Air filtering membrane and preparation method thereof

A technology of air filtration and organic film, applied in separation methods, chemical instruments and methods, membrane technology, etc., can solve the problems that air filtration devices cannot meet the filtering effect and ventilation effect at the same time, and achieve easy installation, convenient portability, and chemical performance stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

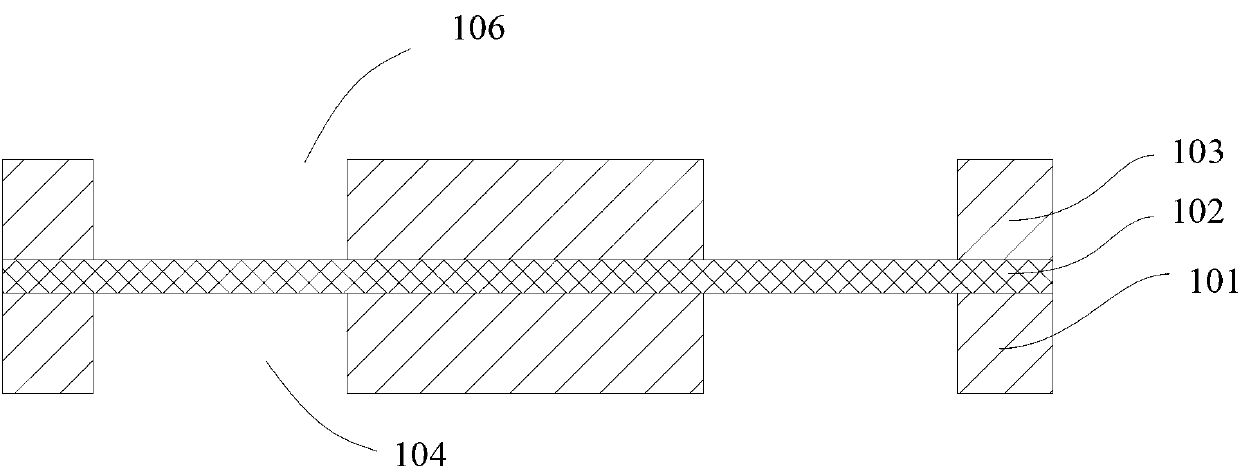

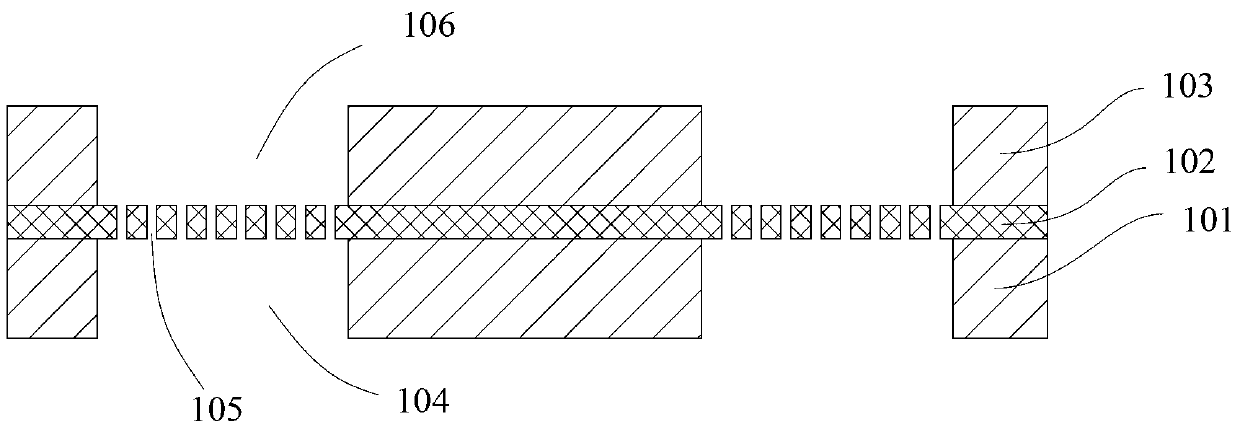

[0078] In the air filtration membrane of the present invention, when the graphene film (102) corresponding to each channel formed by the first through hole (104) and the second through hole (106) is provided with a plurality of third through holes (105) , the preparation method of the air filtration membrane comprises the following steps:

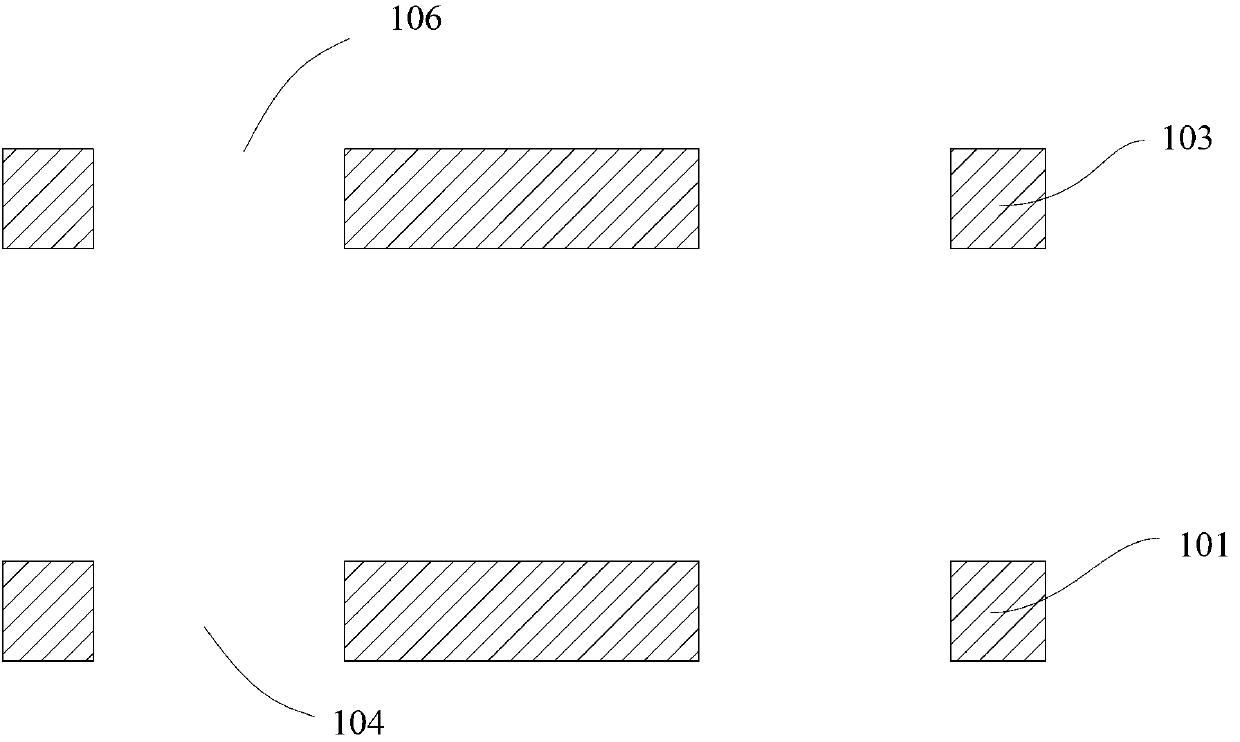

[0079] (1) Provide two transparent films, and laser-etch through holes at corresponding positions to obtain a first transparent organic film 101 with a number of first through holes 104, and a second transparent organic film with the same number of second through holes 106. Organic thin film 103; the structure obtained in step (1) is as follows figure 2 ( figure 2 It is shown in the schematic cross-sectional view of the structure obtained in step (1) of the present invention;

[0080] Wherein, the shape of the first through hole and the second through hole is not specifically limited in the present invention, and may be a circle, an ell...

Embodiment 1

[0087] An air filtration membrane comprising:

[0088] (i) The first transparent organic thin film 101 and the second transparent organic thin film 103, the first transparent organic thin film 101 and the second transparent organic thin film 103 are superimposed together, and the first transparent organic thin film 101 is drawn out by a laser A plurality of first through holes 104, the same number of second through holes 106 are opened on the second transparent organic film 103 by laser, the diameters and positions of the first through holes 104 and the corresponding second through holes 106 are consistent to form a plurality of second through holes 106. channel;

[0089] Wherein, the diameter and position of the first through hole 104 and the corresponding second through hole are the same, and the diameter is 10-30 μm; the first through hole 104 and the second through hole are circular holes;

[0090] The material of the first transparent organic film and the second transpar...

Embodiment 2

[0095] An air filtration membrane, the layered structure is the same as that of Embodiment 1, only the shape of the first through hole and the second through hole are elongated, such as Figure 5 shown ( Figure 5 It is a schematic view of the front structure of the air filtration membrane described in Example 2 of the present invention).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com