Preparation method for water-repellent oil-repellent flame-retardant protective suit fabric

A protective clothing and hydrophobic technology, which is applied in the preparation of flame-retardant protective clothing fabrics, hydrophobic and oil-repellent fields, can solve the problems of high price, unstable physical properties, and poor light resistance of aramid 1313, and achieve superior hydrophobic and oil-repellent effects , surface roughness and hydrophobic and oleophobic effect increase, the effect of superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

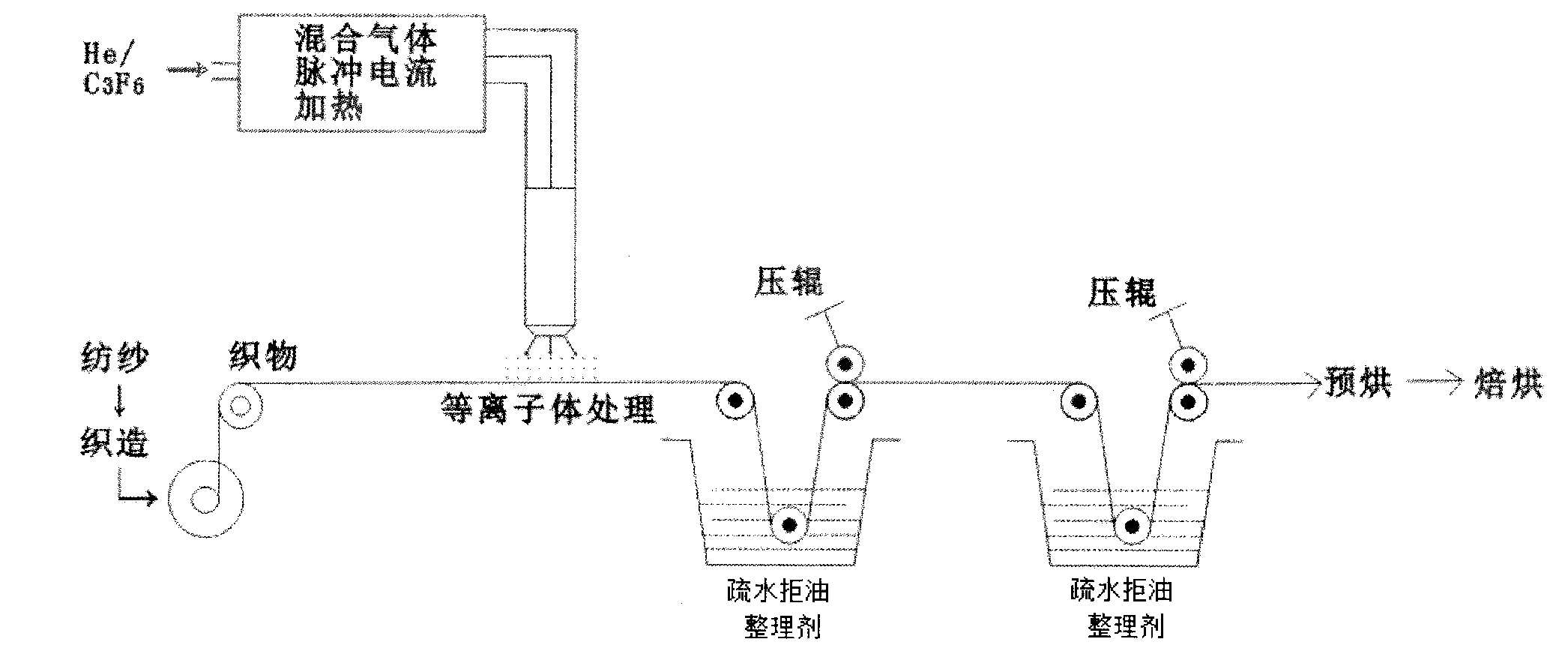

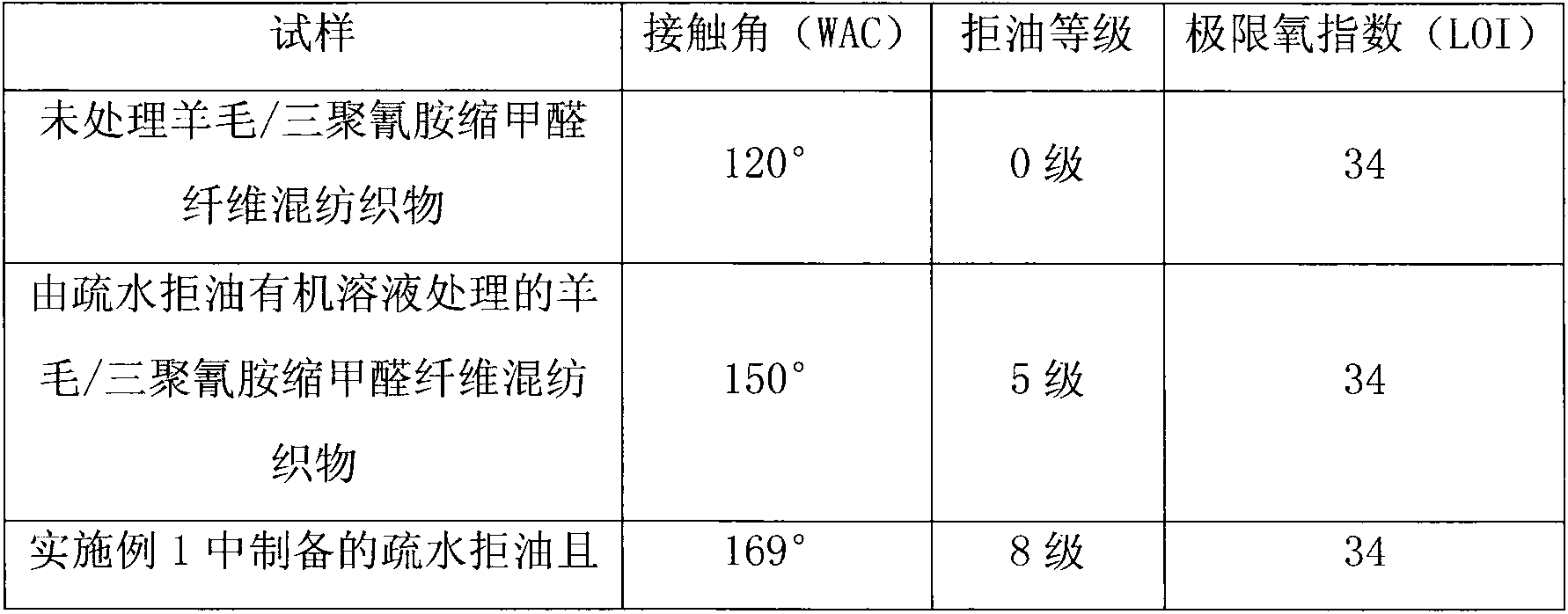

[0025] Such as figure 1 As shown, it is a diagram of the preparation process of the hydrophobic, oil-repellent and flame-retardant protective clothing fabric. The specific steps of the preparation method of the hydrophobic, oil-repellent and flame-retardant protective clothing fabric are as follows:

[0026] The blended yarn of wool and melamine formal fiber is woven into high-count and high-density poplin structural fabric, the blending ratio of wool and melamine formal fiber in the blended yarn of wool and melamine formal fiber is 50:50, and the blending ratio is 50:50. The fineness of spinning is 60 pounds, and the twist coefficient is 330. The warp fineness of the high-count and high-density poplin structure fabric is 60 pounds, the weft fineness is 60 pounds, and the warp density is 520 / 10cm. The weft yarn density is 310 / 10cm, and the fabric tightness is 87%.

[0027] The fabric is subjected to hydrophobic and oil-repellent finishing, and the hydrophobic and oil-repellen...

Embodiment 2

[0032] Such as figure 1 As shown, it is a diagram of the preparation process of the hydrophobic, oil-repellent and flame-retardant protective clothing fabric. The specific steps of the preparation method of the hydrophobic, oil-repellent and flame-retardant protective clothing fabric are as follows:

