System and method for checking and accepting quality of precast concrete component

A prefabricated concrete and component technology, applied in computer parts, instruments, data processing applications, etc., can solve problems such as human error, lack of effective means for inspectors to complete quality, deliberate fabrication, etc., to achieve enhanced control and good portability. and reusability, the effect of ensuring effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

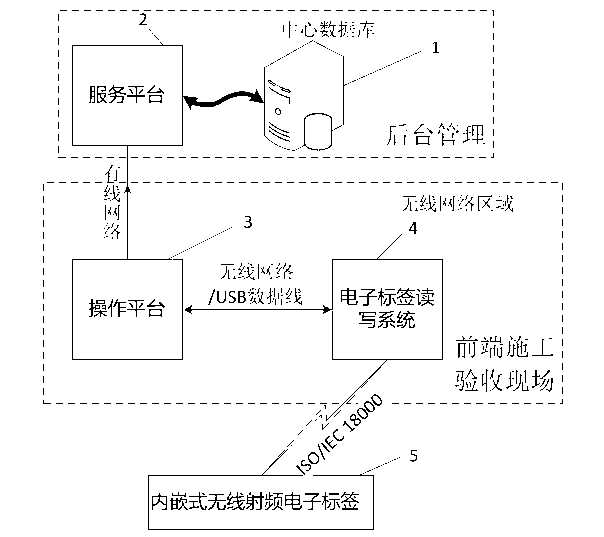

[0017] see figure 1 , the quality acceptance system of precast concrete components, including embedded radio frequency electronic tags (5), UHF electronic tag reading and writing system (4), front-end operating platform (3) and background with central database (1) The service platform (2) is characterized in that: the UHF electronic tag reading and writing system (4) communicates with the embedded radio frequency electronic tag (5) in accordance with the ISO / IEC 18000 protocol, through a USB data line or a wireless network Interact data with the operation platform (3), the operation platform (3) exchanges data with the service platform (2) via the wired network, the service platform (2) is connected with the central database (1), and the system data is stored in the central database (1).

Embodiment 2

[0019] This embodiment is basically the same as Embodiment 1, and the special features are as follows:

[0020] The UHF electronic tag reading and writing system (4) adopts the UHF electronic tag reading and writing system based on a tablet computer with Chinese patent application number 201210325629.4, and includes an acceptance module: the "PC component quality acceptance management software" installed on the tablet computer "Realize the acceptance function. The operating platform (3) includes a group of computers installed with "PC component quality interactive software", which is any type of personal computer or microcomputer.

Embodiment 3

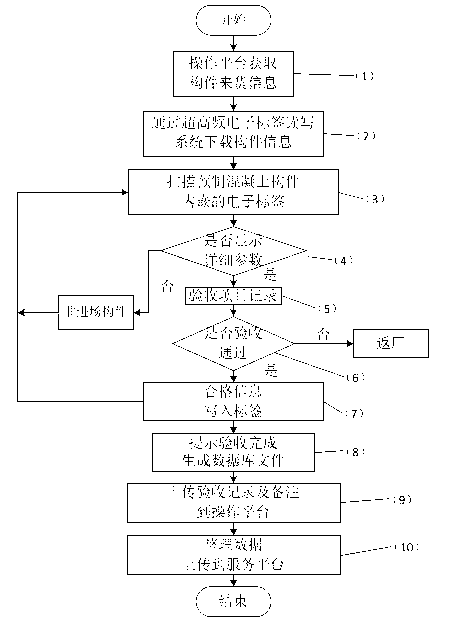

[0022] see figure 2 , the quality acceptance method of precast concrete components, using the above-mentioned system to operate, is characterized in that:

[0023] The operation steps are as follows:

[0024] (1) Download from the background service platform, and obtain the component information of the incoming goods through the operating platform computer;

[0025] (2) Through the wireless network or USB data cable, the UHF electronic tag reading and writing system loads the component information into the tablet computer;

[0026] (3) Use the UHF electronic tag reading and writing system to scan the electronic tags in the precast concrete components to be accepted;

[0027] (4) The system judges whether it is a component to be accepted according to the scanning result, and if it passes, it will display the corresponding position and weight of the component, and provide the drawing viewing function;

[0028] (5) Perform component acceptance according to the accept...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com