Machining method for female die with stepped holes

A processing method and step hole technology, which is applied in the field of mold manufacturing, can solve the problems that the diameter d and depth of large step holes are difficult to control, and the dimensional accuracy of step holes is high, so as to achieve the effect of ensuring size, uniform structure and reducing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

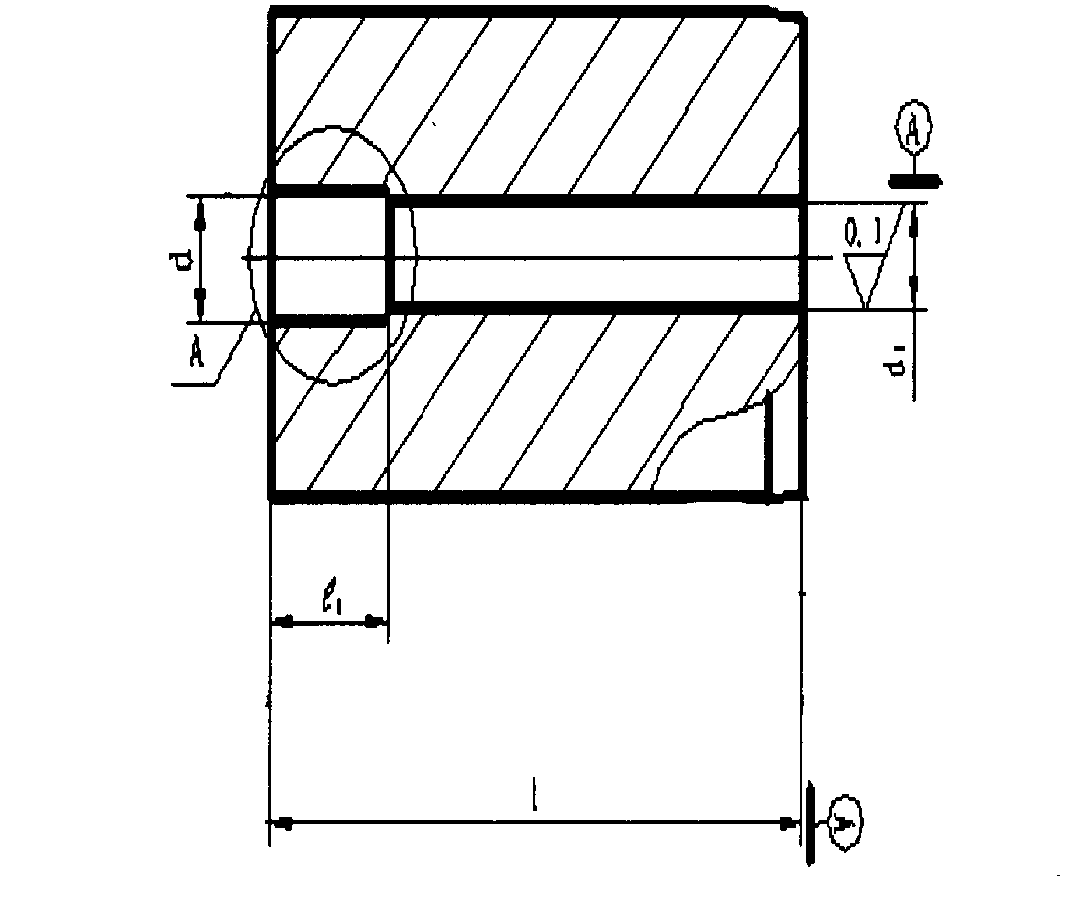

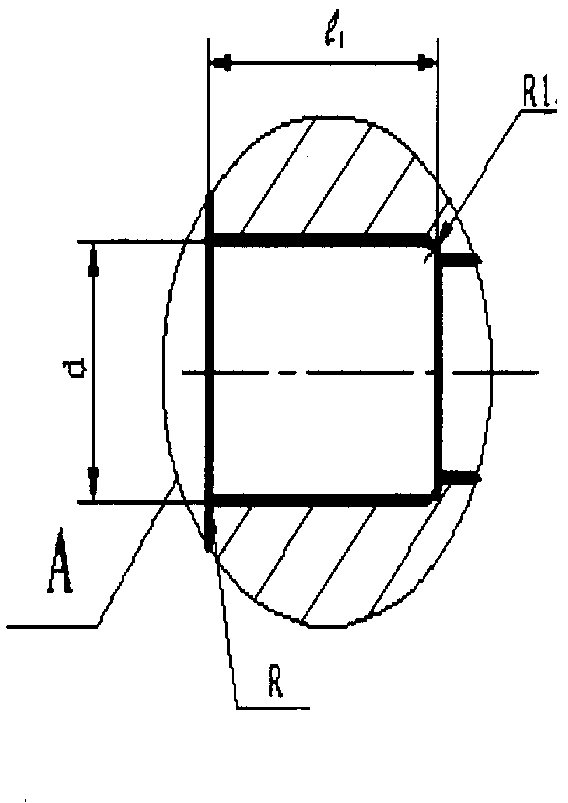

[0023] A step hole female mold, such as figure 1 and figure 2 Shown, its processing method comprises the following specific steps:

