Environment-friendly novel method for preparing primary alcohol from furan or tetrahydrofuran derivatives

A technology of tetrahydrofuran and derivatives, applied in the field of catalytic chemistry, can solve the problems of expensive ionic liquids, high production costs, and complicated separation, and achieve good industrial prospects, reduce separation costs, and facilitate separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

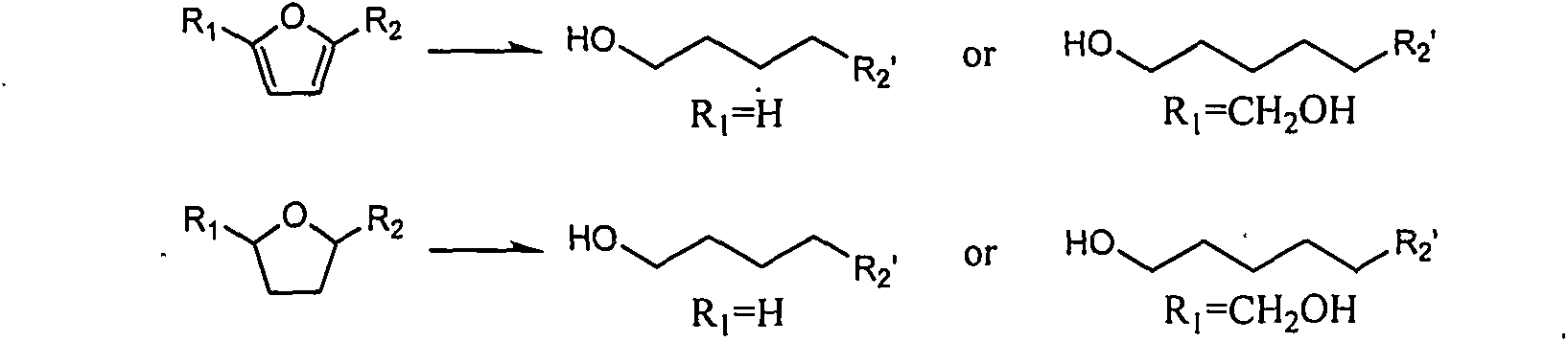

Method used

Image

Examples

Embodiment 1-10

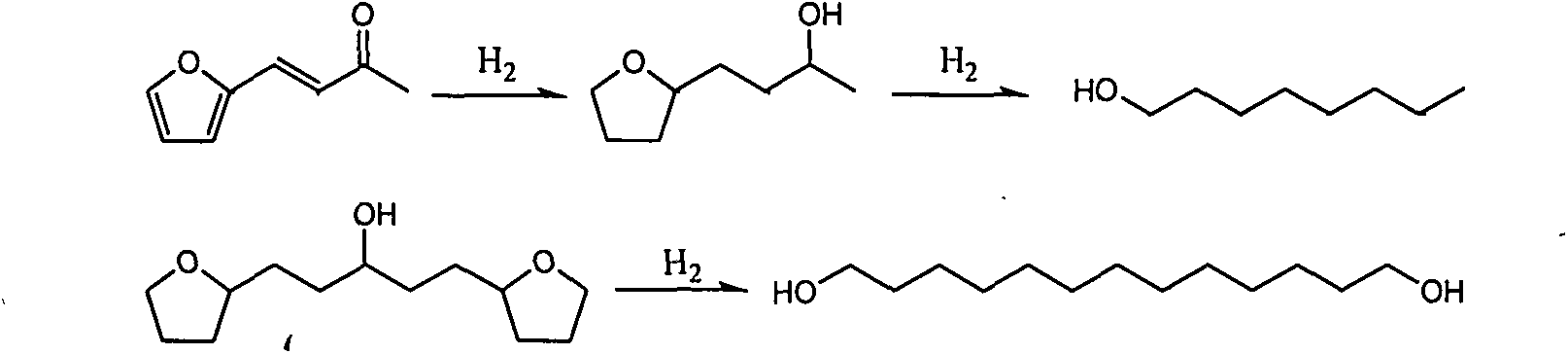

[0013] Examples 1-10 use the multifunctional catalyst Pd / H-ZSM-5 to catalyze different reaction substrates and react under different reaction conditions. The reaction substrates and corresponding primary alcohols are shown in Table 1.

