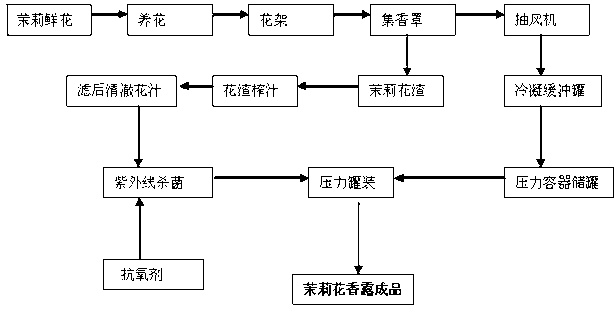

Production method for jasmine flower perfume

A production method, the technology of jasmine, is applied in the formulation of perfume preparations, pharmaceutical formulations, cosmetic preparations, etc., which can solve the problem of high cost and achieve the effect of enriching the food market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) After the picked jasmine flowers are cultivated, they are placed on the flower stand, and the flower stand is moved into the fragrance collection cover;

[0026] (2) Use the exhaust fan to send the flower fragrance in the fragrance collection cover to the condensation buffer tank at 0°C;

[0027] (3) Use a pressure pump to pump the flower aroma in the condensation buffer tank into the pressure vessel storage tank for storage;

[0028] (4) Scald the flower residues that have been smoked in the fragrance collecting hood twice with hot water at 80°C, use 100 kg of pure water for every 100 kilograms of flower residues, and squeeze the flower residues into flower juice with a juicer;

[0029] (5) Squeeze and filter the flower dregs into clear flower juice, and then add 0.1% vitamin C antioxidant relative to the weight of the flower juice after ultraviolet sterilization;

[0030] (6) Put the 15ml flower juice tank of (5) into a 100ml pressure packaging tank, and then put...

Embodiment 2

[0032] (1) After the picked jasmine flowers are cultivated, they are placed on the flower stand, and the flower stand is moved into the fragrance collection cover;

[0033] (2) Use the exhaust fan to send the flower fragrance in the fragrance collection cover to the condensation buffer tank at 8°C;

[0034] (3) Use a pressure pump to pump the flower aroma in the condensation buffer tank into the pressure vessel storage tank for storage;

[0035] (4) Blanch the flower dregs that have been smoked in the fragrance collecting hood twice with hot water at 90°C, and squeeze the flower dregs into flower juice with a juicer; use 300 kg of pure water for every 100 kg of flower dregs

[0036] (5) Squeeze and filter the flower dregs into clear flower juice, then add 1.0% vitamin C antioxidant relative to the weight of the flower juice after ultraviolet sterilization;

[0037] (6) Put the 43ml flower juice tank of (5) into a 100ml pressure packaging tank, and then put the flower aroma in...

Embodiment 3

[0039] (1) After the picked jasmine flowers are cultivated, they are placed on the flower stand, and the flower stand is moved into the fragrance collection cover;

[0040] (2) Use the exhaust fan to send the flower fragrance in the fragrance collection cover to the condensation buffer tank at 15°C;

[0041] (3) Use a pressure pump to pump the flower aroma in the condensation buffer tank into the pressure vessel storage tank for storage;

[0042] (4) Use 100°C hot water twice for the flower residues that have been smoked in the fragrance collecting hood, and squeeze the flower residues into flower juice with a juicer; use 500 kg of purified water for every 100 kg of flower residues

[0043] (5) Squeeze and filter the flower dregs into clear flower juice, then add 2.0% vitamin C antioxidant relative to the weight of the flower juice after ultraviolet sterilization;

[0044] (6) Put the 80ml flower juice tank of (5) into a 100ml pressure packaging tank, and then put the flower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com