Thermal compression bonding power source

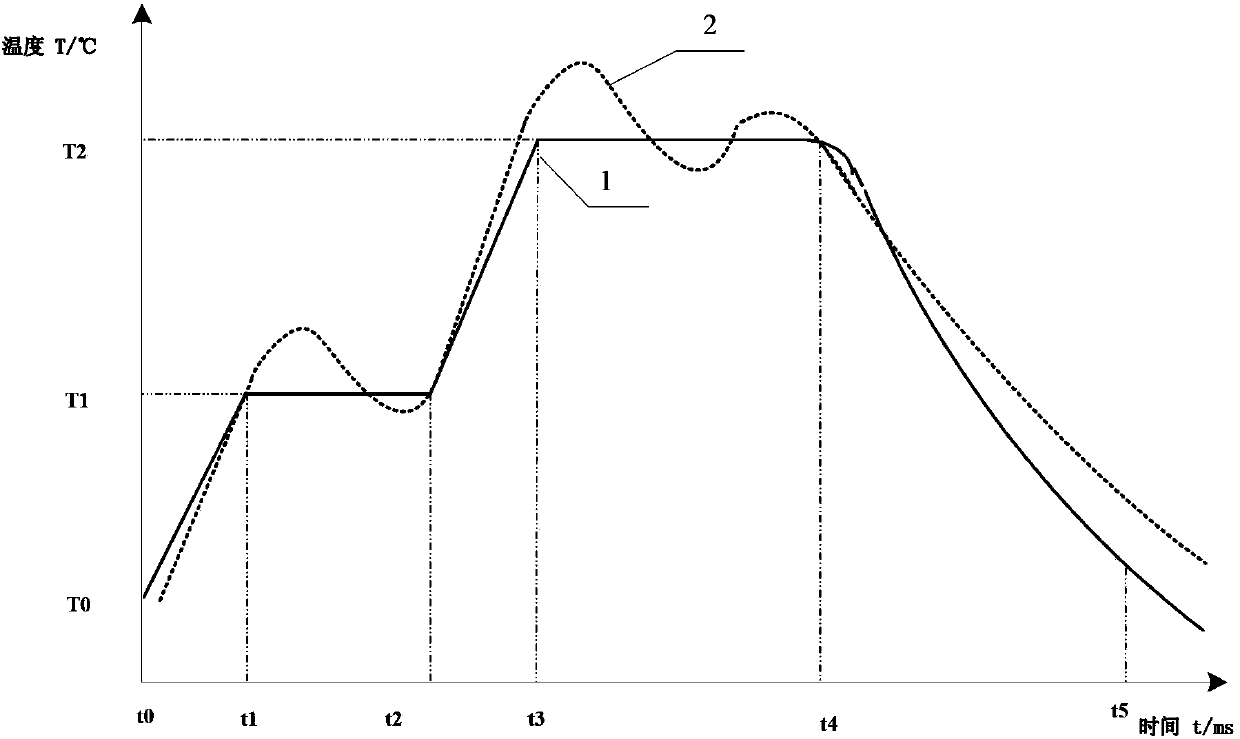

A technology of hot-press welding and hot-press welding head, which is applied in the field of hot-press welding, can solve problems such as control errors, large fluctuations in temperature control waveforms, and temperature overshoot, and achieve the effects of improving stability and avoiding temperature overshoot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