[0033]The blended yarn of wool and melamine formal fiber is woven into high-count and high-density poplin structural fabric, and the blending ratio of wool and melamine formal fiber in the blended yarn of wool and melamine formal fiber is 50:50, The fineness of the blended yarn is 60 pounds, and the twist coefficient is 330. The warp fineness of the high-count and high-density poplin structure fabric is 60 pounds, the weft fineness is 60 pounds, and the warp density is 520 / 10cm , the weft density is 310 / 10cm, and the fabric tightness is 87%.

[0034] The fabric is subjected to hydrophobic and oil-repellent finishing, and the hydrophobic and oil-repellent finishing includes: fi...

Embodiment 3

[0039] Such as figure 1 As shown, it is a diagram of the preparation process of the hydrophobic, oil-repellent and flame-retardant protective clothing fabric. The specific steps of the preparation method of the hydrophobic, oil-repellent and flame-retardant protective clothing fabric are as follows:

[0040] The blended yarn of wool and melamine formal fiber is woven into high-count and high-density poplin structural fabric, the blending ratio of wool and melamine formal fiber in the blended yarn of wool and melamine formal fiber is 60:40, and the blending ratio of wool and melamine formal fiber is 60:40. The fineness of spinning is 80 pounds, and the twist coefficient is 350. The warp fineness of the high-count and high-density poplin structure fabric is 80 pounds, the weft fineness is 80 pounds, and the warp density is 530 / 10cm. The weft density is 320 / 10cm, and the fabric tightness is 89%.

[0041] The fabric is subjected to hydrophobic and oil-repellent finishing, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| twist factor | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| twist factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com