G32. The mica sheet is composed of 90% by weight of mica based on the weight of the sheet, and the sheet is impregnated with 8% by weight of the high temperature resistant silicone resin. Basis weight is about 195g / m 2 . The sheet thickness was 5.8 mils (147 microns).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com