Device and method for automatically rolling and folding dough and leading out flour tapes

A guiding device and rolling technology, applied in the direction of dough sheeting machine/rolling machine/rolling stick, dough extruder, etc., can solve the problems of reducing production efficiency, poor practical performance, and increasing production costs of enterprises, and achieve The effect of improving production efficiency, increasing service life, and increasing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

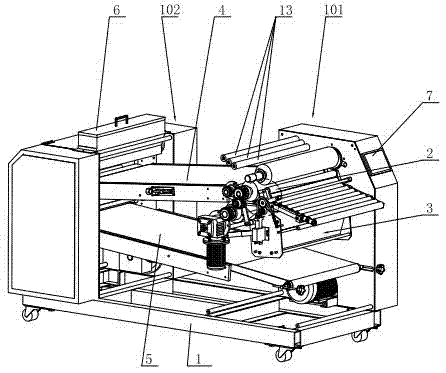

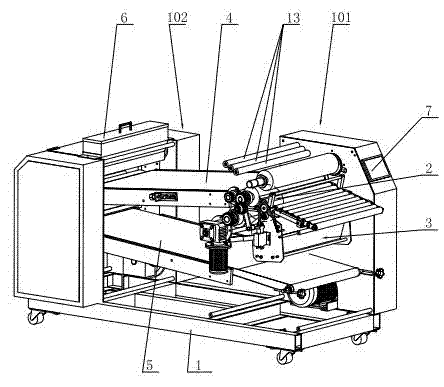

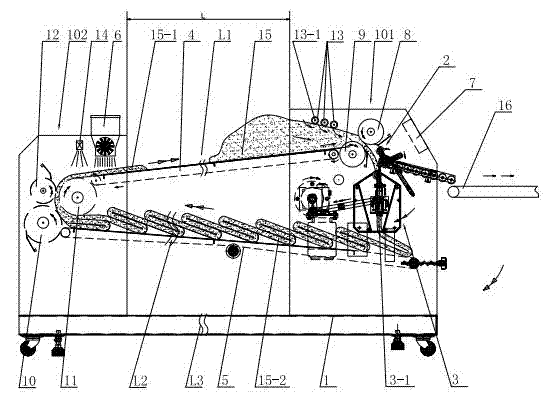

[0047] Such as figure 1 , figure 2 As shown, the present invention includes a machine base 1, a front machine platform 101 and a rear machine platform 102 are installed on the machine base 1, and an upper conveyor belt 4 and a lower conveyor belt 5 are installed between the front machine platform 101 and the rear machine platform 102, as image 3 , Figure 4 As shown, the distance between the front platform 101 and the rear platform 102 is set as L, the length of the upper conveyor 4 is set as L1, the length of the lower conveyor belt 5 is set as L2, and the length of the frame 1 is set as L3; In 101, one end of the upper conveyor belt 4 and the lower conveyor belt 5 is sequentially provided with extruding pulleys, the first pressing roller group, noodle belt guide 2, swinging and folding device 3 and deriving pulleys; The other end de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com