Material distributing method and device of micro powder carving of polished tile

A technology for distributing devices and polishing tiles, which can be used in engraving, supplying devices, decorative arts, etc., which can solve the problems of increasing power consumption for polishing, increasing the cutting amount of cold processing, and wasting resources, achieving clear line edges, reducing cutting amount, and reducing The effect of production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

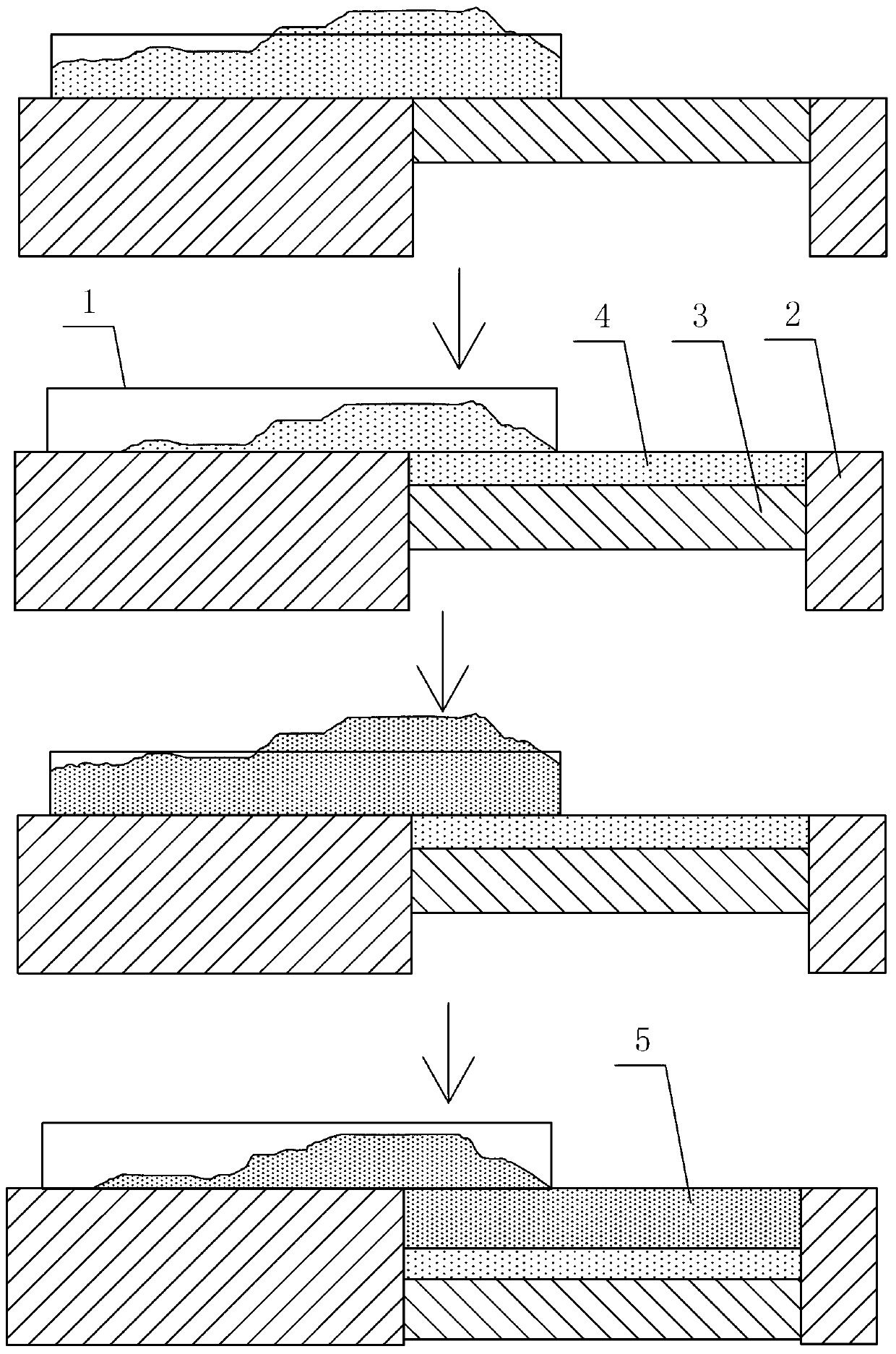

