Double-fed type wind generating set low-voltage-ride-through control method based on electromagnetic transient algorithm

A wind turbine, low voltage ride-through technology, applied in motor generator control, electronic commutation motor control, wind power generation, etc., can solve the problem that the transient voltage at the rotor end of the doubly-fed motor cannot be reduced to a minimum, and the transient voltage exceeds the voltage. Controllable range, out of control of double-fed wind turbines, etc., to achieve the effect of convenient software upgrade, expansion of fault range, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

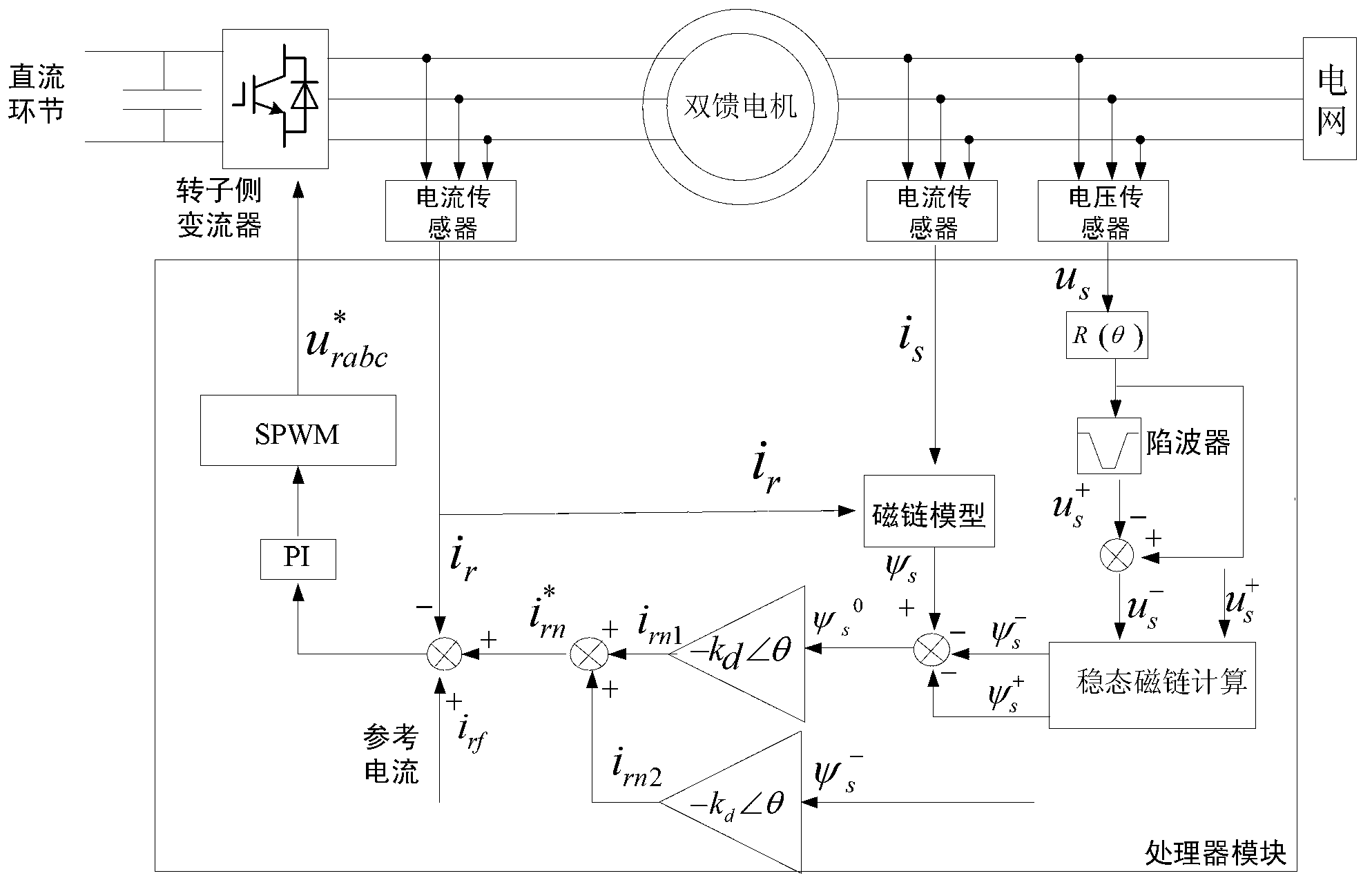

[0048] see figure 1 , the DFIG in this embodiment includes: a DC link, a rotor-side converter, a DFIG, a power grid, a voltage sensor, a current sensor and a processor module. The basic working principle of the DFIG is as follows: : The processor module realizes the control of the rotor-side converter by modulating the control signal, and then the rotor-side converter inverts the DC voltage into three-phase AC current and injects it into the rotor side of the doubly-fed motor to realize the control of the doubly-fed motor, then The stator of the doubly-fed generator directly connected to the grid transmits power to the grid; a low-voltage ride-through control method for a doubly-fed wind turbine based on an electromagnetic transient algorithm is performed as follows:

[0049] Step 1: When the grid voltage falls and the fault occurs, the Hall voltage sensor and the Hall current sensor respectively detect the three-phase voltage u of the stator of the doubly-fed motor. s , stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com