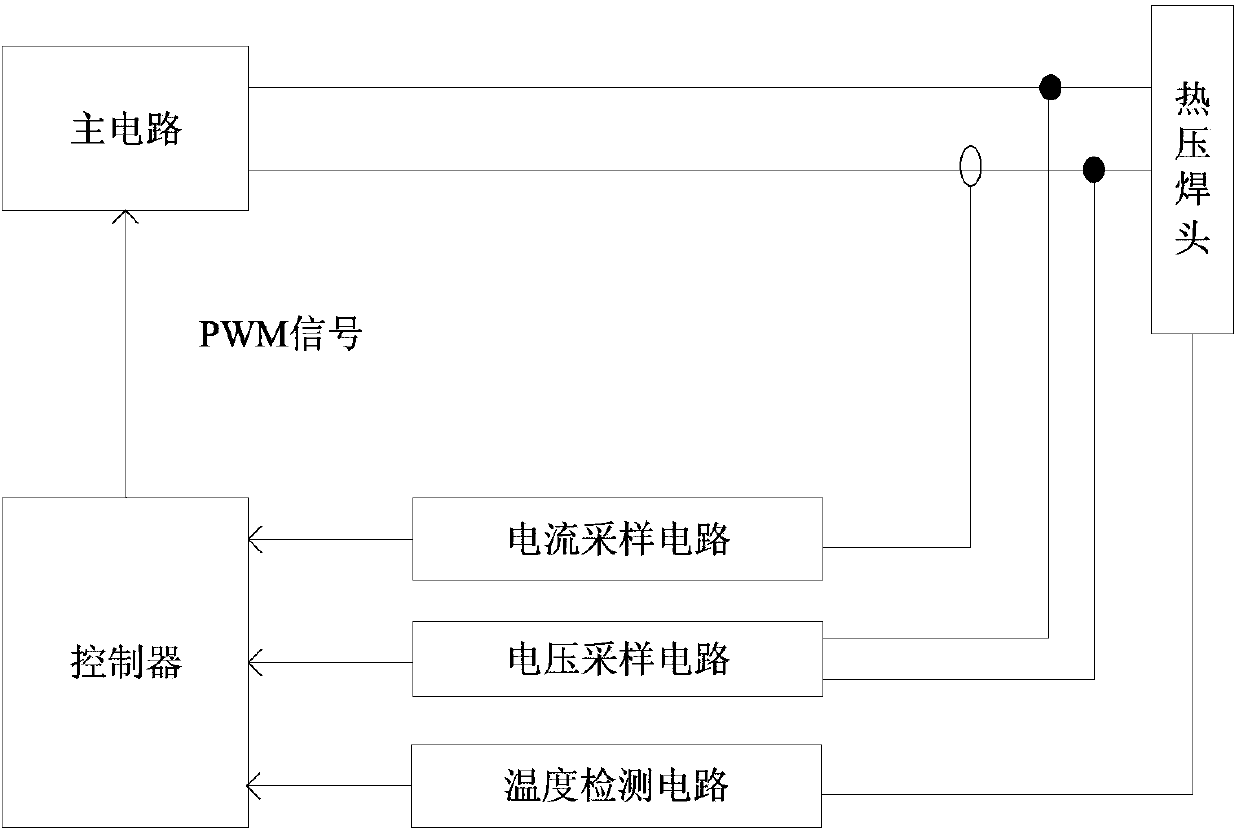

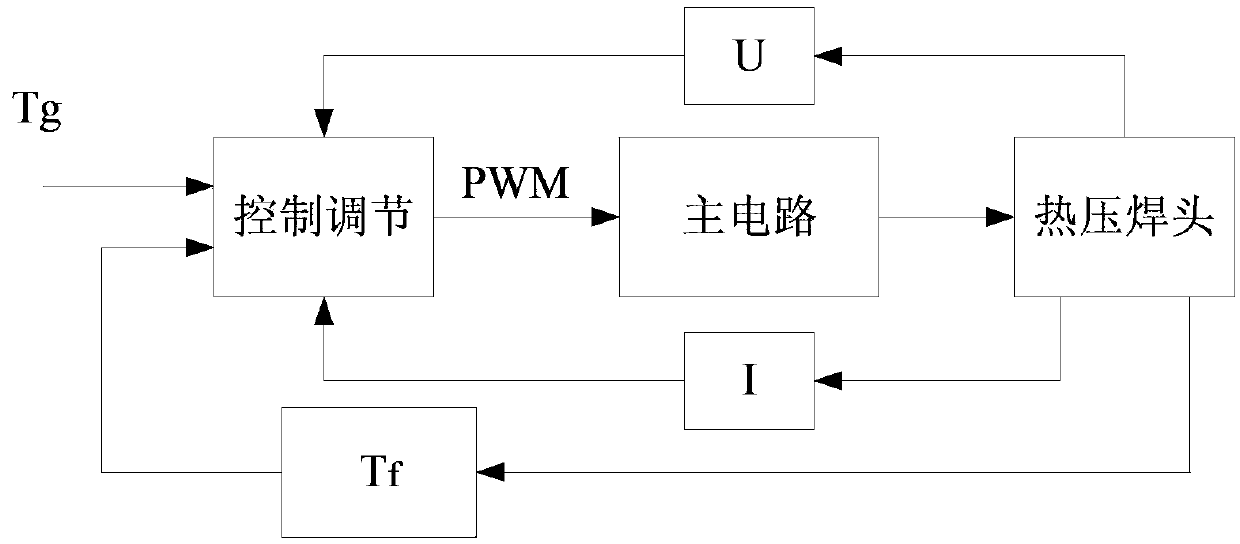

[0031] The specific implementation of the heat-compression welding power source of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0032] figure 2 It shows a schematic structural diagram of a thermocompression welding power source of an embodiment, including: a main circuit for outputting direct current / pulse current to a thermocompression welding head, a controller, and current sampling circuits respectively connected to the thermocompression welding heads , voltage sampling circuit and temperature detection circuit.

[0033] The main circuit adjusts the output current of the main circuit according to the PWM signal output by the controller.

[0034] The current sampling circuit collects the output current of the main circuit to obtain a feedback current value and outputs it to the controller.

[0035] The voltage sampling circuit collects the voltage at both ends of the thermocompression welding head to obtain a fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com