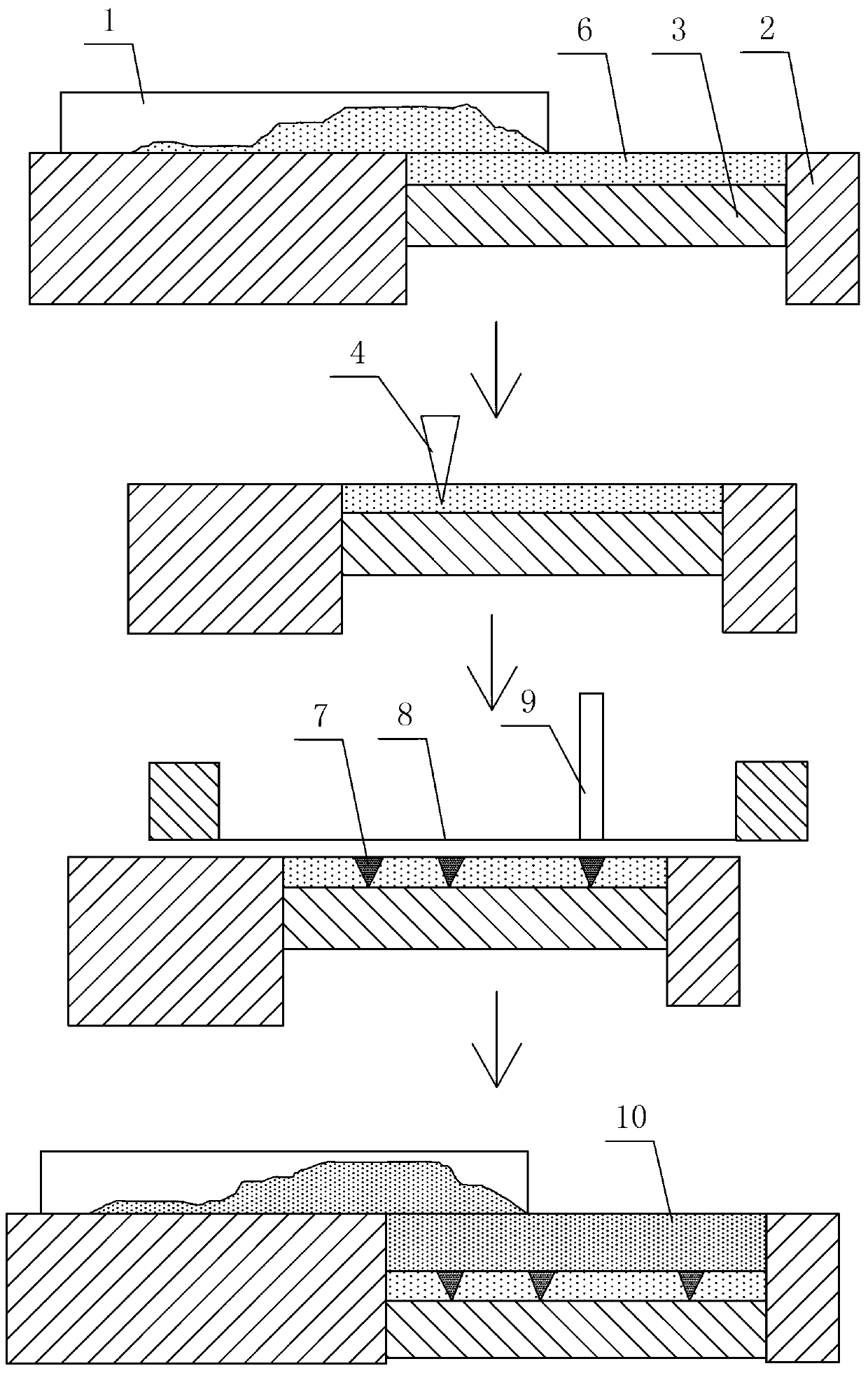

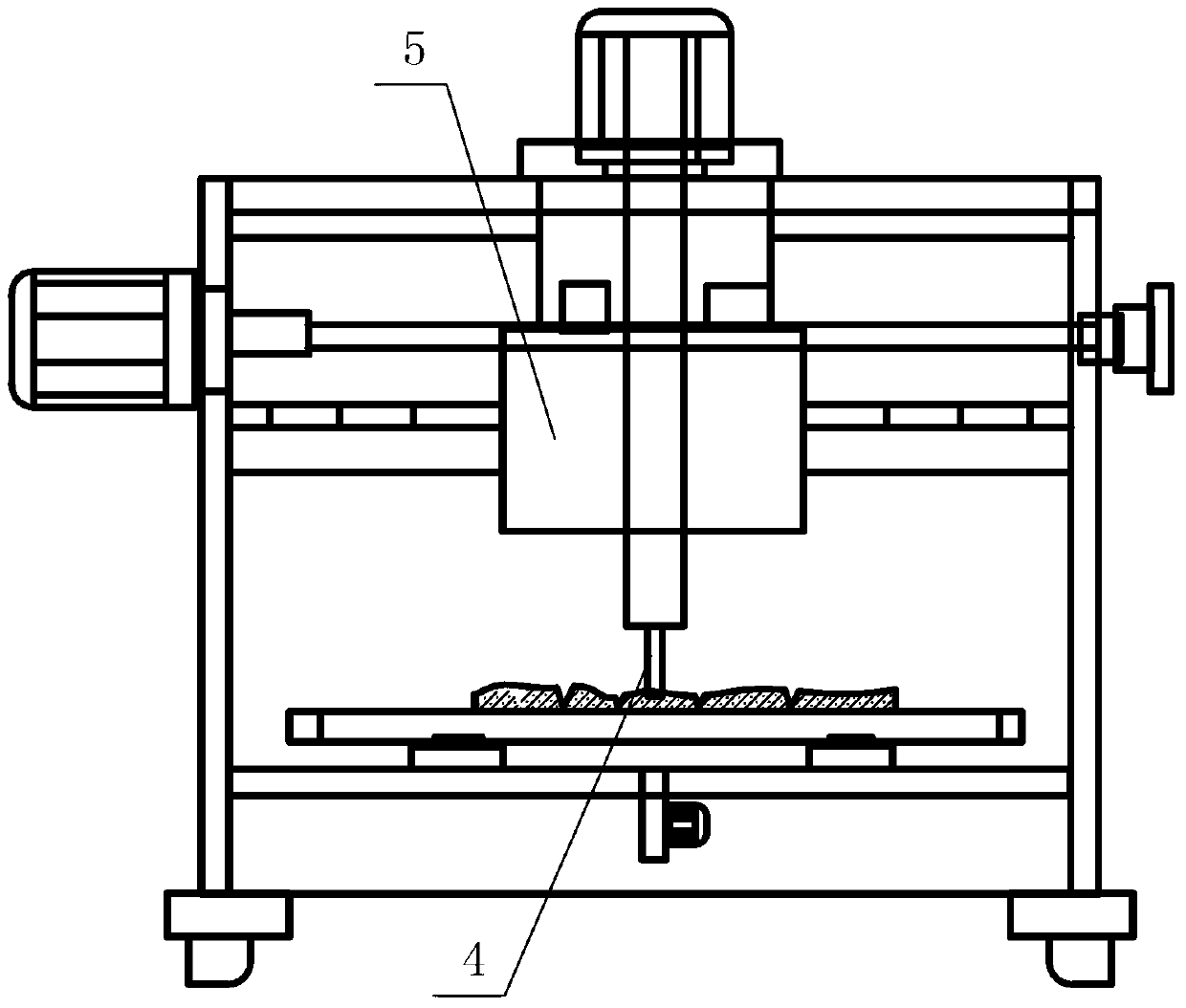

[0020] like Figure 2-4 As shown, the micro-powder engraving distributing device for polished tiles includes a secondary distributing device, and also includes a computer engraving machine and a powder screen printing machine that can move respectively above the cavity of the secondary distributing device. The secondary distributing device includes a distributing vehicle 1 reciprocating and translating on the distributing platform, a mold frame 2 and a bottom mold core 3 that can be lifted, and the mold frame 2 and the bottom mold core 3 constitute a brick pressing mold cavity. The engraving head of the computer engraving machine can realize the adjustment of three-dimensional freedom, including left and right, front and back, and up and down, and can choose different thickness of pen heads according to the needs of pattern design, so as to obtain the required line effect. The engraving pen 4 that is installed in engraving head engraves fabric layer into the hollow line patter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com