[0024] (1) Forging blanking;

[0025] (2) Leave 2mm for the outer circle and 2mm for the length of the rough car;

[0026] (3) Quenching and tempering treatment;

[0027] (4) Sand blowing;

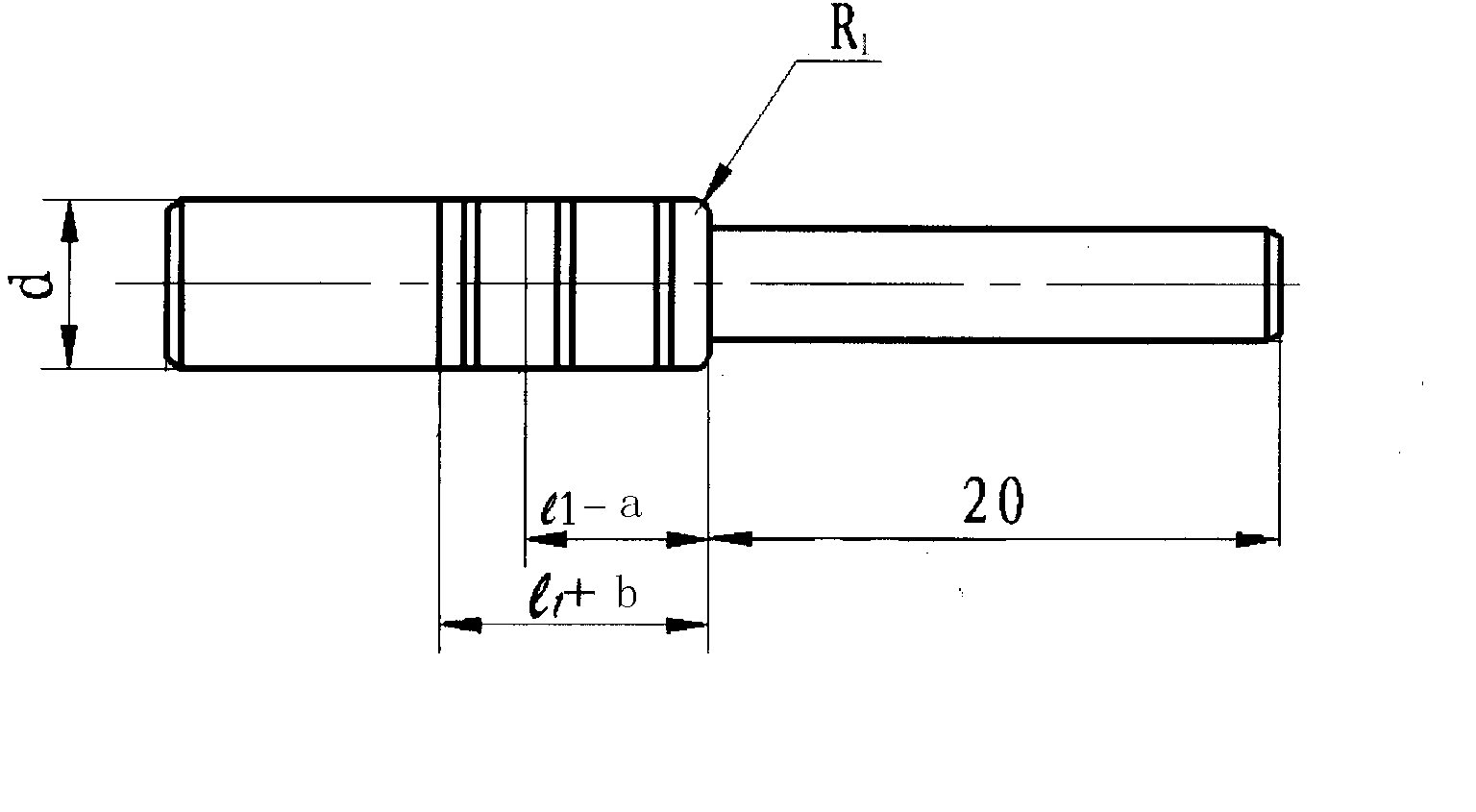

[0028] (5) Rough turning: leave a machining allowance of 0.6mm for the outer circle of the workpiece and both ends, and drill and ream the inner hole first 1 Leave a research amount of 0.04mm, and then use a 1 The blind hole reamer drills and reams the inner hole d, so that the inner hole d leaves a research amount of 0.04mm, R 1 Leave a research amount of 0.04mm;

[0029] (6) Finishing machining: use the inner hole to align the outer circle and flat end surface of the car, and control the verticality and parallelism of the two stepped holes within the required range;

[0030] (7) heat treatment;

[0031] (8) Fitter: Finely grind the inner hole and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com