Recycled constant-temperature ceramic floor integrated system

An integrated system and floor technology, applied in the field of building materials, can solve the problems of inability to erect heat pipes, poor heat source supply, and large on-site construction volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

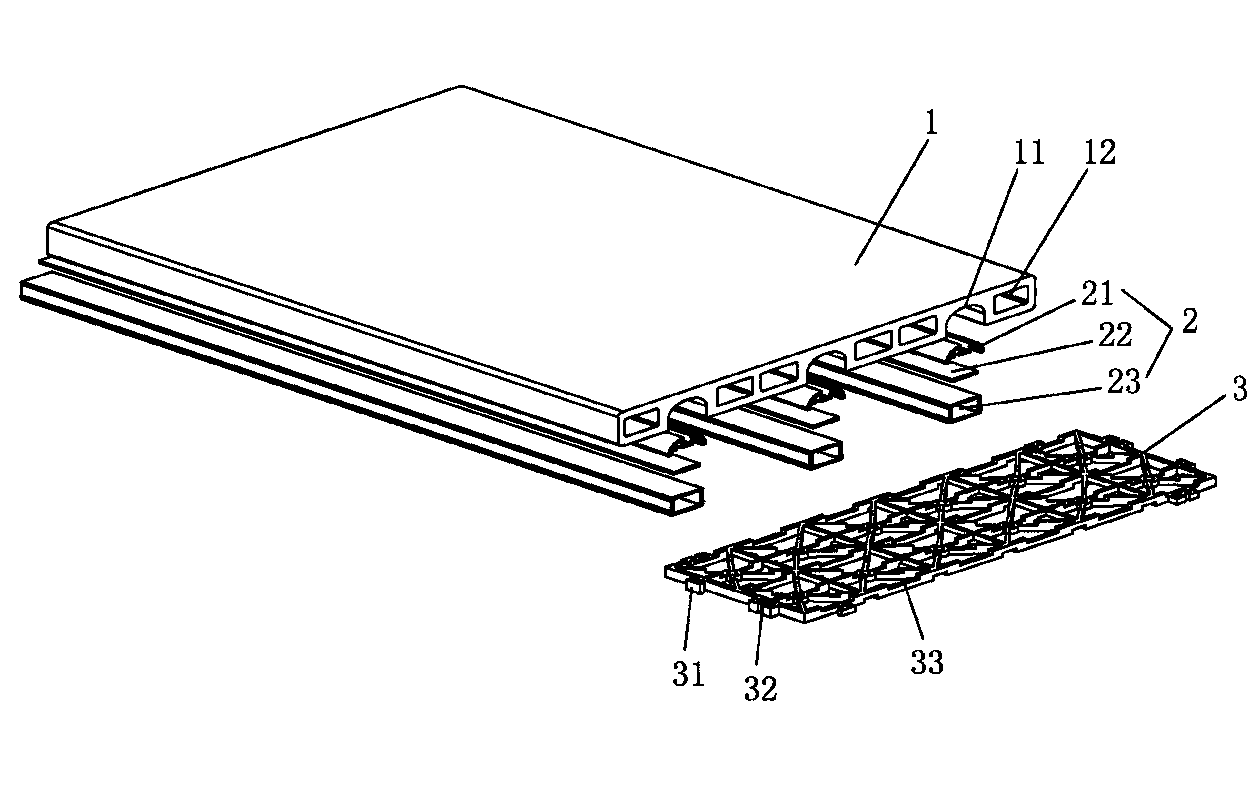

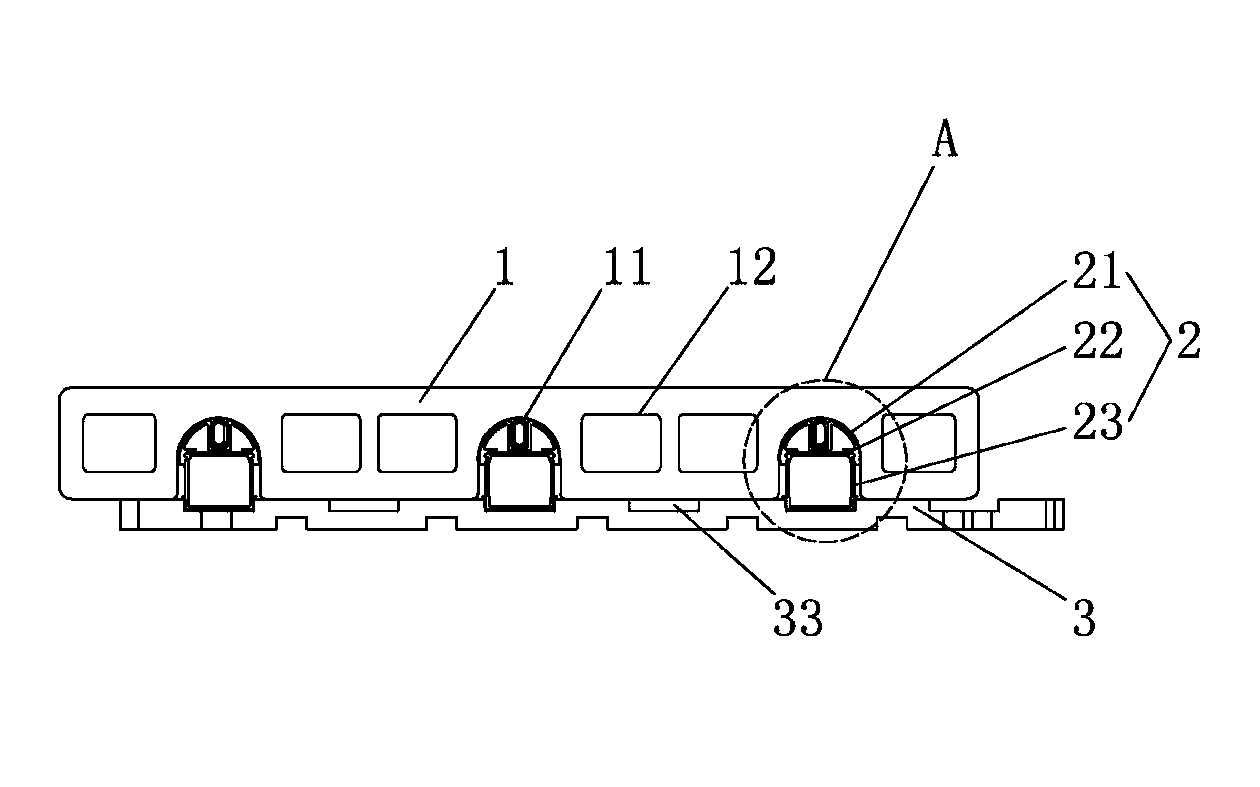

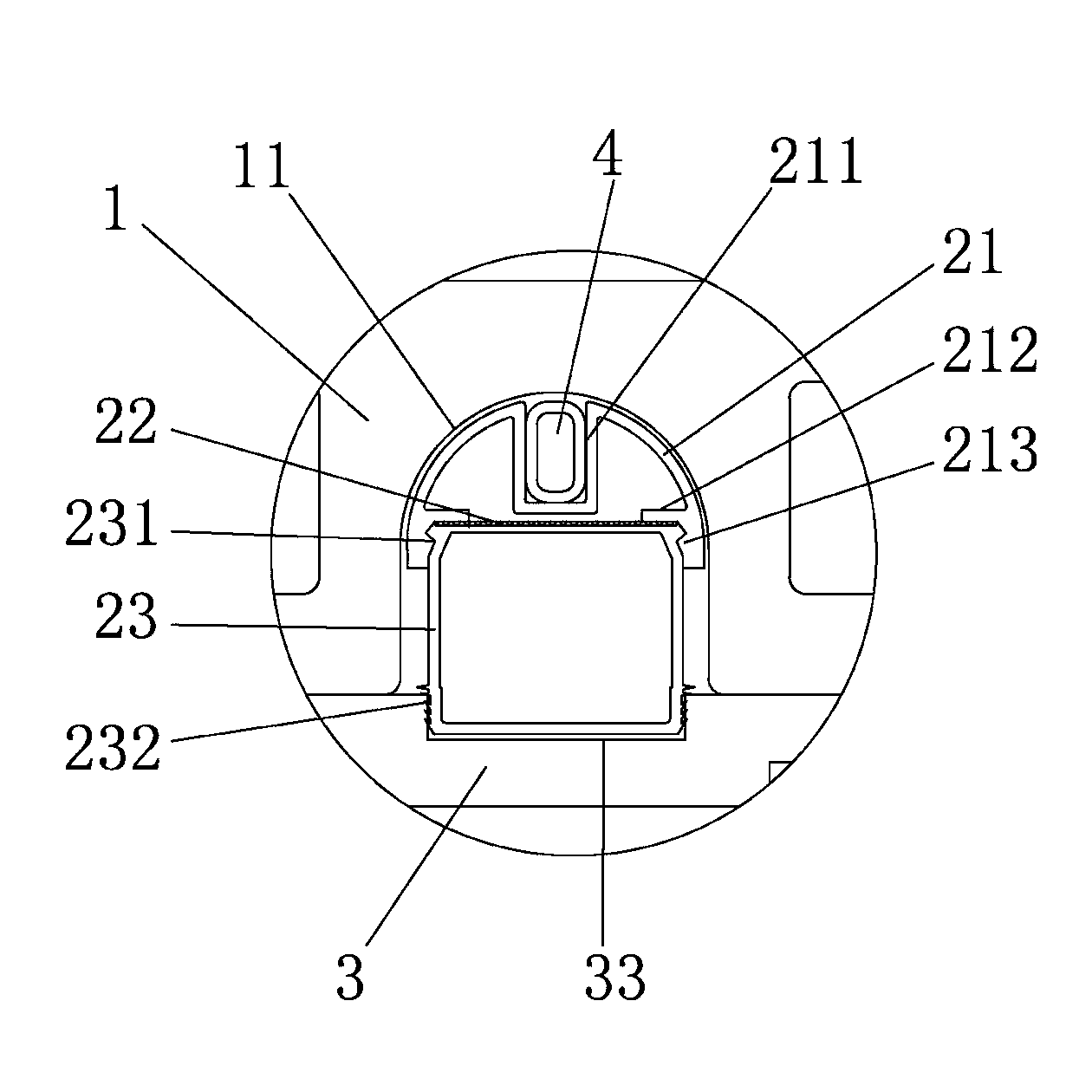

[0023] Such as figure 1 , figure 2 As shown, this embodiment 1 adopts the floor integrated system of the electric heating device, including the floor tile 1, and there are several grooves 11 arranged in parallel at intervals on the bottom surface of the floor tile 1, and the cross-sectional shape of the groove 11 is "U" shape The middle part of the floor tile 1 is also provided with several square hollow holes 12, which effectively reduce the weight and save the use of materials. The bottom surface of the floor tile 1 is connected with a substrate 3, and all lay There is a bracket assembly 2, and the bracket assembly 2 includes a heat conduction element 21 and a positioning bracket 23 that are built up and down. A reflective film 22 is provided between the heat-conducting member 21 and the positioning bracket 23. The reflective film 22 can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com