Modified high density polyethylene 3D printing moulding material and preparation method

A high-density polyethylene, 3D printing technology, applied in the field of 3D printing molding materials, can solve the problems of complex nanofiber composite line FDM, low HDPE toughness, low impact strength, etc., and achieve easy industrial production, high tensile strength, good The effect of impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

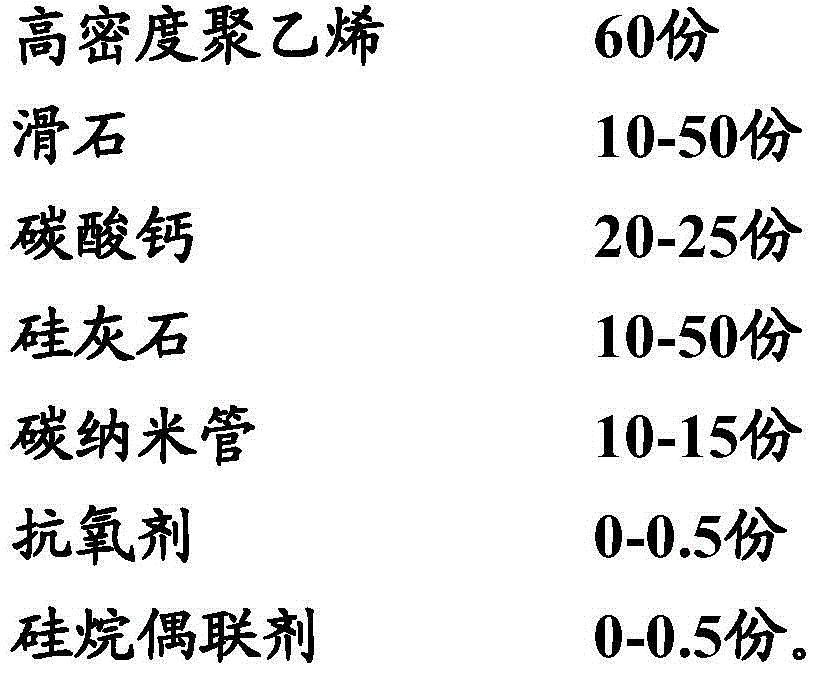

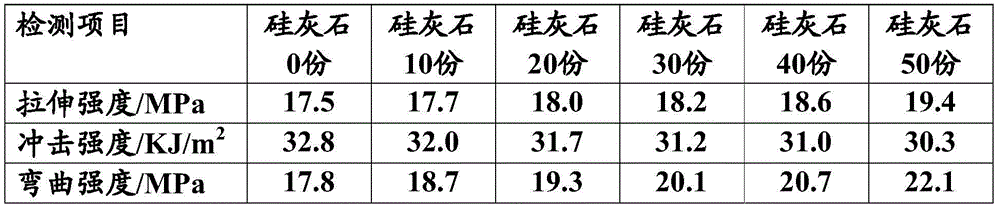

[0030] 60 parts by weight of HDPE, 20 parts of CaCO 3 , 20 parts of wollastonite, 0, 10, 20, 30, 40 or 50 parts of talc, 10 parts of carbon nanotubes, 0.1 parts of antioxidant CA, 0.1 parts of silane coupling agent, mixed by a high-speed mixer 5min, and then extruded and granulated in a twin-screw extruder, and the granules were cooled and dried, and then injection-molded to obtain a sample. Wherein the carbon nanotubes are activated by nitric acid, and the specific process of nitric acid activation is to reflux the carbon nanotubes in 65% concentrated nitric acid for 2 hours, ultrasonically disperse them at the same time, and then wash them with distilled water until neutral.

[0031] Process conditions: ①Extrusion process: extrusion temperature 175°C, screw speed 240r / min. ②Injection process: injection molding temperature 180°C, injection pressure 80MPa; injection speed 40g / s; injection time 6s; dwell time 10s; mold temperature 50°C.

[0032] The main properties of the mod...

Embodiment 2

[0036] 60 parts by weight of HDPE, 20 parts of CaCO 3 , 10 parts of talc, 10 parts of carbon nanotubes, 0.5 parts of antioxidant CA, 0.5 parts of silane coupling agent, and 0, 10, 20, 30, 40 or 50 parts of wollastonite are mixed by a high-speed mixer 5min, and then extruded and granulated in a twin-screw extruder, and the granules were cooled and dried, and then injection-molded to obtain a sample. Wherein the carbon nanotubes are activated by nitric acid, and the specific process of nitric acid activation is to reflux the carbon nanotubes in 65% concentrated nitric acid for 2 hours, ultrasonically disperse them at the same time, and then wash them with distilled water until neutral.

[0037] Process conditions: ①Extrusion process: extrusion temperature 175°C, screw speed 240r / min. ②Injection process: injection molding temperature 180°C, injection pressure 80MPa; injection speed 40g / s; injection time 6s; dwell time 10s; mold temperature 50°C.

[0038] The main properties of ...

Embodiment 3

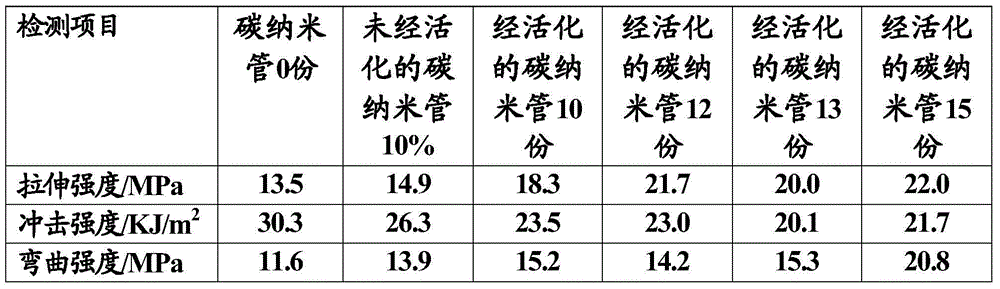

[0042] 60 parts by weight of HDPE, 20 parts of CaCO 3 , 20 parts of talc, 0.1 part of antioxidant CA, 0.1 part of silane coupling agent, 30 parts of wollastonite, 0, 10 (activated by nitric acid), 10 (not activated by nitric acid), 12 (activated by nitric acid ), 13 (activated by nitric acid) and 15 (activated by nitric acid) carbon nanotubes were mixed by a high-speed mixer for 5 minutes, then extruded and granulated by a twin-screw extruder, and the pellets were cooled and dried by injection molding to obtain a sample strip. Wherein the activation of carbon nanotubes is the same as in Examples 1 and 2.

[0043] Process conditions: ①Extrusion process: extrusion temperature 175°C, screw speed 240r / min. ②Injection process: injection molding temperature 180°C, injection pressure 80MPa; injection speed 40g / s; injection time 6s; dwell time 10s; mold temperature 50°C.

[0044] The main properties of the modified HDPE were tested, and the test results are as follows:

[0045] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com