[0014] Table 1

[0015] Example

Five-membered heterocycle

R1

R2

R 2 ′

Example 1

-H

-CHO

-CH 3

Example 2

-H

-CH=CHCOCH 3

-CH 2 CH 2 CH 2 CH 3

Example 3

-H

-CH 2 COHCH 3

-CH 2 CH 2 CH 3

Example 4

-H

-CH 2 CH 3

-CH 2 CH 3

Example 5

-H

-CH=CHCOCH=CH-C 4 H 3 O

-(CH 2 ) 9 -OH

Example 6

Furan

-CH 2 OH

-CHO

-CH 3

Example 7

-CH 2 OH

-CH 2 CH 2 COOH

-CH 2 CH 2 CH 3

Example 8

Tetrahydrofuran

-CH 2 OH

-CH 2 CH 2 -C 6 H 5

-CH 2 CH 2 -C 6 H 11

Example 9

Furan

-CH 2 OH

-CH 2 CH 2 Cl

-CH 2 CH 2 Cl

Example 10

Tetrahydrofuran

-CH 2 OH

-CH 2 COOCH 3

-CH 2 CH 3

[0016] Example 1-10 reaction conditions and reaction results are shown in Table 2

[0...

Embodiment 11-20

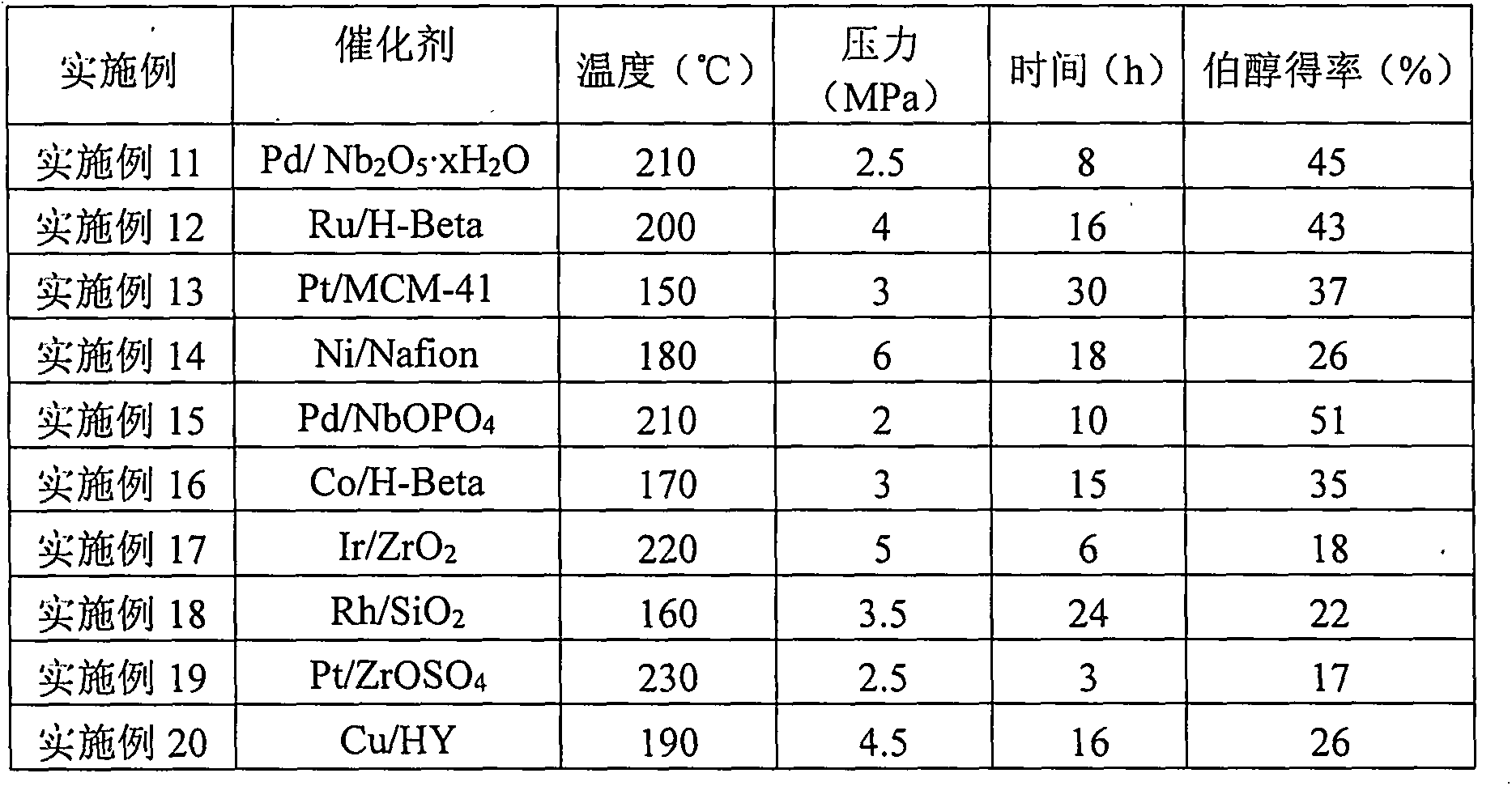

[0020] Examples 11-20 select 4-(2-furyl)-3-buten-2-one as the substrate, select different multifunctional catalysts to catalyze, and react under different conditions. The reaction results are shown in Table 3.

[0021] table 3

[0022]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com